Method for treating tin-copper slag through whole wet method

An all-wet, tin-copper technology, applied in the field of tin refining and copper slag removal, can solve the problems of poor economic benefit, long process flow, low softening point of tin-copper slag, etc., and achieve the effects of reduced production cost and simple and feasible process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for treating tin-copper slag by an all-wet method, the method steps are as follows:

[0022] (1) 500g of tin-copper slag containing 10.2% copper and 50.6% tin is leached under pressure with sodium hydroxide, leaching conditions: initial alkalinity of sodium hydroxide 100g / l, liquid-solid mass ratio 6:1, reaction temperature 120~130°C, oxygen flow during the reaction process, the pressure of the kettle is 1MPa, and the reaction time is 4 hours to obtain 2.85L sodium stannate solution containing Sn76.49g / l and Cu3.57g / l and 170g containing Sn20.58%, Cu24. 01% leaching residue.

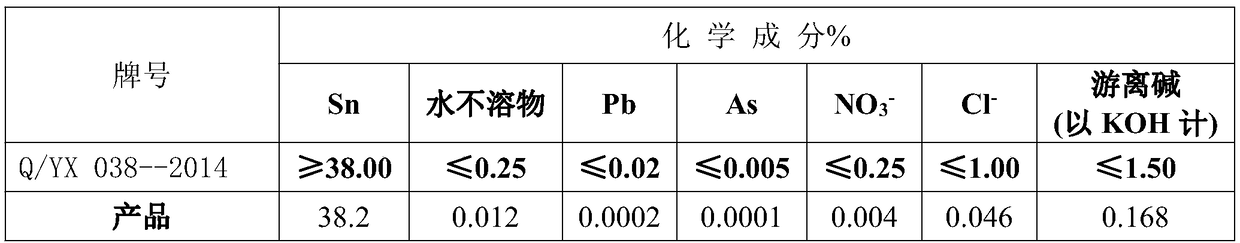

[0023] (2) the sodium stannate solution in the above-mentioned steps (1) is through adding tin to remove antimony copper, adding sodium sulfide to remove lead and then evaporating and concentrating, cooling and crystallizing to obtain sodium stannate product 382g, and product quality is as follows.

[0024] Table 1 Sodium stannate product quality Unit: %

[0025]

[0026] (3) After w...

Embodiment 2

[0029] A method for treating tin-copper slag by an all-wet method, the method steps are as follows:

[0030] (1) 500g of tin-copper slag containing 20.6% of copper and 65% of tin is leached with sodium hydroxide under pressure, leaching conditions: initial alkalinity of sodium hydroxide 200g / l, liquid-solid mass ratio 7:1, reaction temperature 140~150°C, oxygen flow during the reaction process, the pressure of the kettle is 1.6MPa, and the reaction time is 2 hours to obtain 3.2L sodium stannate solution containing Sn95.94g / l, Cu3.24g / l and 145g containing Sn12.41%, Cu63 .44% leach residue.

[0031] (2) the sodium stannate solution in the above-mentioned steps (1) is through adding tin to remove antimony copper, adding sodium sulfide to remove lead and then evaporating and concentrating, cooling and crystallizing to obtain sodium stannate product 582g, and product quality is as follows.

[0032] Table 1 Sodium stannate product quality Unit: %

[0033]

[0034] (3) After wa...

Embodiment 3

[0037] A method for treating tin-copper slag by an all-wet method, the method steps are as follows:

[0038] (1) 500g of tin-copper slag containing 10.2% copper and 79.9% tin is leached under pressure with potassium hydroxide, leaching conditions: initial alkalinity of potassium hydroxide 60g / l, liquid-solid mass ratio 12:1, reaction temperature 110~120°C, oxygen flow during the reaction process, the pressure of the kettle is 2MPa, and the reaction time is 6 hours to obtain 2.78L potassium stannate solution containing Sn79.50g / l, Cu3.21g / l and 165g leaching residue containing Sn19.40%, Cu25.50%.

[0039] (2) Potassium stannate product 424g is obtained after adding tin and removing antimony copper in the above-mentioned steps (1), adding sodium sulfide to remove lead, and obtaining potassium stannate product 424g after crystallization by cooling.

[0040] Table 1 Potassium stannate product quality Unit: %

[0041]

[0042] (3) After washing the leaching residue of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com