Top cover of power battery, assembly method thereof and power battery

A power battery and top cover technology, applied in battery cover/end cover, assembled battery machine, secondary battery manufacturing, etc., can solve the problem of low reliability, inability to guarantee the stability of poles and conductive blocks, poles and conductive blocks The problem of small contact area can achieve the effect of reducing the use of nuts and circlips, good axial positioning effect, and stable and reliable assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

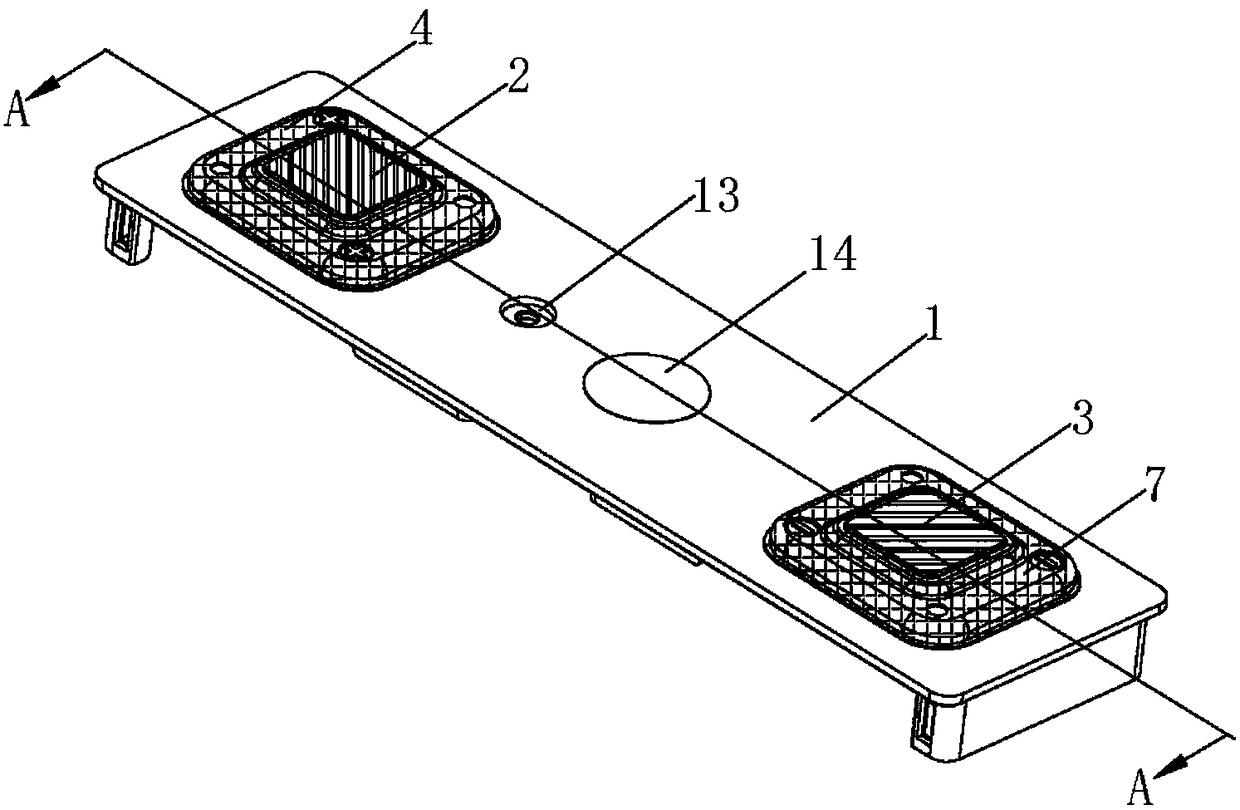

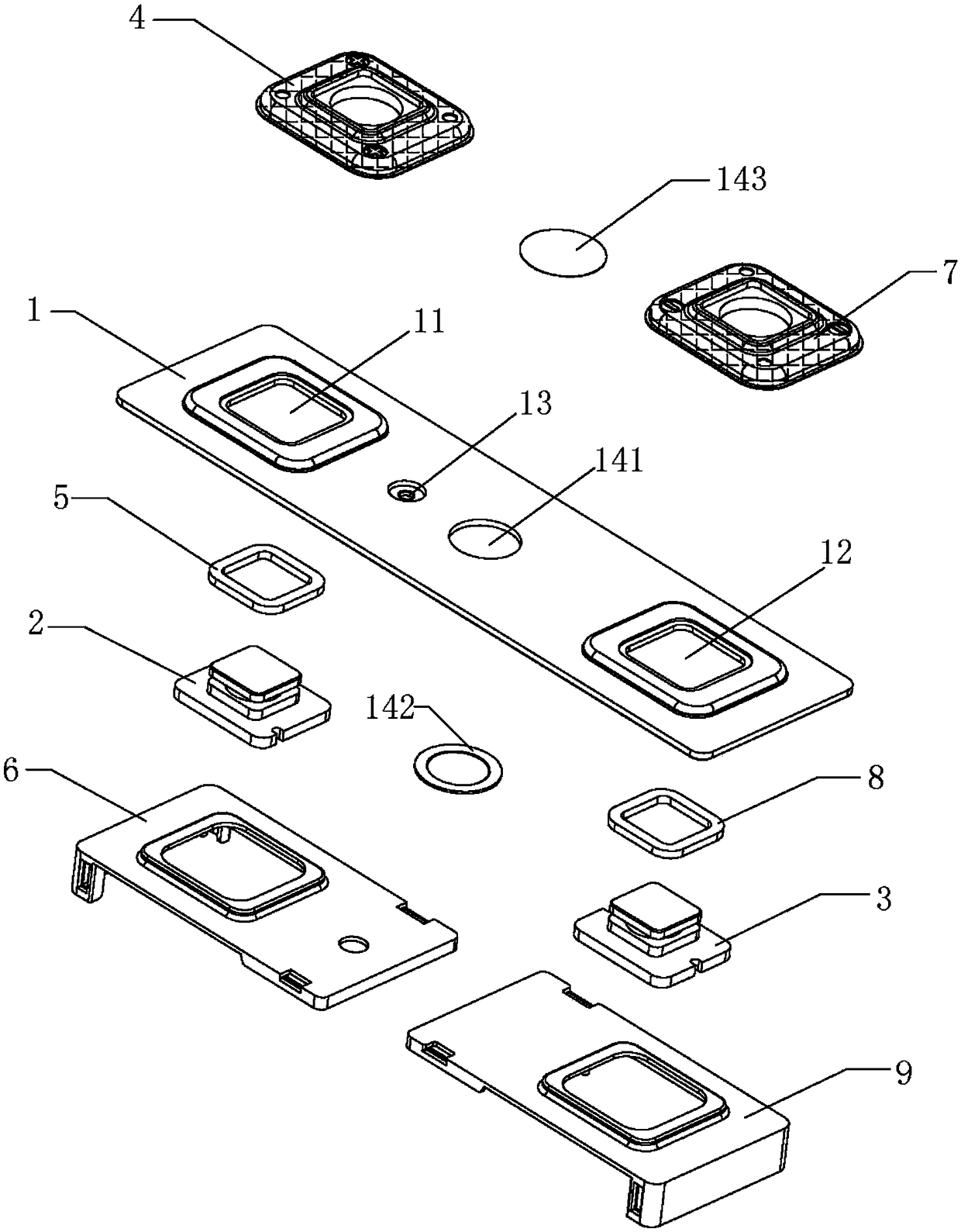

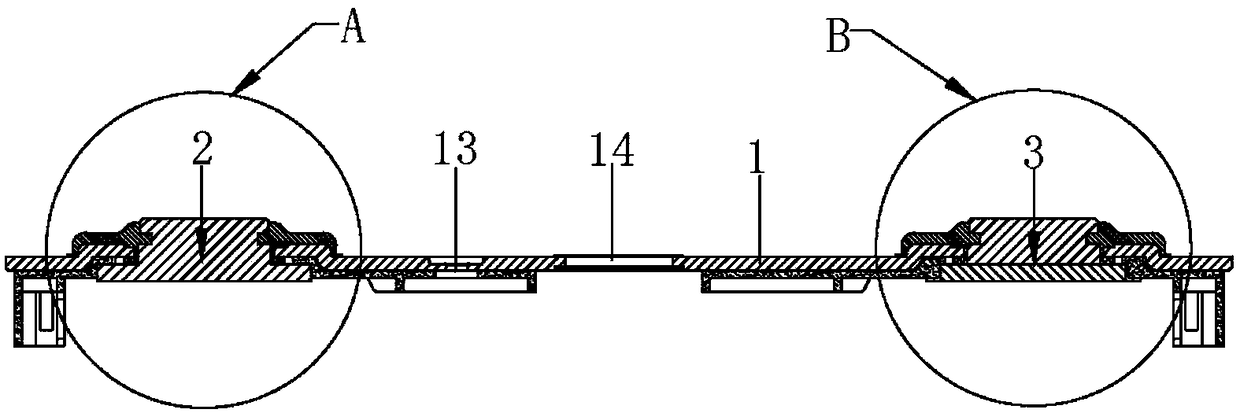

[0042] Such as Figure 1-11 As shown, a power battery top cover includes a top cover sheet 1 and a first pole 2, a second pole 3, a first installation hole 11, a second installation hole 12, and an explosion-proof valve 14 arranged on the top cover sheet 1. And the injection hole 13, the explosion-proof valve 14 includes the explosion-proof hole 141 arranged on the top cover sheet 1, the explosion-proof sheet 142 for sealing the explosion-proof hole 141, and the protective film 143 covering the explosion-proof hole 141; the first pole 2 is installed on the second In a mounting hole 11, the second pole 3 is installed in the second mounting hole 12, the first pole 2 includes a first base part 21 and a second base part 22, and the first base part 21 and the second base part 22 A first cylinder part 23 is arranged between them, and a first card groove is formed between the first base part 21, the first cylinder part 23 and the second base part 22; the first cylinder part 23 is sle...

Embodiment approach 2

[0052] Such as figure 2 As shown, a method for assembling the power battery top cover described in Embodiment 1 includes the following steps:

[0053] Step 1) Set the first sealing ring 5 on the fifth base part 24 of the first pole 2 to form the first pole 2 assembly, and set the second sealing ring 8 on the sixth base part of the second pole 3 34 forming the second pole 3 assembly;

[0054] Step 2) Install the first pole 2 assembly in the first installation hole 11 of the top cover sheet 1, and install the second pole 3 assembly in the second installation hole 12 of the top cover sheet 1;

[0055] Step 3) Install the first insulating member 6 between the second base portion 22, the first sealing ring 5 and the top cover sheet 1, install the third insulating member 9 on the fourth base portion 32, the second sealing ring 8 and between the top cover sheet 1;

[0056] Step 4) Using the overmolding injection molding process respectively, the conductive plastic part 4 is faste...

Embodiment approach 3

[0060] Such as Figure 12 As shown, a power battery includes a bare cell 20, an electrolyte, a battery casing 10 for containing the bare cell 20 and the electrolyte, and a top cover sealed and installed on the battery casing 10, and the positive electrode of the bare cell 20 The ear 30 is electrically connected to the first pole 2 on the top cover, and the negative pole ear 40 of the bare cell 20 is electrically connected to the second pole 3 on the top cover, which is the power battery provided in Embodiment 1 top cover. Compared with the existing power battery, the power battery of the present invention has fewer assembly parts and a compact and reliable structure, which can not only effectively ensure the working performance of the battery, but also effectively improve the production efficiency of the battery and reduce the production cost of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com