A prefabricated steel box shed hole and construction method suitable for emergency rescue and disaster relief

A prefabricated and shed-hole technology, which is applied in the field of prefabricated steel box sheds and construction for emergency rescue and disaster relief, can solve the problems of high construction safety risk, poor impact resistance, poor adaptability, etc. The effect of strong impact ability and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

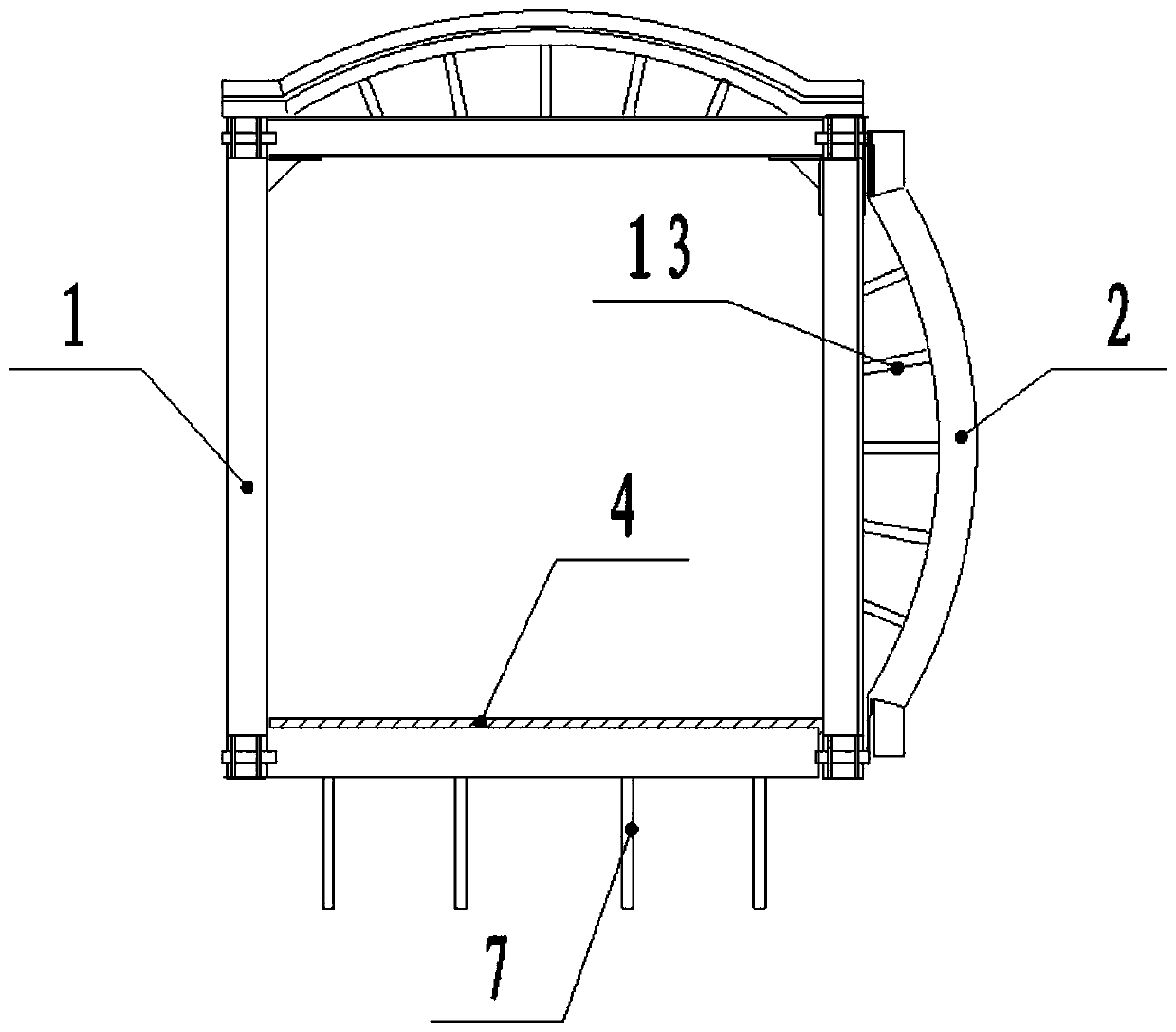

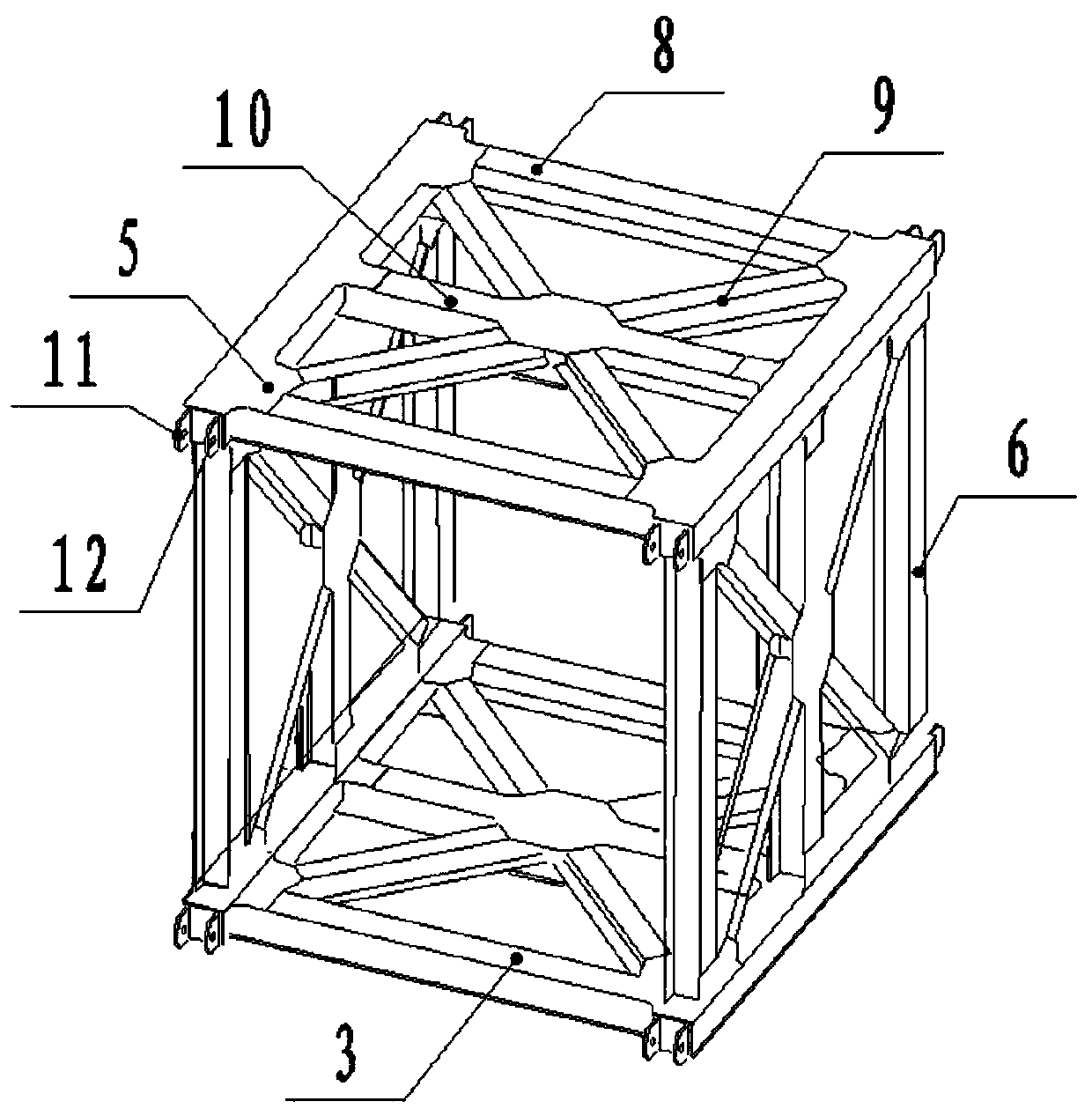

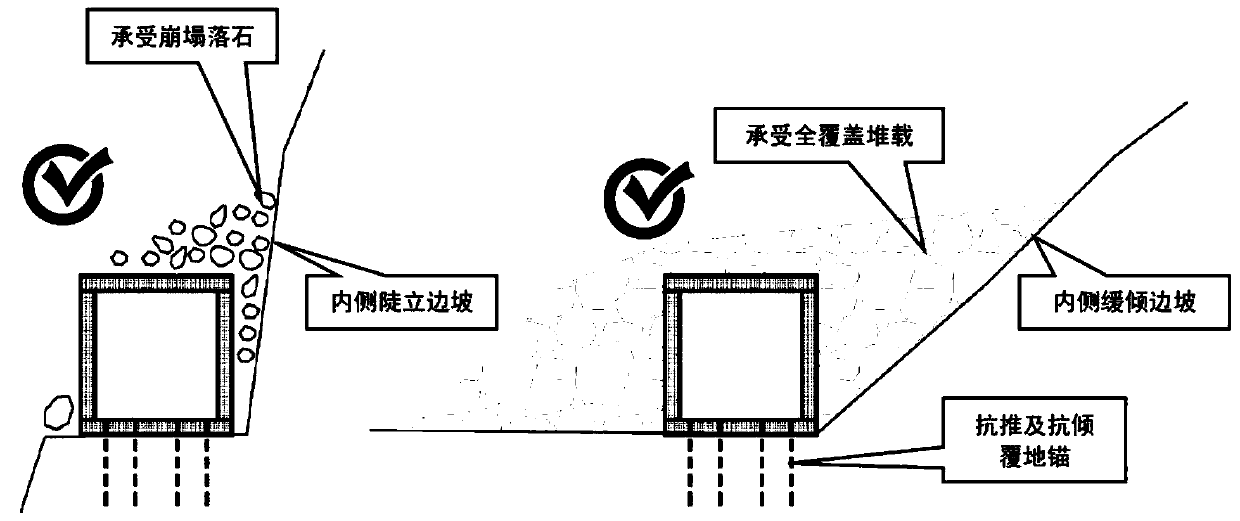

[0044] like Figure 1-3As shown, the present invention is an assembled steel box shed suitable for emergency rescue and disaster relief, including a rectangular frame main body 1 and a buffer armor 2. The bottom frame 3 of the main body 1 is poured with a bottom plate 4 for pedestrians or vehicles to pass through, and the bottom plate 4 is used as the road surface of the protective passage. The top frame 5 of the rectangular frame main body 1 and the side frame 6 on the mountain side are equipped with Buffer armor 2. The top surface of the steel box shed and the side of the mountain are equipped with buffer energy-dissipating devices to make it the armor of the main structure. After falling rocks hit the buffer device, the impact force can be greatly reduced, thereby protecting the main structure. The buffer device allows broken, easy to replace. The bottom side of the bottom frame 3 of the rectangular frame main body 1 is uniformly arranged with a plurality of steel pipe pil...

Embodiment 2

[0054] like Figure 1-3 As shown, a construction method for a prefabricated steel box shed suitable for emergency rescue and disaster relief, including steps:

[0055] Step 1) Prefabricate the structure of the rectangular frame main body 1, the rectangular frame main body 1 is welded or screwed; the buffer armor 2 and the buffer strut 13 are installed outside the top frame 5 of the rectangular frame main body 1 and the side frame 6 on the mountain side;

[0056] Step 2) Use mechanical equipment to clean up the obstacles on the section 1 of the main body of the rectangular frame that needs to be installed, and level off the roadbed;

[0057] Step 3) Install the section length of the rectangular frame main body 1 according to the needs, determine the setting quantity of the rectangular frame main body 1, and then use mechanical equipment to lift or push each segment of the assembled rectangular frame main body 1 into place. The main body (1) of the segmental rectangular frame i...

Embodiment 3

[0062] like Figure 1-3 As shown, a construction method for a prefabricated steel box shed suitable for emergency rescue and disaster relief, including steps:

[0063] Step 1 Prefabricating the structure of the main body 1 of the rectangular frame, the main body 1 of the rectangular frame is welded or screwed;

[0064] Step 2: Clean up obstacles on section 1 of the main body of the rectangular frame, and level the roadbed; mechanical equipment (forklifts) can be used to clean up obstacles and tidy up the roadbed, and the safety of construction workers can be protected by mechanical equipment.

[0065] Step 3: Set anchor rods 7 evenly on the subgrade where the rectangular frame main body 1 needs to be installed;

[0066] Step 4 Install the section length of the rectangular frame main body 1 according to the needs, determine the setting quantity of the rectangular frame main body 1, then lay the rectangular frame main body 1 on the roadbed, and connect the adjacent rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com