Mat grass harvesting and drying process

A mat and process technology, which is applied to the field of mat mat harvesting and drying technology, can solve the problems of prolonging drying time, reducing drying temperature, and varying degrees of drying, so as to speed up the bundling speed, improve the bundling efficiency, and improve the drying efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, a process for harvesting and drying mat grass comprises the following steps;

[0051] (1) After harvesting and cleaning the mat grass, after removing unqualified mat grass such as withered yellow grass, broken grass, and short grass, use the mat grass automatic binding equipment to bundle into straw handles, place the straw handles vertically, and drain the water;

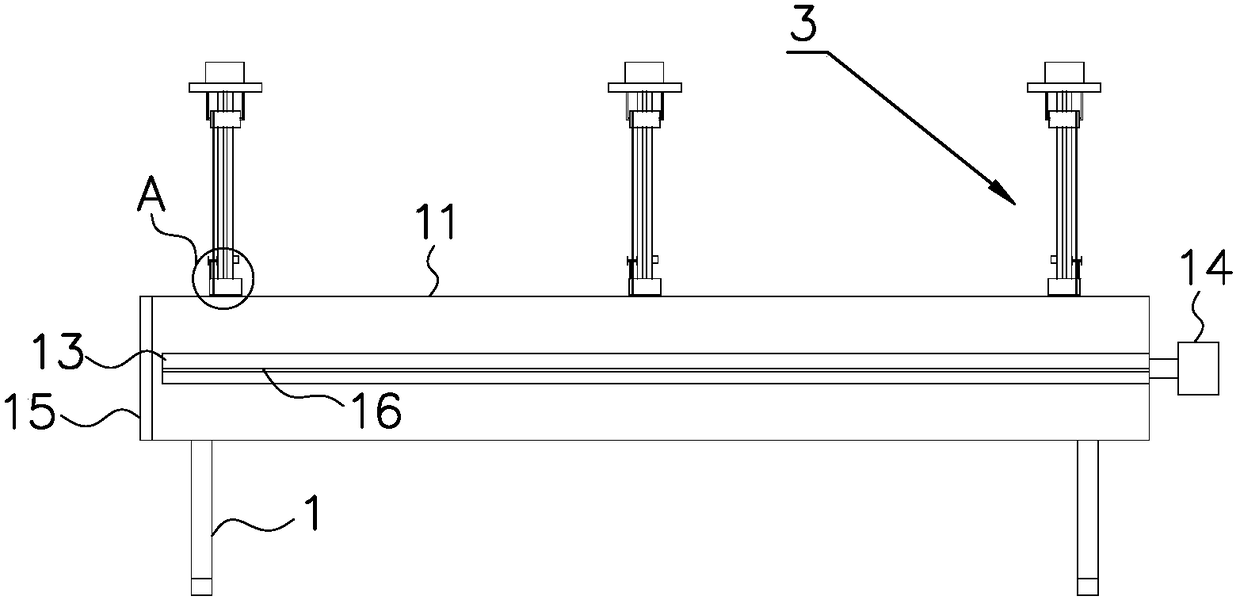

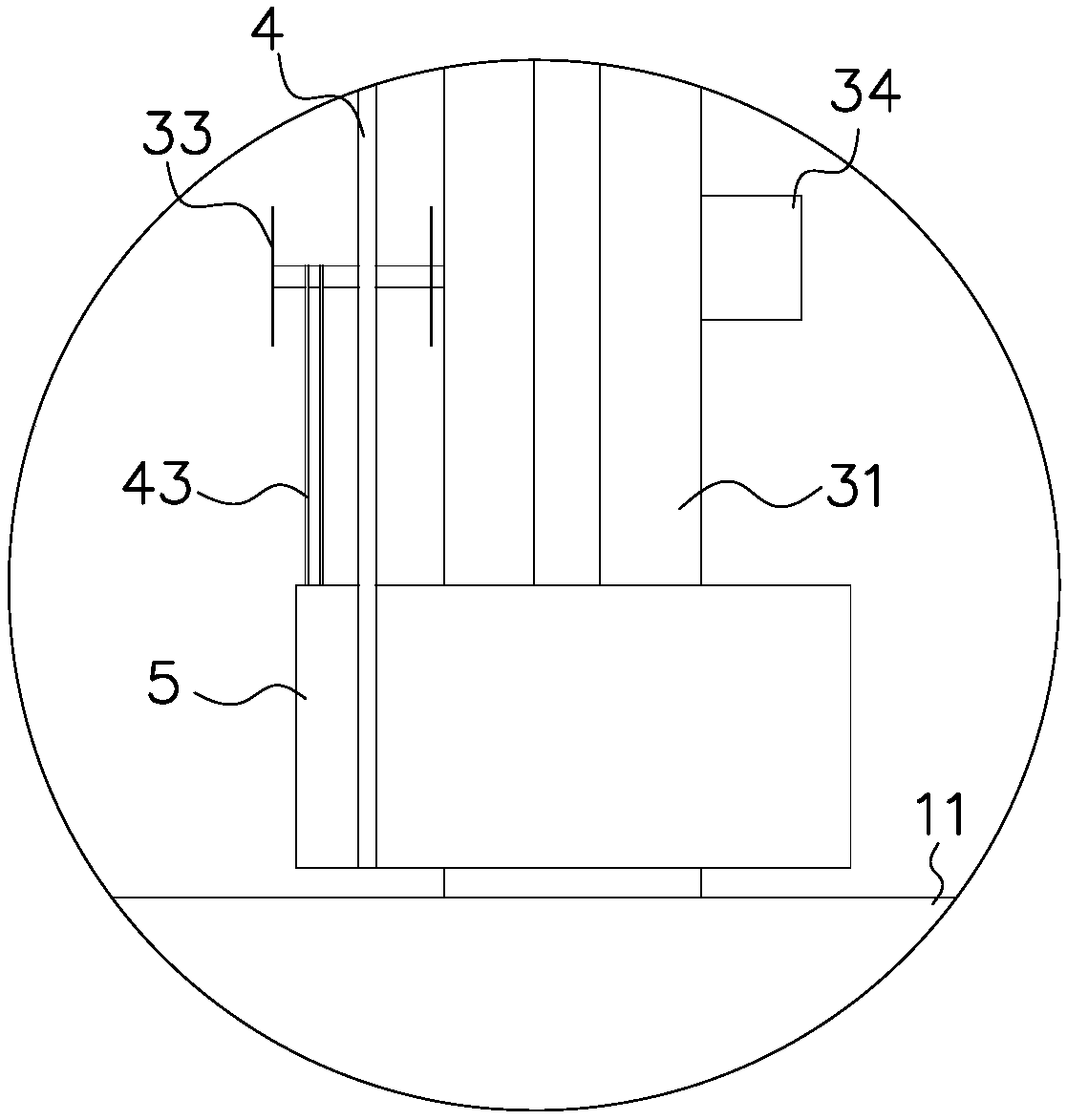

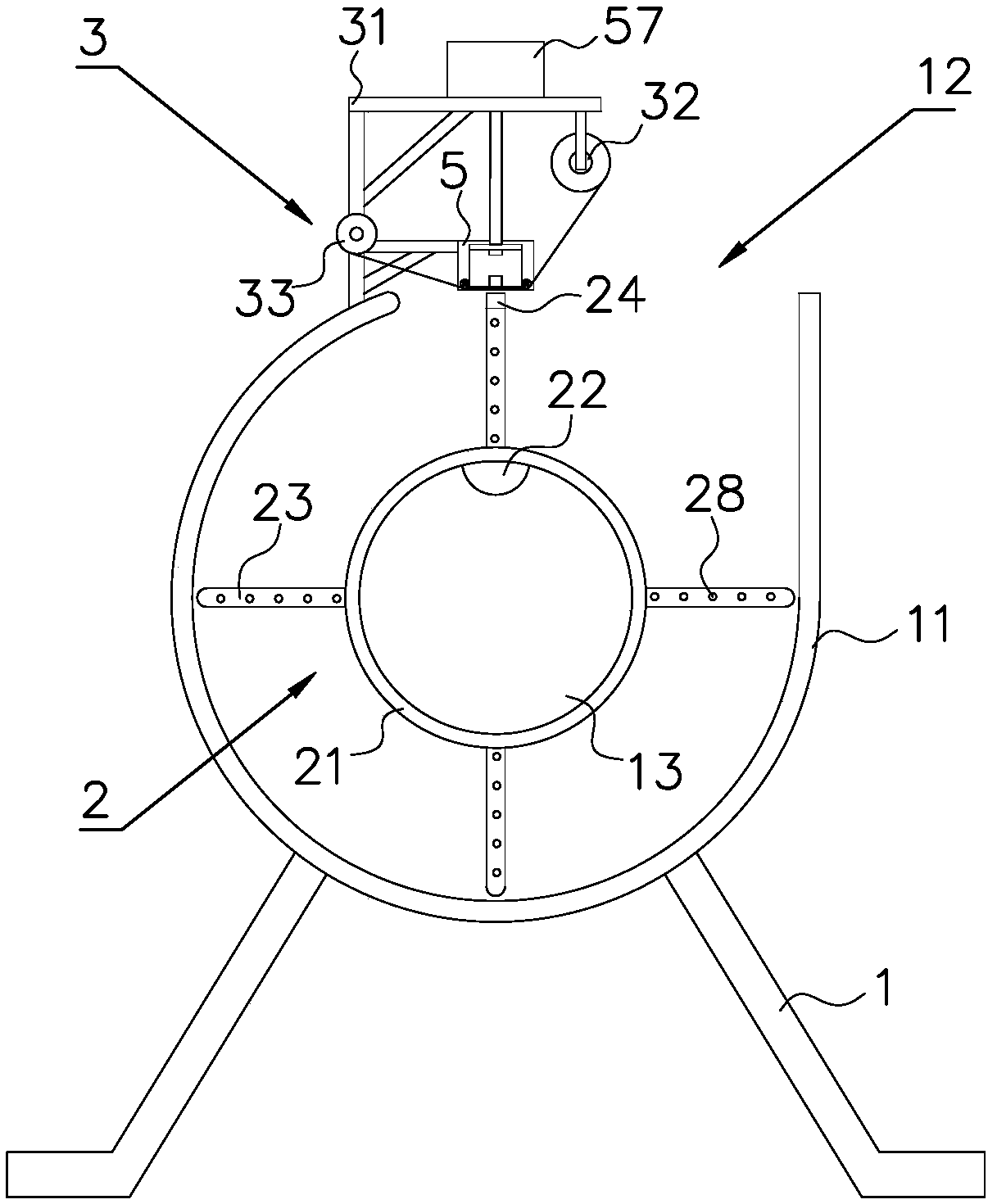

[0052] like figure 1 As shown, the mat automatic binding equipment of this embodiment includes a frame 1, on which a cylindrical base 11 is horizontally arranged, and a strip-shaped mat inlet 12 is provided on the top of the base 11 . The base 11 is provided with a central shaft 13 that rotates with the base 11. The extension direction of the central shaft 13 is the same as that of the base 11. One end of the base 11 is equipped with a first motor for driving the central shaft 13 to rotate. 14, and the other end is equipped with an openable end cover 15.

[0053] like image 3 As shown...

Embodiment 2

[0074] A kind of mat grass drying process of the present embodiment comprises the following steps:

[0075](1) After the mat grass after harvesting and cleaning is removed from unqualified mat grass such as withered yellow grass, broken grass, and short grass, it is bundled into grass with the mat grass automatic binding equipment (mat grass automatic binding equipment identical to embodiment 1) put, drain;

[0076] (2) Put the straw upright in an oven preheated to 85°C (the same oven as in Example 1), bake for 25 minutes, then cool down to 70°C, continue to bake for 3 hours, and then cool down to room temperature naturally , you can take out the grass handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com