Potato secondary soil screening harvesting cart

A potato and harvesting technology is applied in the field of potato secondary soil screening and harvesting vehicles, which can solve the problems of unsatisfactory soil and potato separation effect, low working efficiency and high rate of potato injury, and achieves good soil screening effect, improved efficiency and potato injury rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

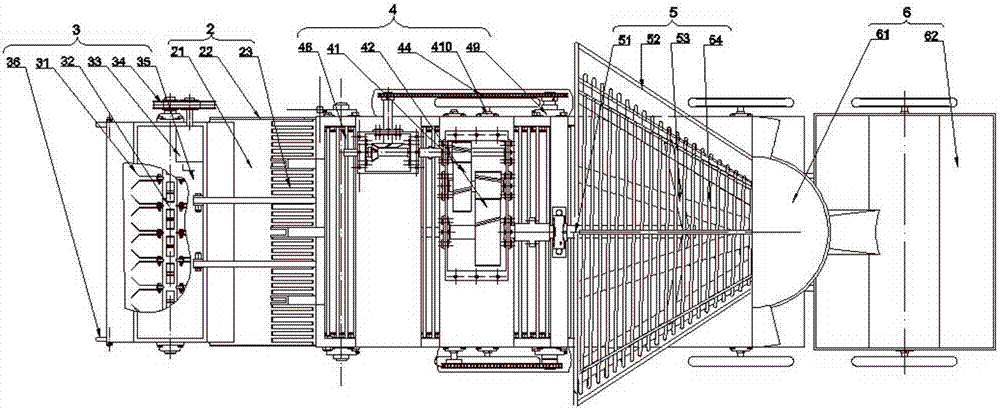

[0027] Embodiment 1, the present invention it comprises vehicle frame device 1, digging device 2, removes seedling device 3, soil and potato shakes and separates conveying device 4, spiral drum separation and screening device 5 and collection device 6; Said digging device 2 is positioned at frame device 1; the seedling removing device 3 is located above the excavating device 2; the soil and potato shaking separation conveying device 4 is located at the rear of the excavating device 2, at the center of the frame device 1; the spiral drum separating and screening device 5. The collection device 6 is respectively designed in the rear part of the harvesting vehicle in order, and the collection device 6 is connected to the frame device 1 through a "Jane's coupler". refer to Figure 1 to Figure 6 .

Embodiment 2

[0028]Embodiment 2, the vehicle frame device 1 includes a bearing support plate 11, a square bracket 12, a reducer base 13, a traction device connecting frame 14, a traction frame 15 for a rice seedling remover, support plates 16 on both sides and a frame 17; The bearing support plate 11 is located on the upper part of the soil and potato shaking separation conveying device 4, close to the spiral drum separation and screening device 5, and plays a role in supporting and positioning the bearing connected to the transmission shaft 51. The square bracket 12 is welded between the support plates 16 on both sides. Above, the reducer base 13, the traction device connecting frame 14, and the traction frame 15 of the seedling remover are arranged on the square bracket 12 in turn, except that the reducer base 13 is connected by bolts, and the rest are connected by welding, and the frame 17 is located at At the bottom, all parts are installed on the frame 17, which plays a supporting role...

Embodiment 3

[0029] Embodiment 3, the excavation device 2 is located at the front part of the foundation frame part 1, and the excavation device 2 includes an excavation shovel 21, a shovel handle 22, and a soil filter bar 23 after the shovel; the excavation shovel 21 passes through the shovel handles on both sides 22 is connected on the frame device 1, and the excavating shovel 21 is connected with the shovel rear soil filter grid bar 23, and the shovel rear filter soil grid bar 23 is connected with the soil and potato shaking separation conveying device 4, and the excavation shovel 21 is inclined downward below the horizontal plane Arrangement, adjustable inclination. It is used to shovel out potato pieces and seedlings from the ground; the digging shovel is lower than the horizontal surface, and the shovel head shovels out the potatoes while the harvesting vehicle is advancing. Handle 22 is connected with frame and excavating shovel 21, after potato is shoveled out, be brought into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com