Graphite Expansion Experimental Electric Furnace

A technology of puffing furnace and graphite, which is applied in inorganic chemistry, carbon compounds, chemical industry, etc., can solve problems such as long heating time, hidden safety hazards, and affecting heating efficiency, and achieve simplified operation, good heat insulation effect, high precision and The effect of response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

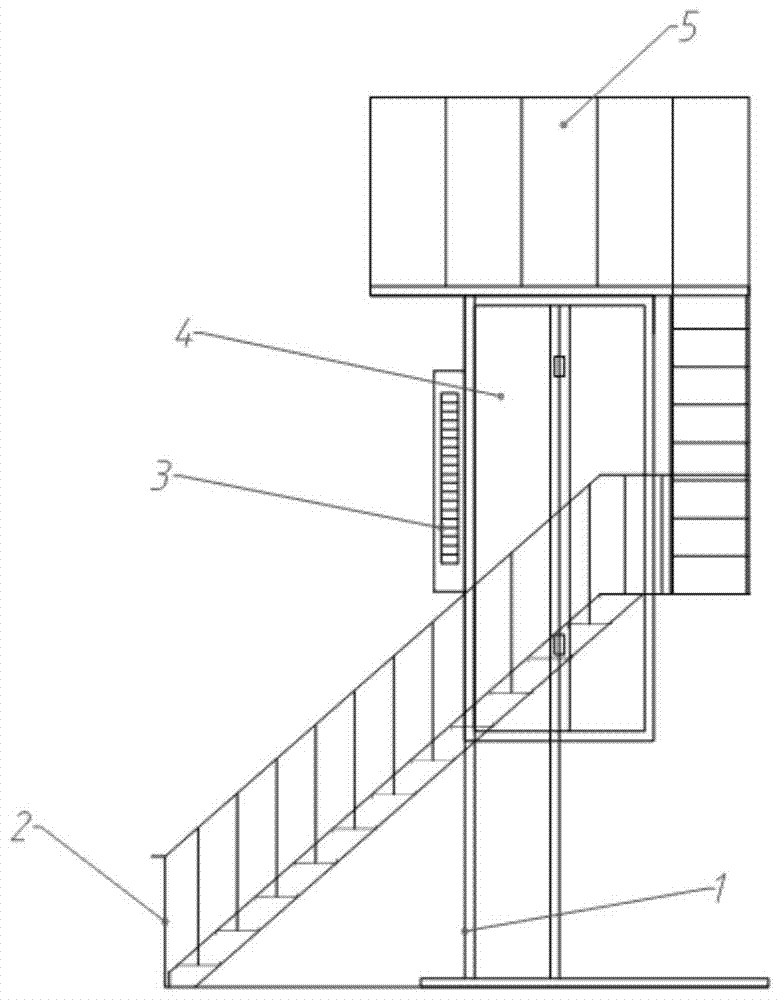

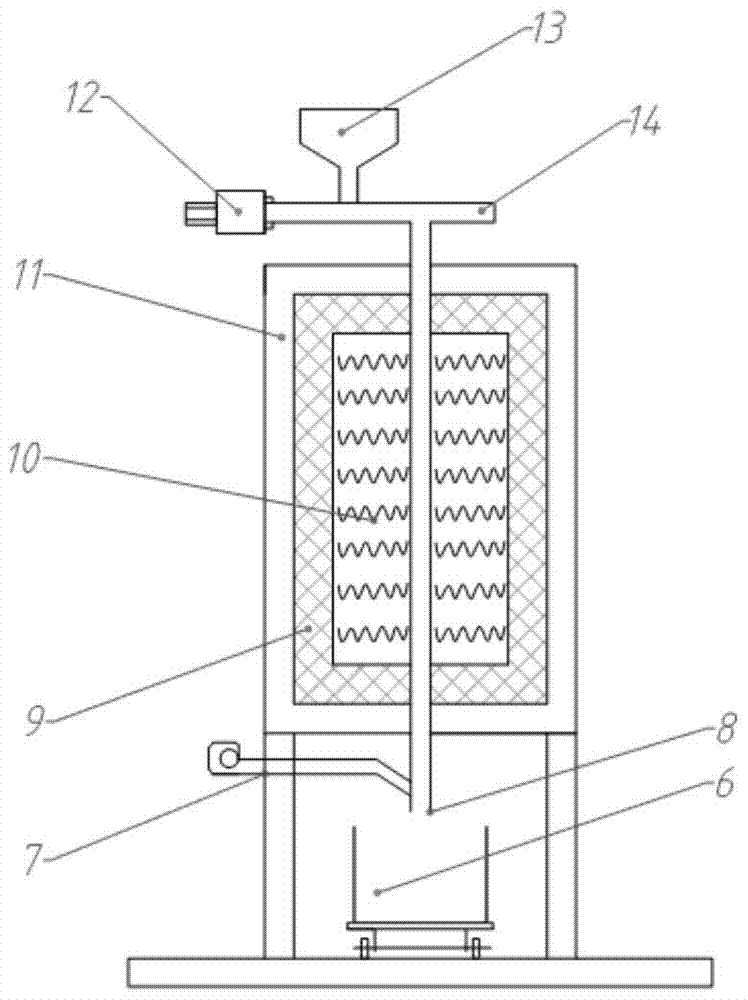

[0012] see figure 1 , figure 2 , the present invention has body of furnace 4, and the lower end of body of furnace 4 is provided with material receiving bucket 6, jet fan 7, high-temperature stainless steel puffing pipe, body of furnace 4 upper ends are connected with feeding device 12, graphite enters feeding device from hopper 13, passes Feeding screw 14 controls the feed flow rate and keeps stirring to prevent the feed port from being blocked. Graphite enters the interior of the furnace body 4 and is rapidly heated and expanded by the heating element 10. The outer side of the heating element 10 is wrapped with an insulating layer 9 to prevent heat dissipation and effectively improve heating efficiency. The heated and expanded graphite flows out from the high-temperature stainless steel expansion tube 8, and the outlet flow is controlled by the jet fan 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com