Dry type high-voltage current transformer

A high-voltage current and transformer technology, applied in the direction of inductors, transformers, transformer/inductor coils/windings/connections, etc., can solve problems such as shedding, reduced safety of current transformers, and large ladder differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

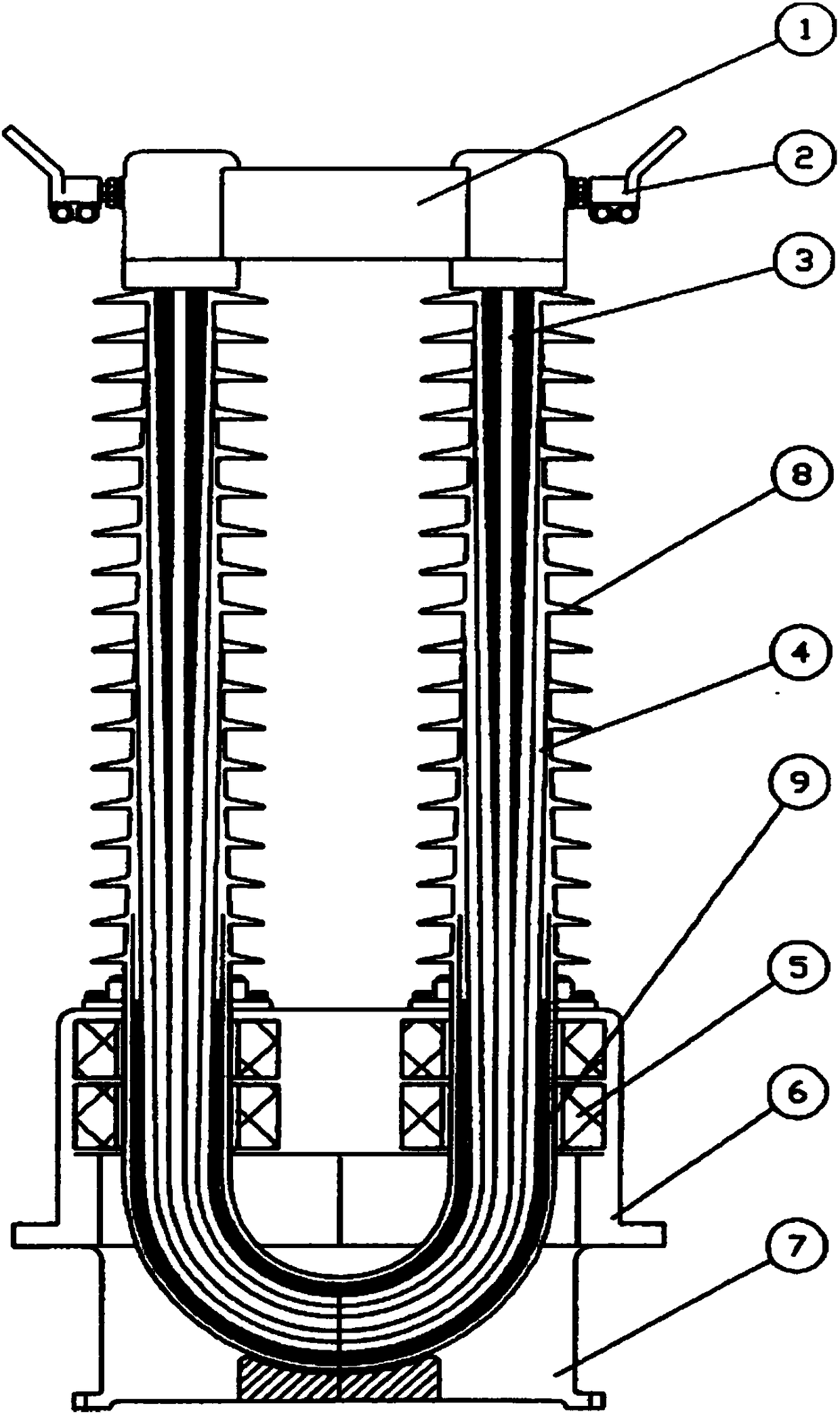

[0018] The present invention is composed of a connector 1 , a connection terminal 2 , a primary conductor 3 , an insulating wrapping layer 4 , a secondary winding 5 , a box body 6 , a base 7 and an outer insulating sheath 8 . The primary conductor 3 adopts a rod-shaped or tubular conductor, and several secondary windings 5 are placed in the ground screen part of the insulating wrapping layer 4, and are firmly fixed with the base 7 and the outer insulation 8. The primary conductor acts as a conduction current, passing through The secondary coil makes the secondary coil generate induced current. The connector 1 is a component that connects the two terminals of the primary conductor 3, has a certain mechanical strength, strengthens the function of fixing and provides space for switching current. When it is solid, it only plays the role of strengthening and fixing, and can be simplified into a plate shape; when it is hollow, the conductor is tubular, and there are conductors in ...

Embodiment 2

[0020] The primary conductor 3 is made by adding a conductor inside a tubular conductor, and several secondary windings 5 are placed in the ground screen part of the insulating wrapping layer 4, and are firmly fixed with the base 7 and the outer insulation 8. The connector 1 is a member connecting the four terminals of the primary conductor 3, has a certain mechanical strength, and is a hollow structure. All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com