Sugarcane combine harvester with tail cutting device

A combined harvester and tail-docking technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of not being able to cut off tender stems, and leaves are not clean, so as to achieve good tail-docking effects, save costs, and The effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

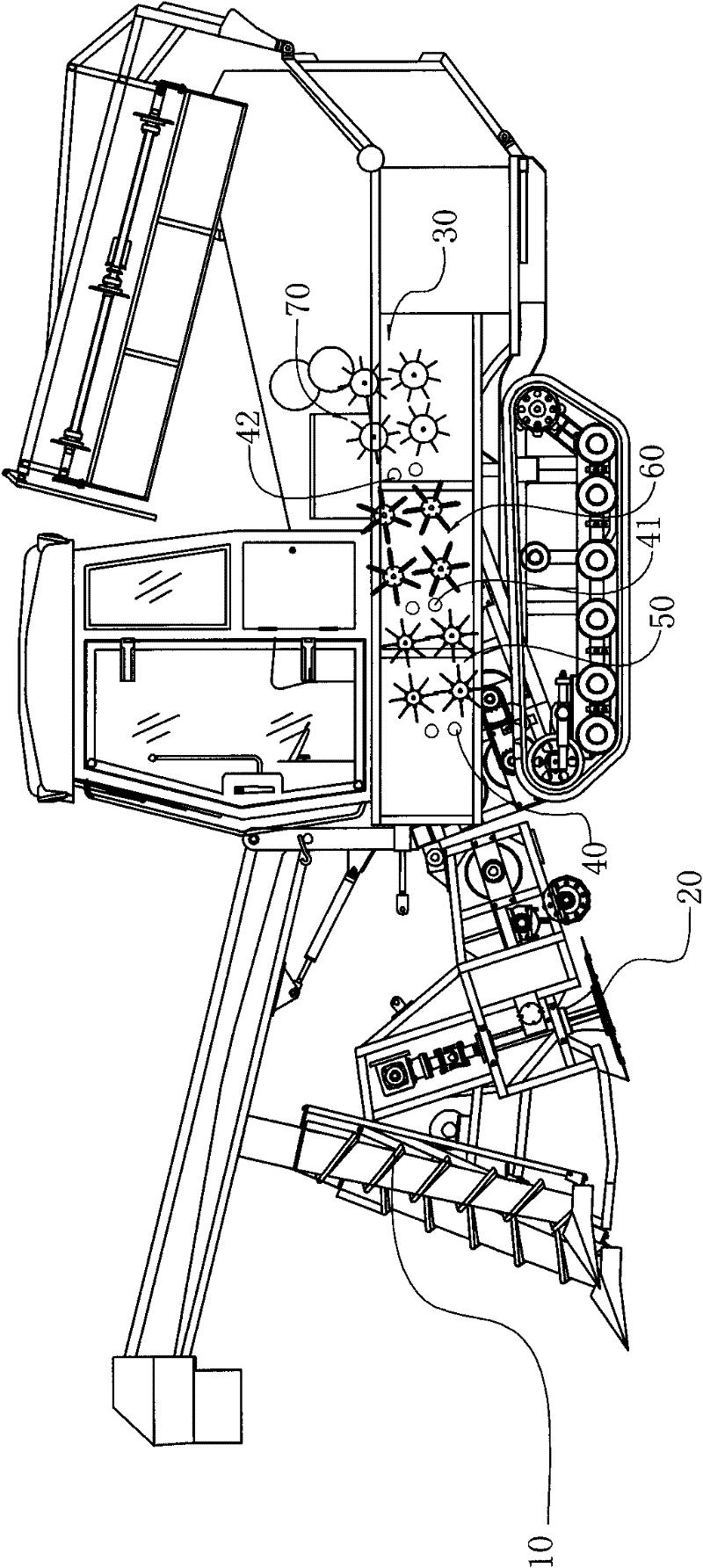

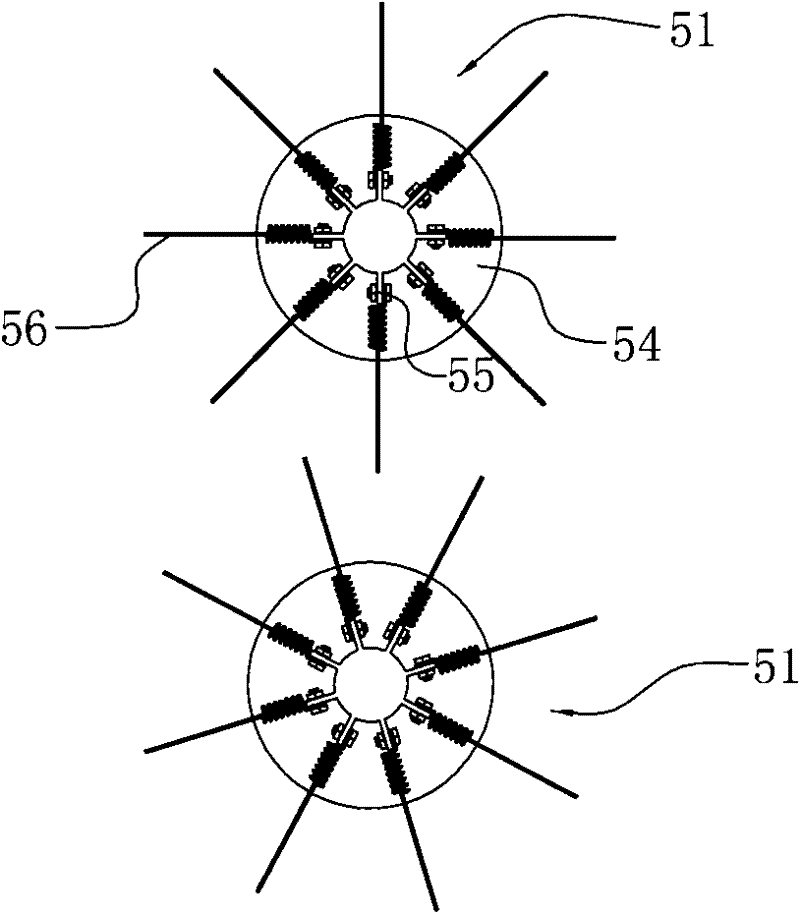

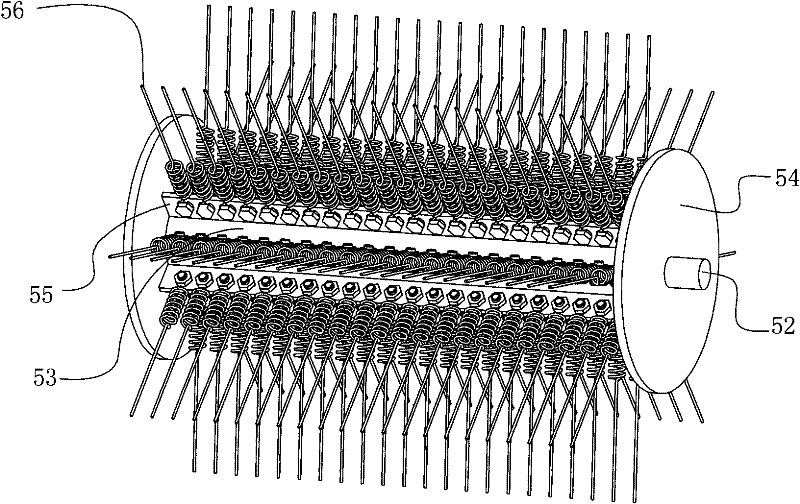

[0031] Sugarcane combine harvester of the present invention, as figure 1 As shown, it includes a power system, an operating system, a front folding mechanism 10, a cutting mechanism 20, and a leaf stripping and tail cutting mechanism 30 arranged behind the cutting mechanism 20. There is a sugarcane transmission channel in the described leaf stripping and tail cutting mechanism 30, and the sugarcane A first transmission wheel 40 , a leaf crushing device 50 , a second transmission wheel 41 , a leaf stripping brush device 60 , a third transmission wheel 42 and a tail breaking device 70 are sequentially provided in the transmission channel. Sugarcane is cut off from the ground by front gathering mechanism 10 and cutting mechanism 20, and then the sugarcane transmission passage of stripping leaf and tail breaking mechanism 30 is stripped and tailed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com