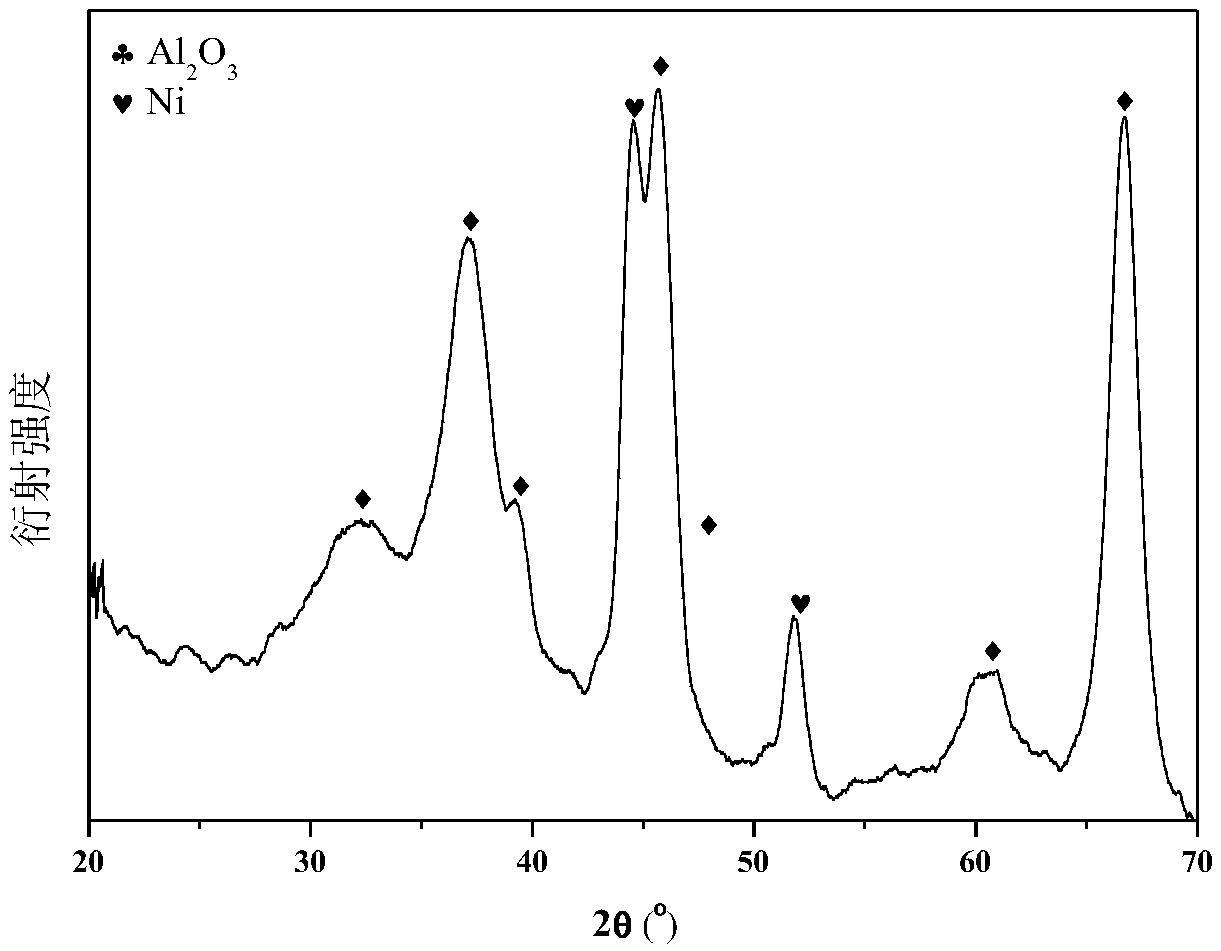

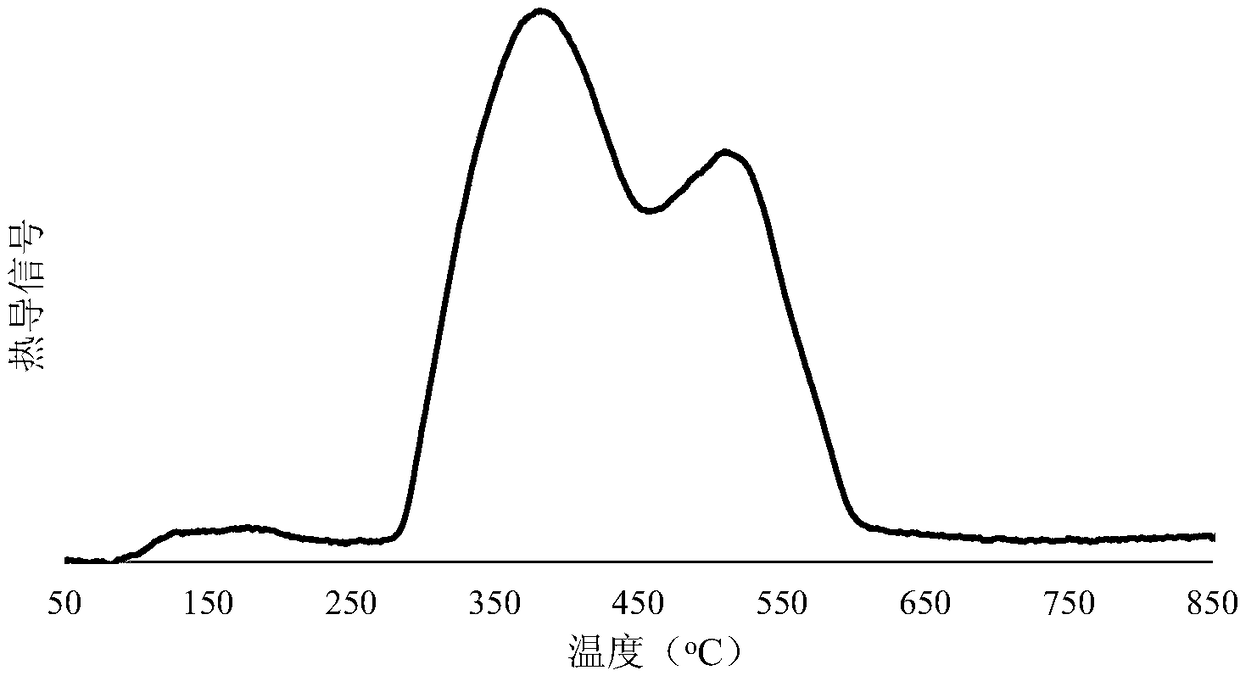

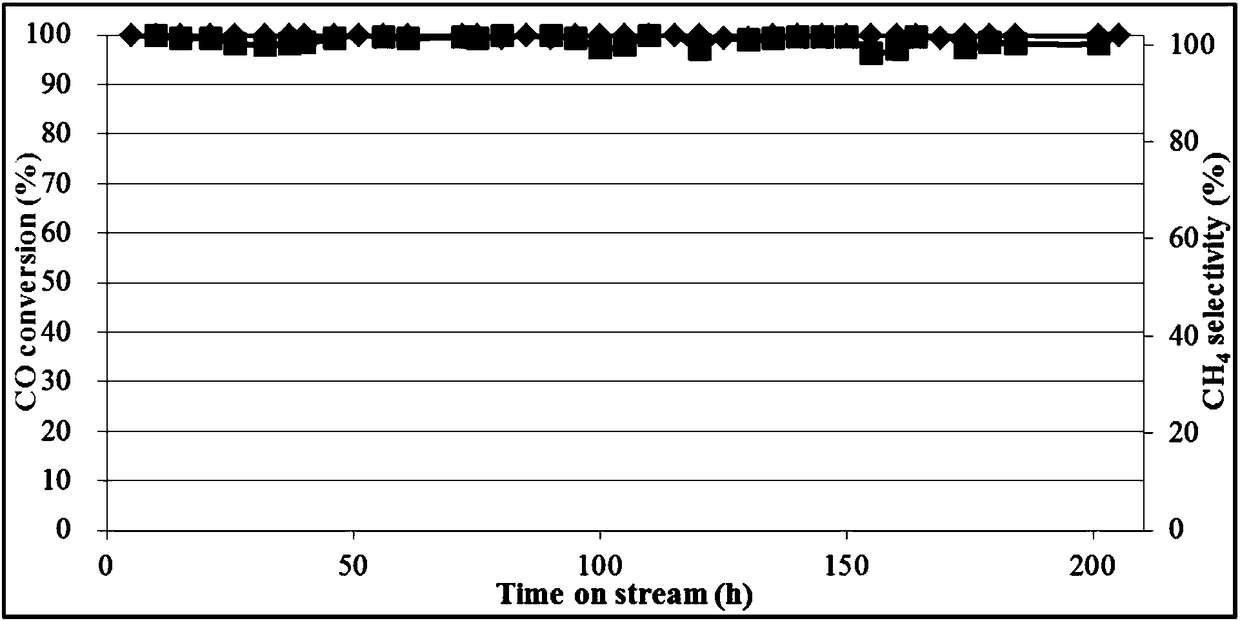

Methanation catalyst as well as preparation method and application thereof

A methanation catalyst and catalyst technology, which can be used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as huge patent royalties, avoid flying hot sintering, have strong raw material processing capacity, Promotes the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of catalyst carrier

[0038] Weigh 200g of aluminum isopropoxide and pour it into 120g of isopropanol and stir to dissolve; weigh 127.2g of PVP, 0.84g of potassium nitrate and 1.38g of lanthanum nitrate and pour it into 3600g of deionized water and stir to dissolve. The temperature of the deionized aqueous solution is maintained at 85°C; The isopropanol solution was slowly added dropwise to the deionized water solution under vigorous stirring and continued to stir for 2 hours. Then add 3.9mol nitric acid and stir to dissolve until the hydrolysis is complete. Finally, the excess solvent was evaporated, so that the solid content in the solvent was 30%, and then spray molding was carried out. The shaped powder was collected and dried at 120°C for 3 hours, and the dried sample was put into a muffle furnace and calcined at 1000°C for 3 hours to obtain a microsphere powder carrier. The specific surface area measured by isothermal nitrogen adsorption method i...

Embodiment 2

[0046] (1) Preparation of catalyst carrier

[0047] Weigh 200g of aluminum isopropoxide and pour it into 180g of isopropanol and stir to dissolve; weigh 101.7g of PVP, 1.12g of potassium nitrate and 0.69g of lanthanum nitrate and pour it into 4000g of deionized water and stir to dissolve. The temperature of the deionized aqueous solution is maintained at 75°C; The isopropanol solution was slowly added dropwise to the deionized water solution under vigorous stirring and continued to stir for 3 hours. Then add 4.88mol nitric acid and stir to dissolve until the hydrolysis is complete. Finally, the excess solvent was evaporated, so that the solid content in the solvent was 35%, and then spray molding was carried out. The shaped powder was collected and dried at 120° C. for 3 hours, and the dried sample was put into a muffle furnace and calcined at 1100° C. for 3 hours to obtain a microsphere powder carrier. The specific surface area measured by isothermal nitrogen adsorption met...

Embodiment 3

[0053] (1) Preparation of catalyst carrier

[0054] Weigh 200g of aluminum isopropoxide and pour it into 96g of isopropanol and stir to dissolve; weigh 190.8g of PVP, 0.62g of potassium nitrate and 1.73g of lanthanum nitrate and pour it into 2800g of deionized water and stir to dissolve. The temperature of the deionized aqueous solution is maintained at 95°C; The isopropanol solution was slowly added dropwise to the deionized water solution under vigorous stirring and continued to stir for 2 hours. Then add 2.93mol nitric acid and stir to dissolve until the hydrolysis is complete. Finally, the excess solvent was evaporated, so that the solid content in the solvent was 25%, and then spray molding was carried out. The shaped powder was collected and dried at 120° C. for 2 hours, and the dried sample was put into a muffle furnace and calcined at 960° C. for 3 hours to obtain a microsphere powder carrier. The specific surface area measured by isothermal nitrogen adsorption metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com