Laughing gas inlet valve

A technology of air intake valve and laughing gas, which is applied in the field of medical equipment, can solve problems such as valve core collision, valve core cannot be positioned, excessive deformation of sealing ring, etc., to avoid excessive deformation, facilitate machining, and axial positioning Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

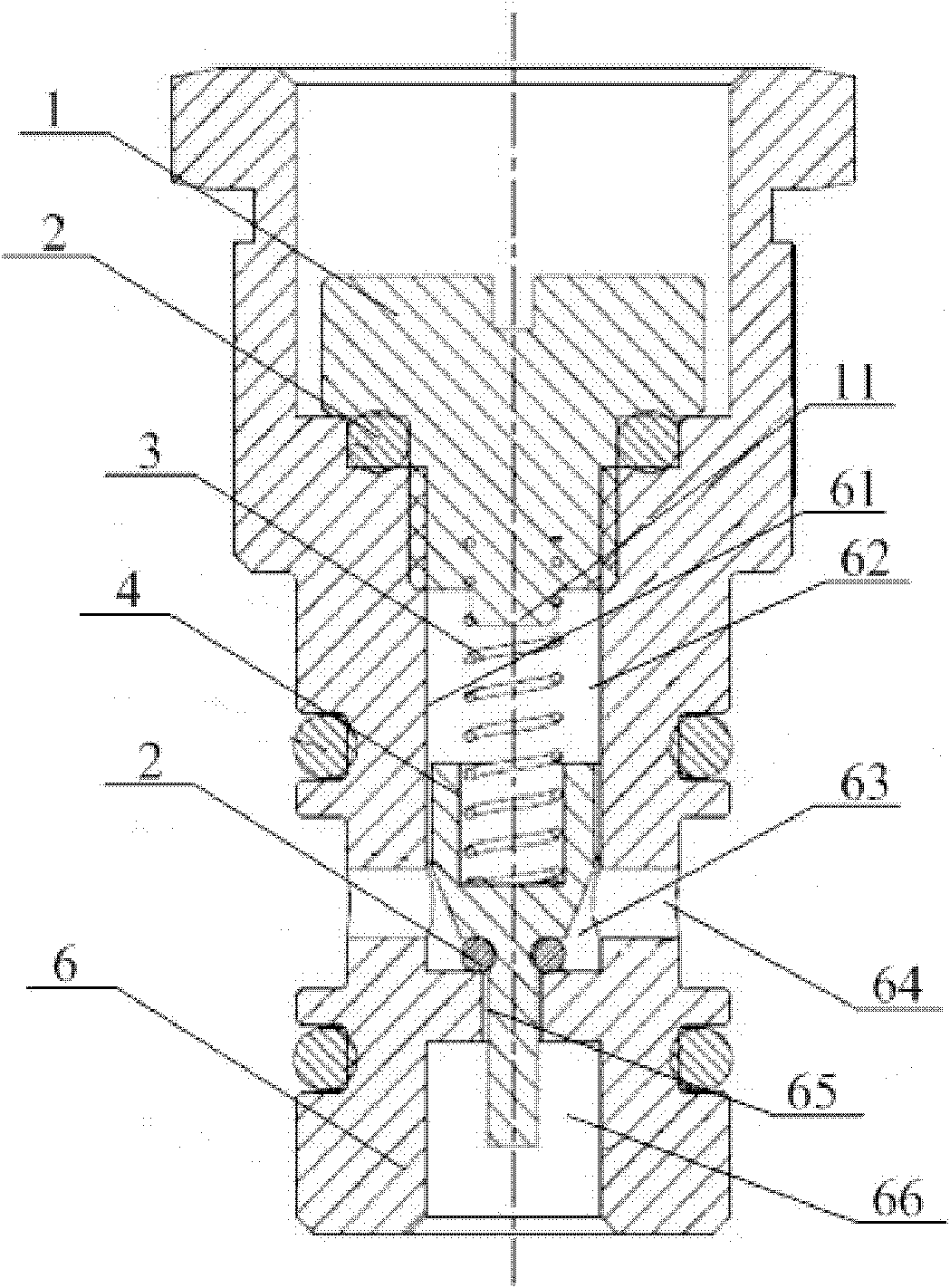

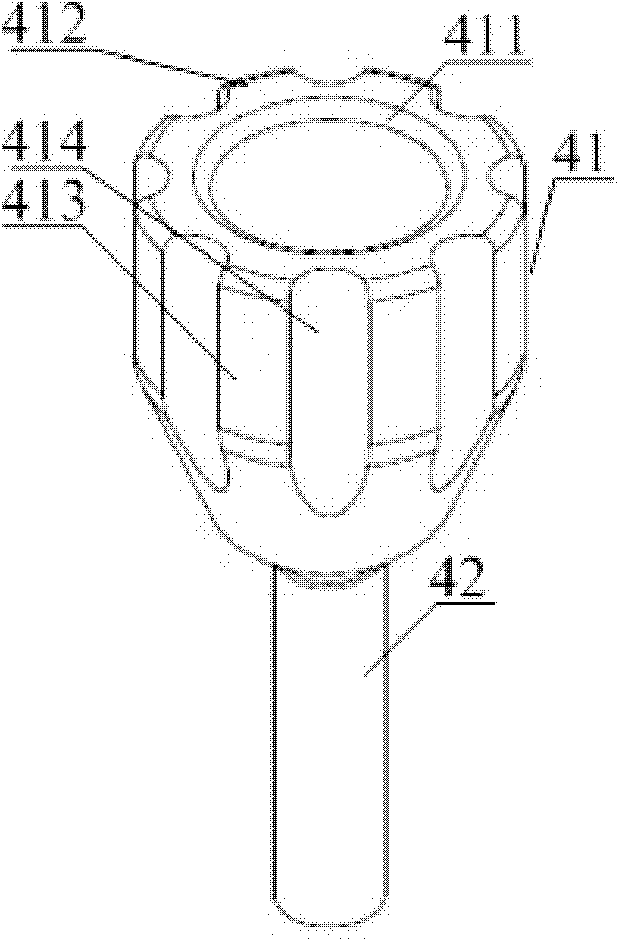

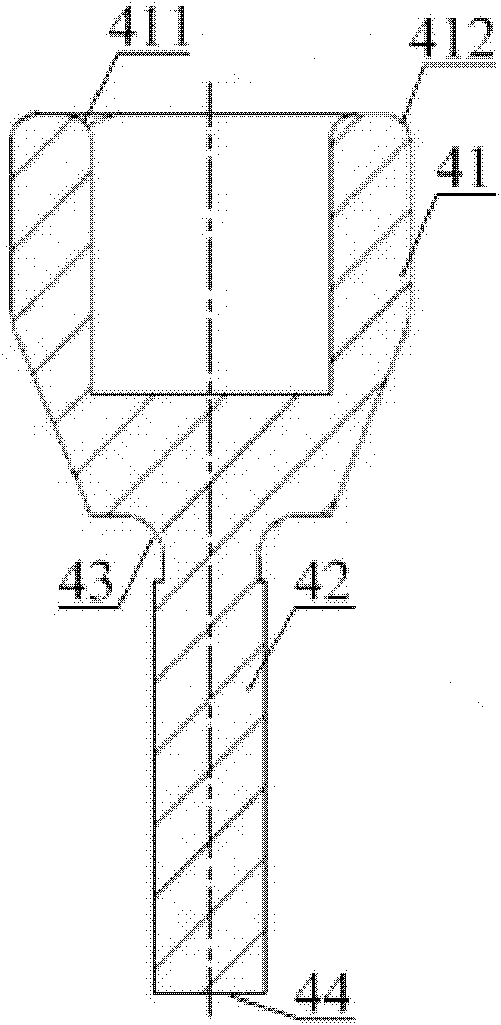

[0035] Such as Figure 1~4 As shown, in this embodiment, the nitrous oxide intake valve of the present invention includes a valve body 6 and a valve core 4, the valve core 4 is arranged inside the valve body 6, and the valve core 4 includes a valve head 41 and a valve stem 42 Two parts, the outer ring of the valve head 41 is evenly provided with a number of semicircular vent holes 414, the valve head 41 is provided with a groove for installing the spring 3, the top end surface of the groove is the upper end surface of the valve core, which has a rounded chamfer The inner edge 411 and the outer edge 412 with arc chamfering, the valve head 41 and the valve stem 42 are connected with an arc-shaped sealing ring boss 43 .

[0036] Wherein, a cavity one 62, a cavity two 63, and an air outlet 66 are sequentially arranged in the valve body 6 from top to bottom, and an air inlet 64 is arranged on the valve body 6, and the air inlet 64 is connected to the cavity two 63, and the cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com