A kind of 3D through-hole superstructure LED chip and preparation method thereof

A technology of LED chips and superstructures, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of lithography process pattern alignment, insulation problems, the actual protection effect of the protective layer metal and stress regulation, etc., to achieve excellent Super-current drive capability, improved current distribution uniformity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

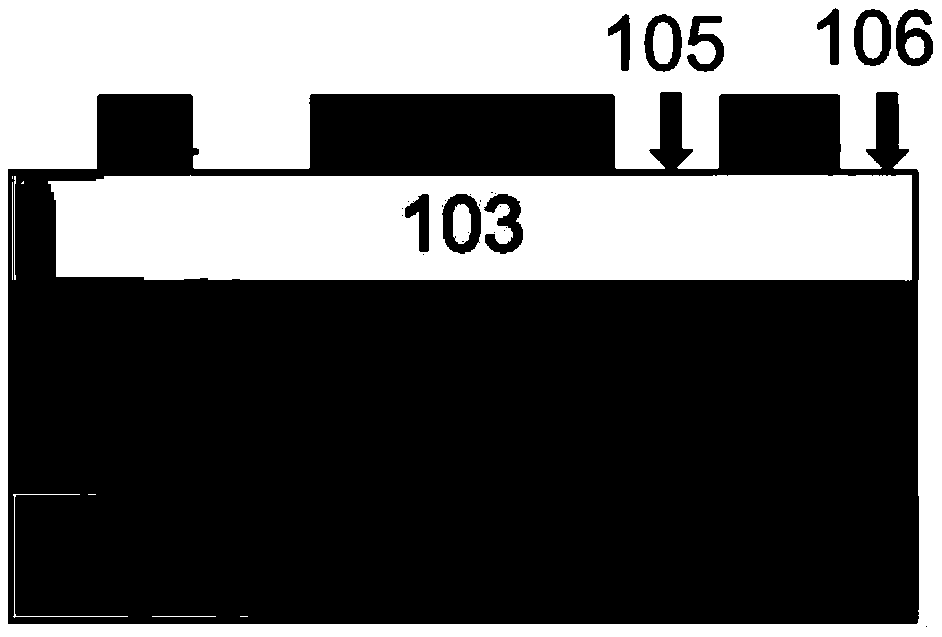

[0067] Such as Picture 11 As shown, a 3D through-hole superstructure LED chip includes a second insulating layer 115, an n-GaN layer 101 (n-type doped GaN film), an InGaN / GaN multiple quantum well layer 102, and a p-GaN layer stacked in sequence 103 (p-type doped GaN film), mirror layer 104, mirror protection layer 107, first insulating layer 111, first bonding layer 114, second bonding layer 201, bonding substrate 200, and back gold layer 202; the mirror layer 104 is provided with a first opening 105 and a second opening 106, the second opening 106 is located at the edge of the mirror layer 104; the mirror protection layer 107 is provided on the mirror layer 104 and covers the first The bottom and sidewalls of the opening 105 and the bottom and sidewalls of the second opening 106 are covered; the mirror protection layer 107 is provided with a third opening 108 and a walkway 109, the third opening 108 and the first opening 105 Passing through up and down, the walkway 109 is ci...

Embodiment 2

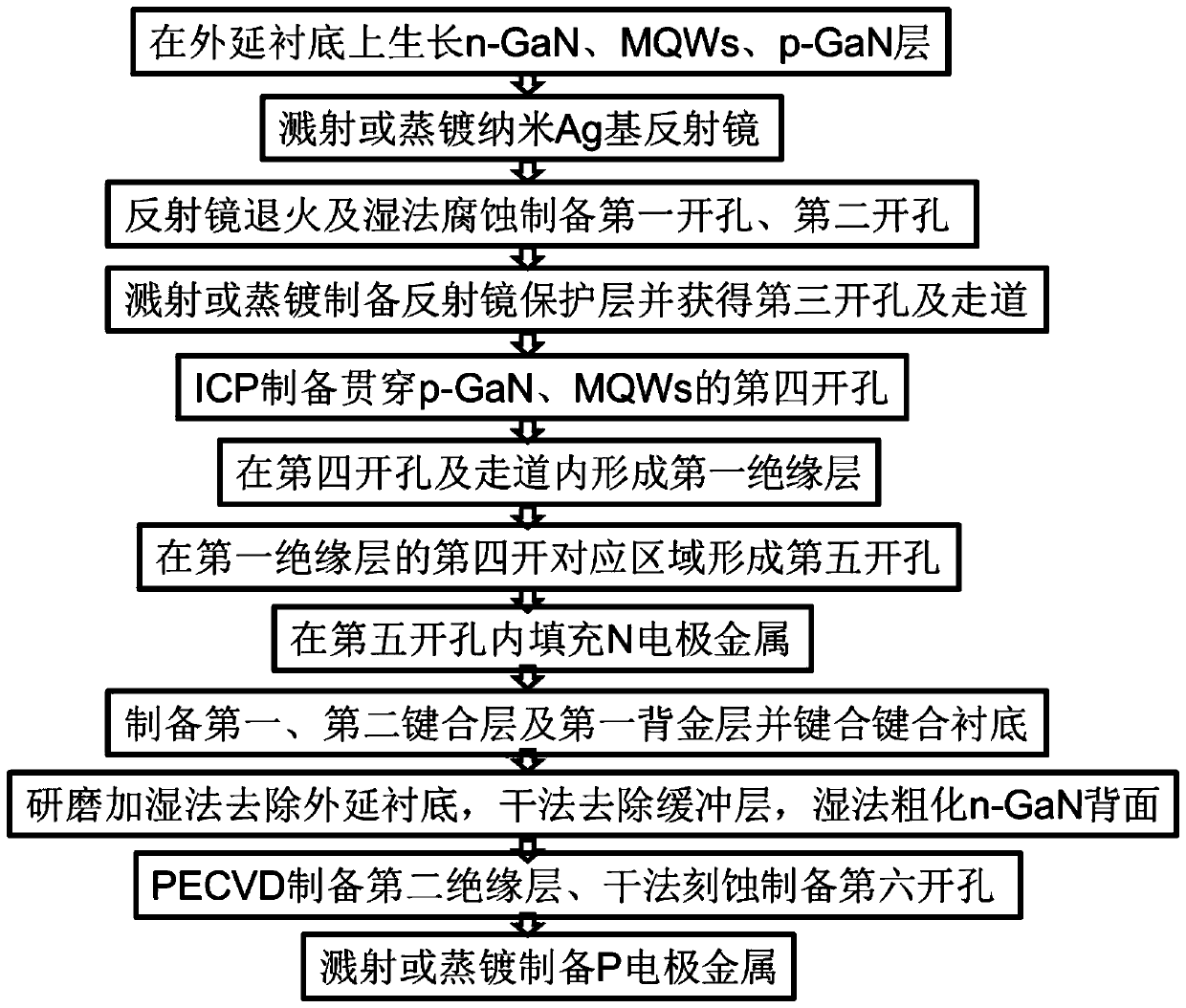

[0077] Such as Figure 1-11 As shown, a method for preparing a 3D through-hole superstructure LED chip includes:

[0078] The epitaxial growth step: take the epitaxial substrate, and sequentially grow the n-GaN layer 101, the InGaN / GaN multiple quantum well layer 102 and the p-GaN layer 103 on the epitaxial substrate;

[0079] Evaporation and hole-opening step: vapor-deposit a mirror layer 104 on the p-GaN layer 103, and after high-temperature annealing, a first hole 105 and a second hole 106 are opened on the mirror layer 104, and the second hole 106 is located in the reflective layer. The edge of the mirror layer 104;

[0080] Step of preparing a mirror protection layer 107: preparing a mirror protection layer 107 on the mirror layer 104, and the mirror protection layer 107 covers the bottom and side walls of the first opening 105 and the bottom and sides of the second opening 106 Wall; Next, a third opening 108 and aisle 109 are provided on the mirror protection layer 107, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com