Preparation method of emulsion having whitening and moisturizing effects

A whitening and efficacy technology, applied in the direction of medical preparations containing active ingredients, skin care preparations, pharmaceutical formulas, etc., can solve the problems of single whitening mechanism, grainy feeling, and incomplete dissolution of active ingredients, so as to increase the whitening effect , stable emulsion, good emulsification and moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

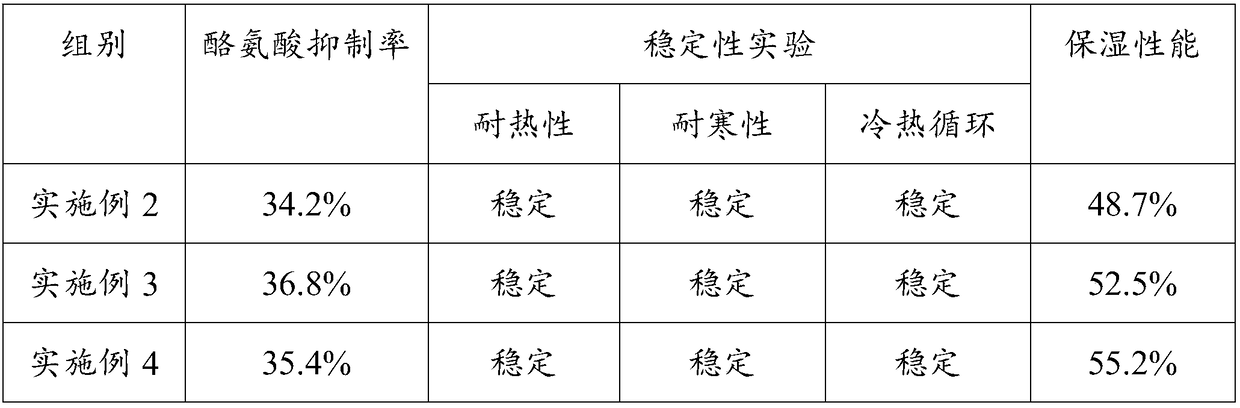

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of seaweed polysaccharide enzymatic hydrolysis product

[0029] 1. Seaweed polysaccharide extraction method: wash the seaweed, control the water, dry it in an oven at 60°C, and crush it. Take 1kg of algae powder, add 2L of 95% ethanol solution to soak and degrease, and let stand overnight. Take the degreased algae powder, add distilled water according to 1kg:10L solid-liquid ratio, and bathe in 95℃ water for 2h. After hot water extraction, cool and stand for 1 hour, then refrigerate and centrifuge for 10 minutes (10000 rpm, 4°C). The supernatant, that is, the crude polysaccharide extract was concentrated to 2 L by rotary evaporation, and 95% ethanol solution was added until the final volume fraction of ethanol was 30%, and stood overnight. The sample solution was refrigerated and centrifuged for 10 minutes (10,000 rpm, temperature 4°C), and the precipitate was taken, and a small amount of distilled water was added to dissolve the precipitate ...

Embodiment 2

[0032] (1) Weigh 20 g of hydrogenated soybean oil (purchased from Wuhan Hezhong Biochemical Manufacturing Co., Ltd.), and heat to 85° C. to obtain liquid oil phase I;

[0033](2) 4g of arbutin (purchased from Xi'an Lutian Biotechnology Co., Ltd.), 6g of ascorbyl glucoside (purchased from Xi'an Wanfang Biotechnology Co., Ltd.), nicotinamide were weighed in a ratio of 4:6:1 by mass (purchased from Henan Datang Chemical Co., Ltd.) 1g, the above-mentioned three kinds of substances are mixed to obtain a composite whitening active substance;

[0034] (3) composite whitening active substance by mass ratio: liquid oil phase I=0.30: 1, take by weighing composite whitening active substance 6g and add in the liquid oil phase I of step (1) gained, mix homogeneously, obtain liquid oil phase II;

[0035] (4) weigh 30g of seaweed polysaccharide enzymolysis product, 15g of phospholipids and 150g of distilled water in a ratio of 0.2:0.1:1 by mass, heat to 75-85°C, and mix to obtain a liquid wa...

Embodiment 3

[0038] (1) 15 g of hydrogenated soybean oil (purchased from Wuhan Hezhong Biochemical Manufacturing Co., Ltd.) was weighed, heated to 85° C. to obtain liquid oil phase I;

[0039] (2) 1 g of arbutin (purchased from Xi'an Lvtian Biotechnology Co., Ltd.), 1.5 g of ascorbyl glucoside (purchased from Xi'an Wanfang Biotechnology Co., Ltd.), Amide (purchased from Henan Datang Chemical Co., Ltd.) 0.5g, the above three substances were mixed to obtain a composite whitening active substance;

[0040] (3) by mass ratio composite whitening active substance: liquid oil phase I=0.15: 1 take by weighing composite whitening active substance 2.25g and add in the liquid oil phase I of step (1) gained, mix homogeneously, obtain liquid oil phase II;

[0041] (4) weigh 12g of seaweed polysaccharide enzymolysis product, 7.5g of phospholipid and 150g of distilled water in a ratio of 0.08:0.05:1 by mass, heat to 75~85°C, and mix to obtain a liquid water phase;

[0042] (5) weigh 15 g of liquid oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com