Split combined belt pulley

A combined belt and split technology, used in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of difficult, difficult, and impossible to disassemble the pulley, and achieve axial positioning. Convenience, reduce the difficulty of replacement, and simplify the effect of tedious steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

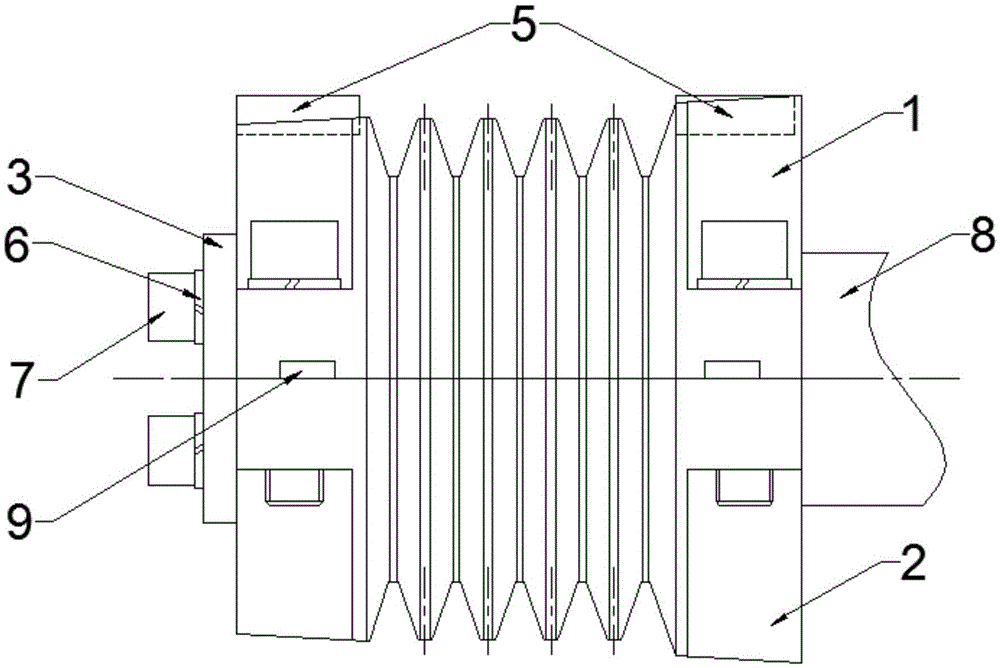

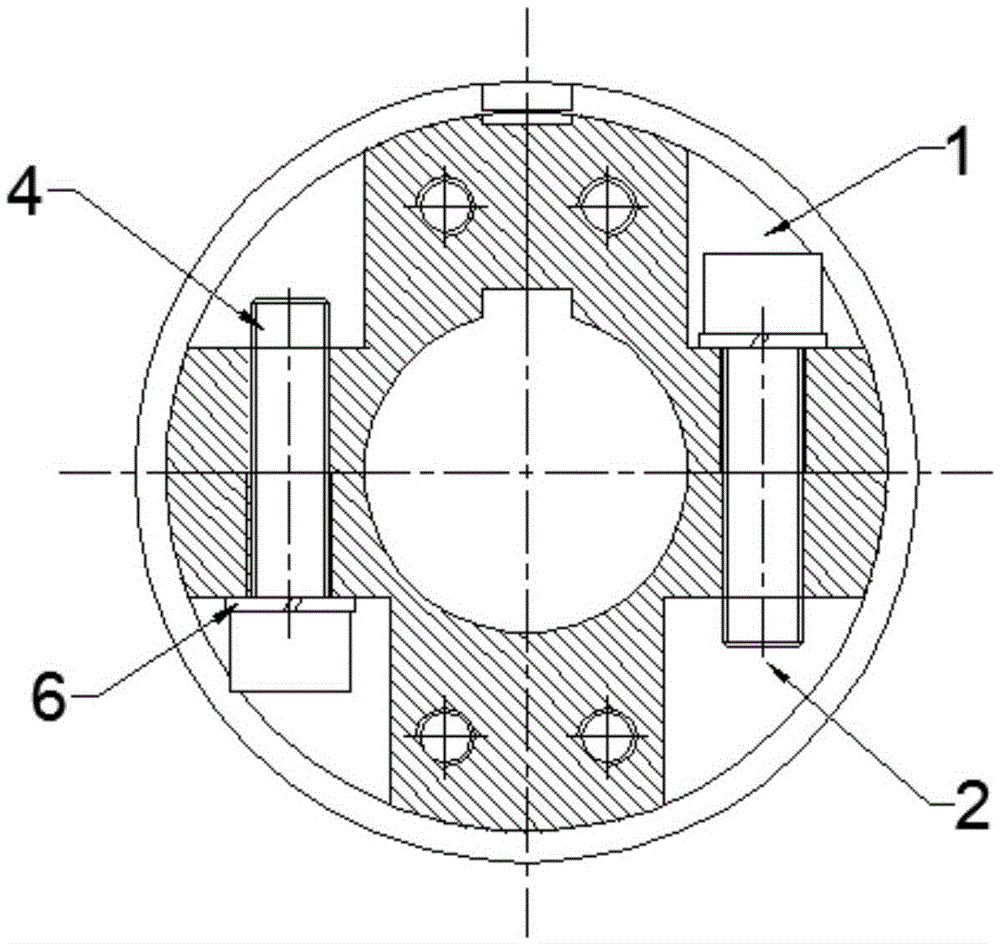

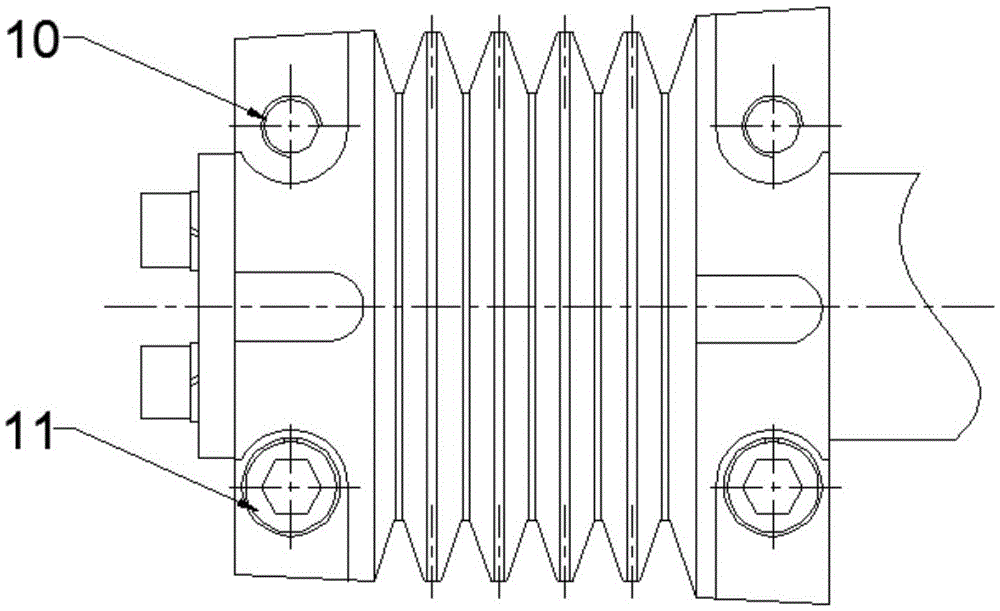

[0035] Such as Figure 1-9 Shown, the present invention is a kind of split type combination belt pulley, comprises half wheel 1 and half wheel 2, and half wheel 1 and half wheel 2 diameters are respectively provided with axial location key 9 and keyway and are mutually assembled dimensions. Openings are provided on both sides of the axial centerline of half-wheel 1 and half-wheel 2, and the bottoms of the two openings located on one side of the axial centerline are provided with through holes 11, which are located on the other side of the central axis. The bottoms of the two openings are provided with threaded holes 10 . The half-wheel 1 and the half-wheel 2 are fixed as a whole by screwing the connecting bolt 4 through the through hole 11 of one said half-wheel and then screwing into the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com