Phase change thermo-regulation fiber containing ionic liquid and preparation method of phase change thermo-regulation fiber

A technology of ionic liquid and temperature-regulating fiber, which is applied in fiber treatment, chemical instruments and methods, heat exchange materials, etc., can solve the problems of easy phase change separation, strong corrosion, high supercooling phenomenon, etc., and achieve acidity and alkalinity Controllable, good thermal stability, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

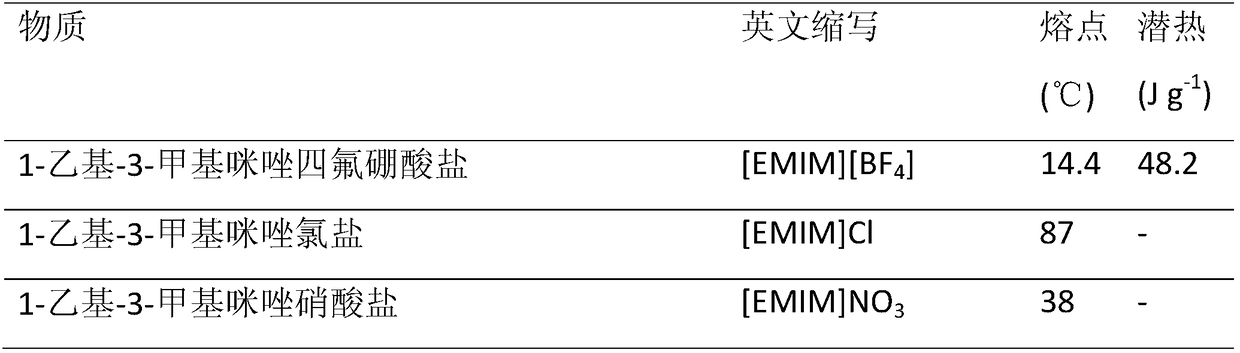

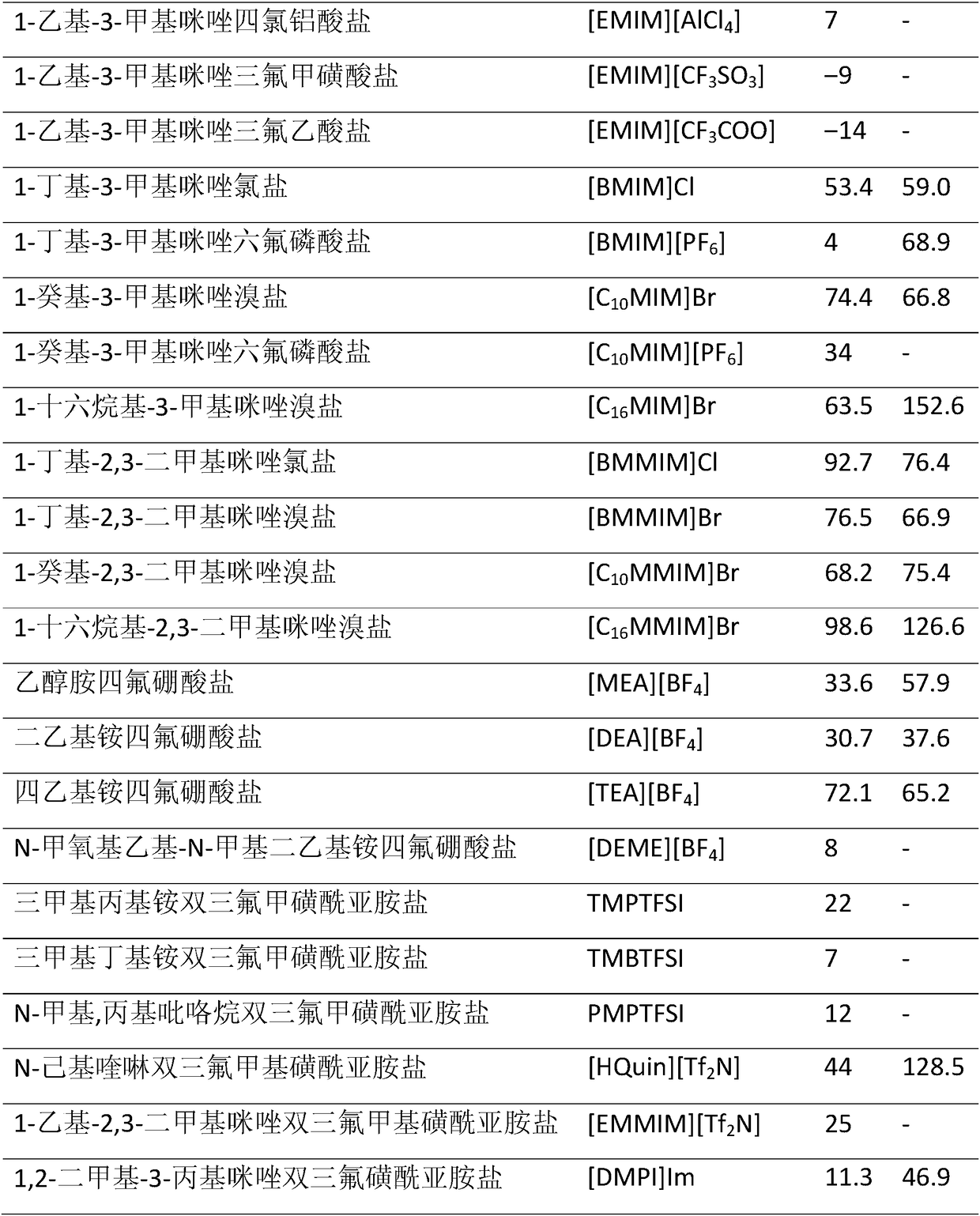

[0038] (1) Add 50g of [EMIM][BF 4 ], 2g of kaolin, and 5g of aluminum nitride were placed in a beaker and stirred and mixed, and then heated to 50°C for 40 minutes of ultrasonic vibration under the condition of ultrasonic frequency 30-50Hz, and then kept under vacuum at 50°C for 12h to obtain the core The layer material is spare.

[0039] (2) Use a screw extruder to melt polypropylene, and meter it to the spinneret assembly. The core layer material is metered and injected into the spinneret assembly by a rotary vane screw, and the fusion of the two is realized at the extrusion spinneret. Through skin-core compounding Spinning to obtain the functional precursors with the phase change material containing ionic liquid as the core layer and the fiber-forming polymer as the skin layer, wherein the spinning temperature is 240°C, the spinning speed is 600m / min, and then the functional precursors are drawn. The drawing temperature is 80° C., and the drawing ratio is 1.5 times to obta...

Embodiment 2

[0041] (1) Add 50g of [EMIM][BF 4 ], 2g of kaolin, and 5g of graphite powder were placed in a beaker and stirred and mixed, and then heated to 50°C for 40 minutes under the condition of an ultrasonic frequency of 30-50 Hz, and then subjected to ultrasonic oscillation for 40 minutes, and then kept under a vacuum of 50°C for 12 hours to obtain a core layer Material spare.

[0042] (2) Use a screw extruder to melt polypropylene, and meter it to the spinneret assembly. The core layer material is metered and injected into the spinneret assembly by a rotary vane screw, and the fusion of the two is realized at the extrusion spinneret. Through skin-core compounding Spinning to obtain the functional precursors with the phase change material containing ionic liquid as the core layer and the fiber-forming polymer as the skin layer, wherein the spinning temperature is 240°C, the spinning speed is 600m / min, and then the functional precursors are drawn. The drawing temperature is 80° C., a...

Embodiment 3

[0044] (1) Add 50g of [EMIM][BF 4], 2g of calcium oxide, and 5g of aluminum nitride were placed in a beaker and stirred and mixed, and then heated up to 50°C for 40 minutes under the condition of ultrasonic frequency of 30-50Hz, and then ultrasonically oscillated for 40min, and then kept under vacuum at 50°C for 12h to obtain the core The layer material is spare.

[0045] (2) A screw extruder is used to melt polypropylene, and it is metered and delivered to the spinneret assembly. The core layer material is metered and injected into the spinneret assembly by a rotary vane screw, and the confluence of the two is realized at the extrusion spinneret, through skin-core compounding Spinning to obtain a functional precursor with the phase change material containing the ionic liquid as the core layer and the fiber-forming polymer as the skin layer, wherein the spinning temperature is 240°C, the spinning speed is 600m / min, and then the functional precursor is drawn. The drawing tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com