Treatment technology suitable for high ammonia nitrogen dispersed domestic sewage

A domestic sewage and treatment process technology, applied in the direction of biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult cultivation of nitrifying bacteria, large footprint, and nitrification Weak capacity and other problems, to achieve the effect of facilitating attachment growth, strengthening ammonia nitrogen nitrification and decarburization ability, and facilitating attachment growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

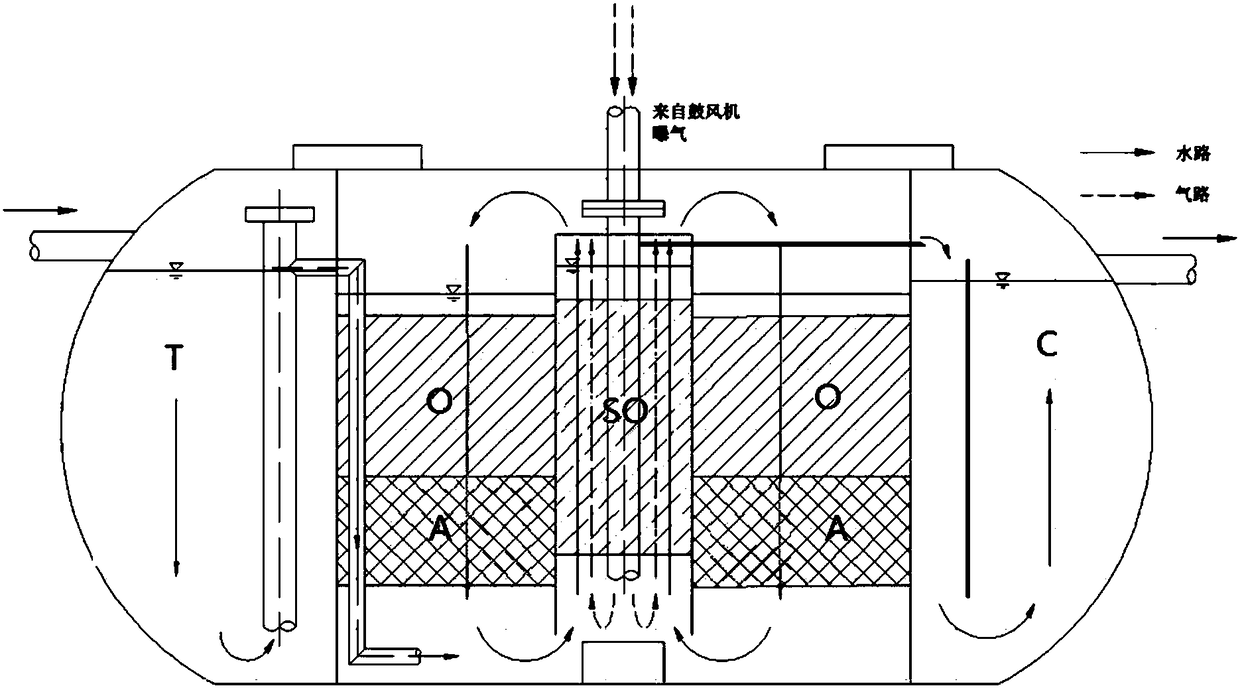

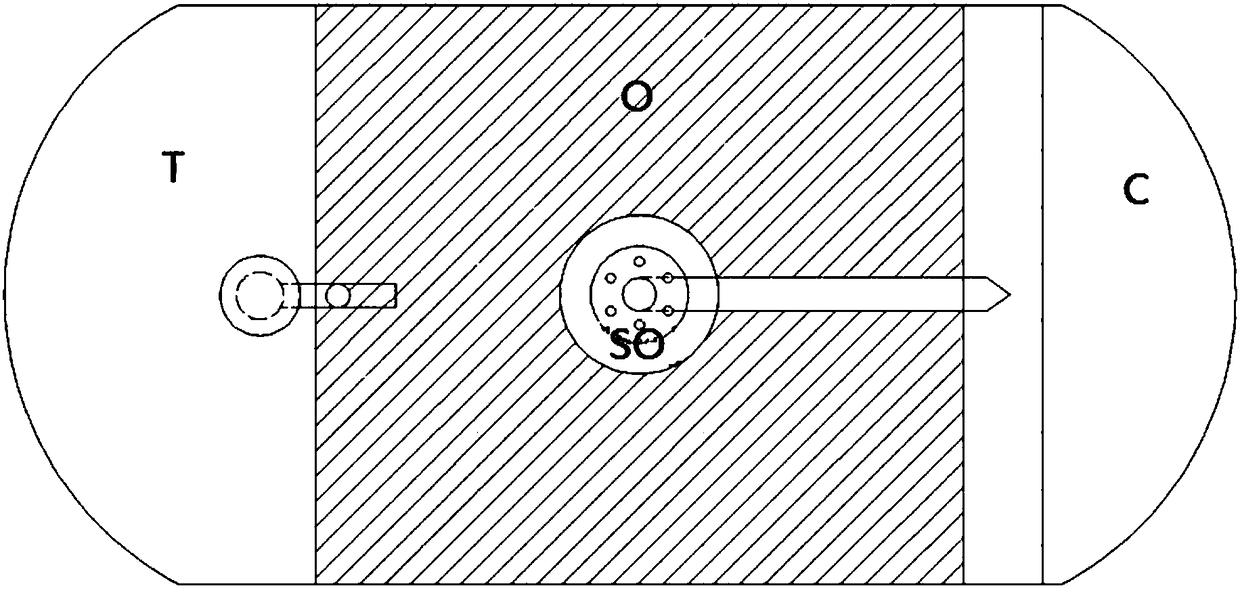

[0034] A new process for the treatment of high-ammonia-nitrogen dispersed domestic sewage, which can be used as Figure 1-2 The integrated processing equipment is realized, and the steps are as follows:

[0035] 1. According to the technological process of the invention, the integrated treatment equipment is sequentially divided into five areas, including the homogeneous adjustment area T for adjusting water quality and quantity, the aerobic decarbonization area O for removing organic matter in sewage, and the area for denitrification Anoxic denitrification zone A, superoxide nitrification zone SO for removing ammonia nitrogen, and precipitation zone C for removing suspended solids.

[0036] 2. Install linear elastic three-dimensional fillers in the aerobic decarburization zone O and anoxic denitrification zone A, wherein the aerobic decarburization zone O is composed of linear elastic three-dimensional fillers with a unit diameter of Φ150mm and a spacing of 50mm In contact w...

Embodiment 2

[0039] Treatment of a high ammonia nitrogen dispersed domestic sewage

[0040] 1. Fill the honeycomb ceramic filler with 1.0% iron doping mass fraction into the superoxide reaction zone SO of the equipment.

[0041] 2. The scattered domestic sewage in a certain rural area is passed into the integrated treatment equipment in Example 1, and the influent flow rate is 2m 3 / d, the average water quality of the measured sewage is: COD=164mg / L, TN=148mg / L, NH 3 - N = 107 mg / L, TP = 9.5 mg / L. The COD / TN ratio of sewage is about 1, and the ammonia nitrogen concentration accounts for 72.4% of the total nitrogen concentration.

[0042] 3. Adjust the aeration volume of the blower so that the gas-water flow ratio in the SO in the superoxide nitrification zone is 3:1.

[0043] Processing effect:

[0044] After the above system is stable, take out the water for testing. The same process parameters were used to treat the same sewage by contact oxidation as a comparative experiment. The ...

Embodiment 3

[0048] Treatment of public toilet sewage in a tourist attraction

[0049] 1. Fill the honeycomb ceramic filler with 5.0% iron doping mass fraction into the superoxide reaction zone SO of the equipment.

[0050] 2. The domestic sewage of a public toilet in a tourist attraction is passed into the integrated decentralized domestic sewage treatment equipment in Example 1, and the influent flow rate is 2m 3 / d, the average water quality of the measured sewage is: COD=196.4mg / L, TN=102mg / L, NH 3 - N = 96.8 mg / L, TP = 12.68 mg / L. The COD / TN ratio of sewage is about 2, and the ammonia nitrogen concentration accounts for 94.9% of the total nitrogen concentration.

[0051] 3. Adjust the aeration rate of the blower so that the gas-water flow ratio in the SO in the superoxide nitrification zone is 4:1.

[0052] Processing effect:

[0053] After the above system is stable, take out the water for testing. The initial concentration and removal effect of pollutants in water are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| dissolved oxygen | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com