Aluminum alloy plate for bus bars, which has excellent laser weldability

A laser welding, aluminum alloy plate technology, applied in conductive connection, small-sized batteries/batteries, batteries, etc., can solve the problems of shallow penetration depth, lack of joint strength, cracks, etc., and achieve excellent bending workability , The effect of excellent laser weldability and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

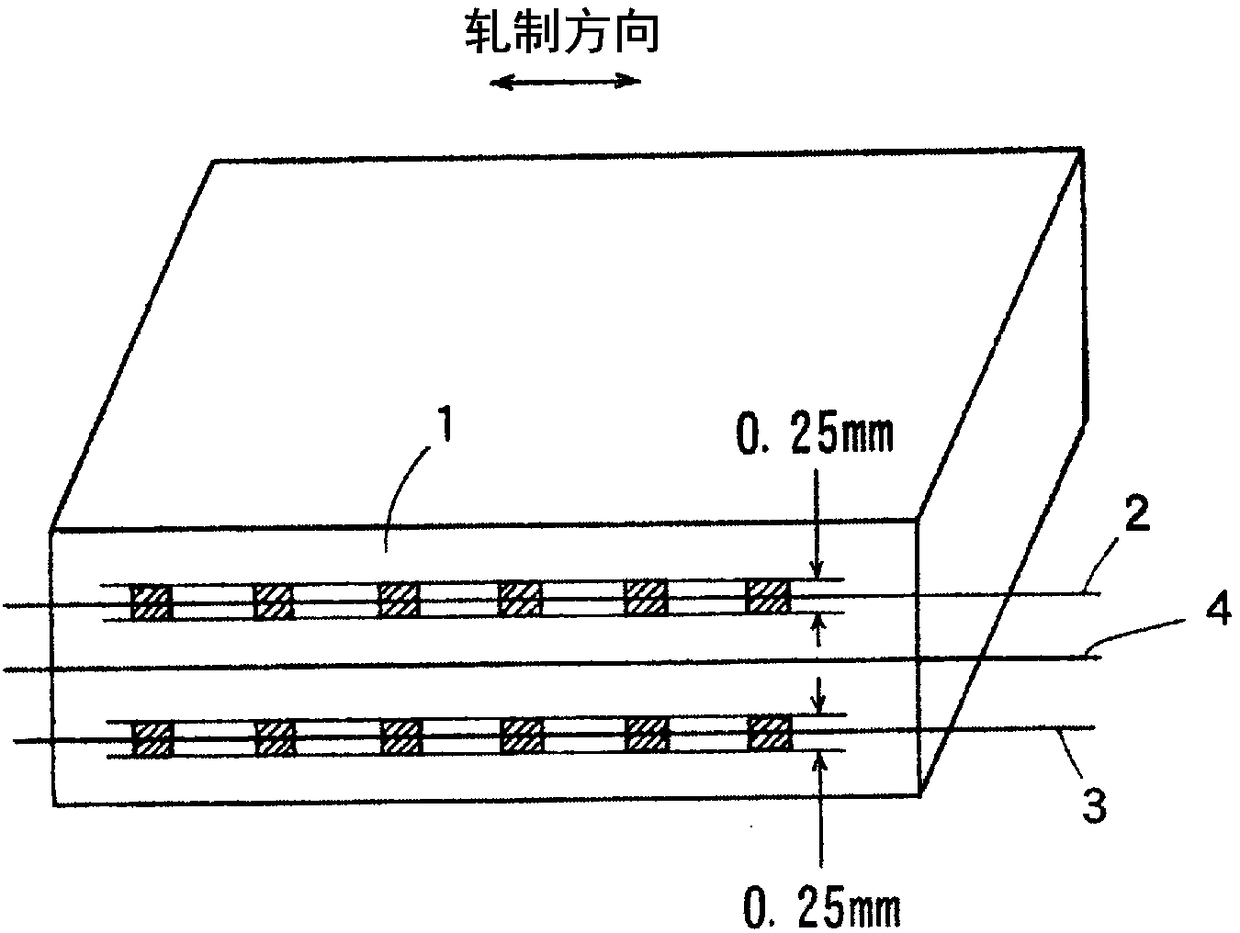

Image

Examples

Embodiment 1

[0040] Hereinafter, examples in which the effects of the present invention were confirmed are compared with comparative examples that do not satisfy the requirements of the present invention, and are specifically described. In addition, this invention is not limited to this Example.

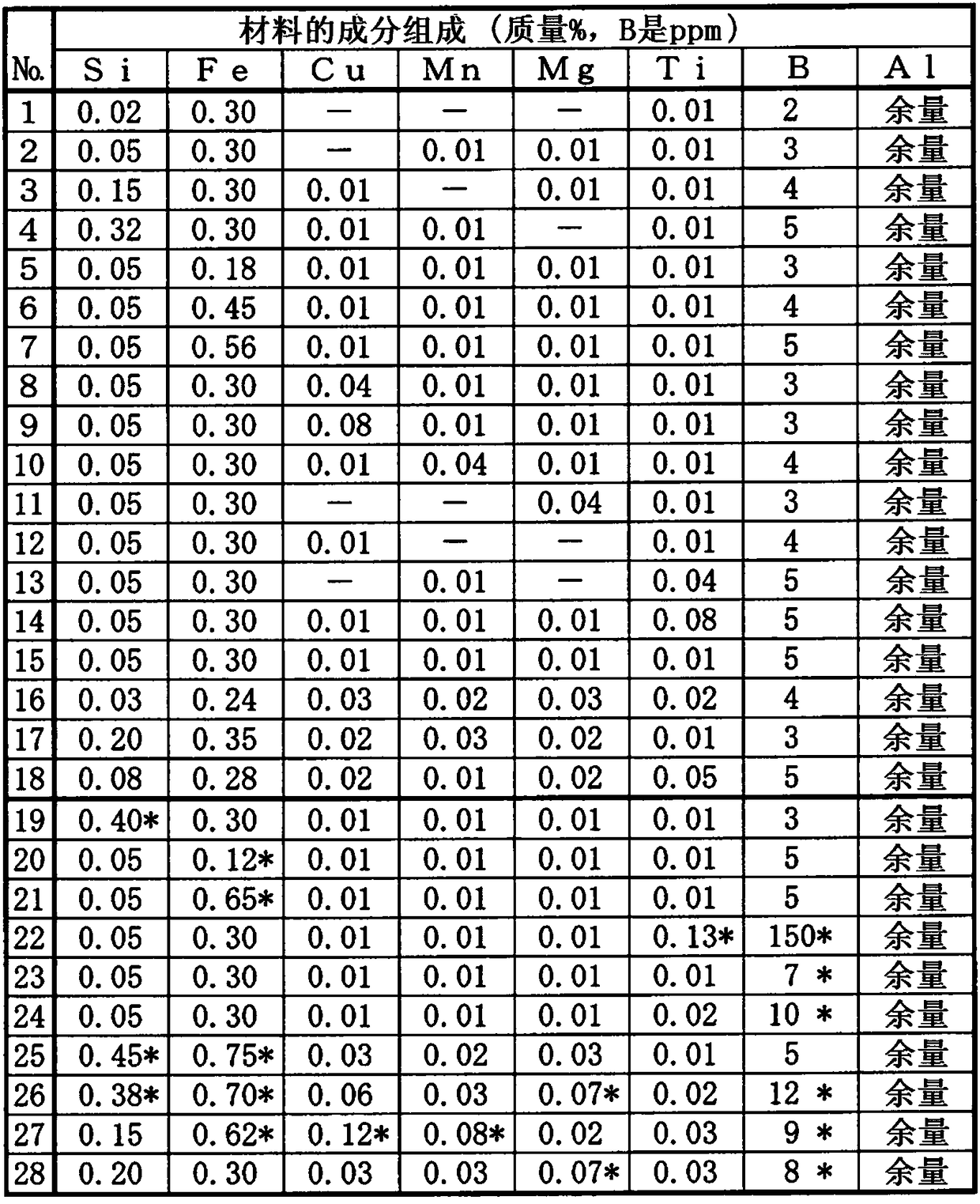

[0041] Aluminum alloys (Nos. 1 to 28) having the compositions shown in Table 1 were melted and cast to produce ingot slabs, and face cutting was performed. The cooling rate during casting was 0.4°C / sec. This slab was subjected to a homogenization treatment at 570° C., and then hot-rolled to obtain a hot-rolled sheet having a thickness of 5 mm. Thereafter, cold rolling was implemented to produce a cold-rolled sheet having a thickness of 2 mm. This cold-rolled sheet was further annealed at 350°C to be an O material (annealed material) of the aluminum alloy sheet.

[0042] 【Table 1】

[0043]

[0044] *Deviating from the provisions of the present invention

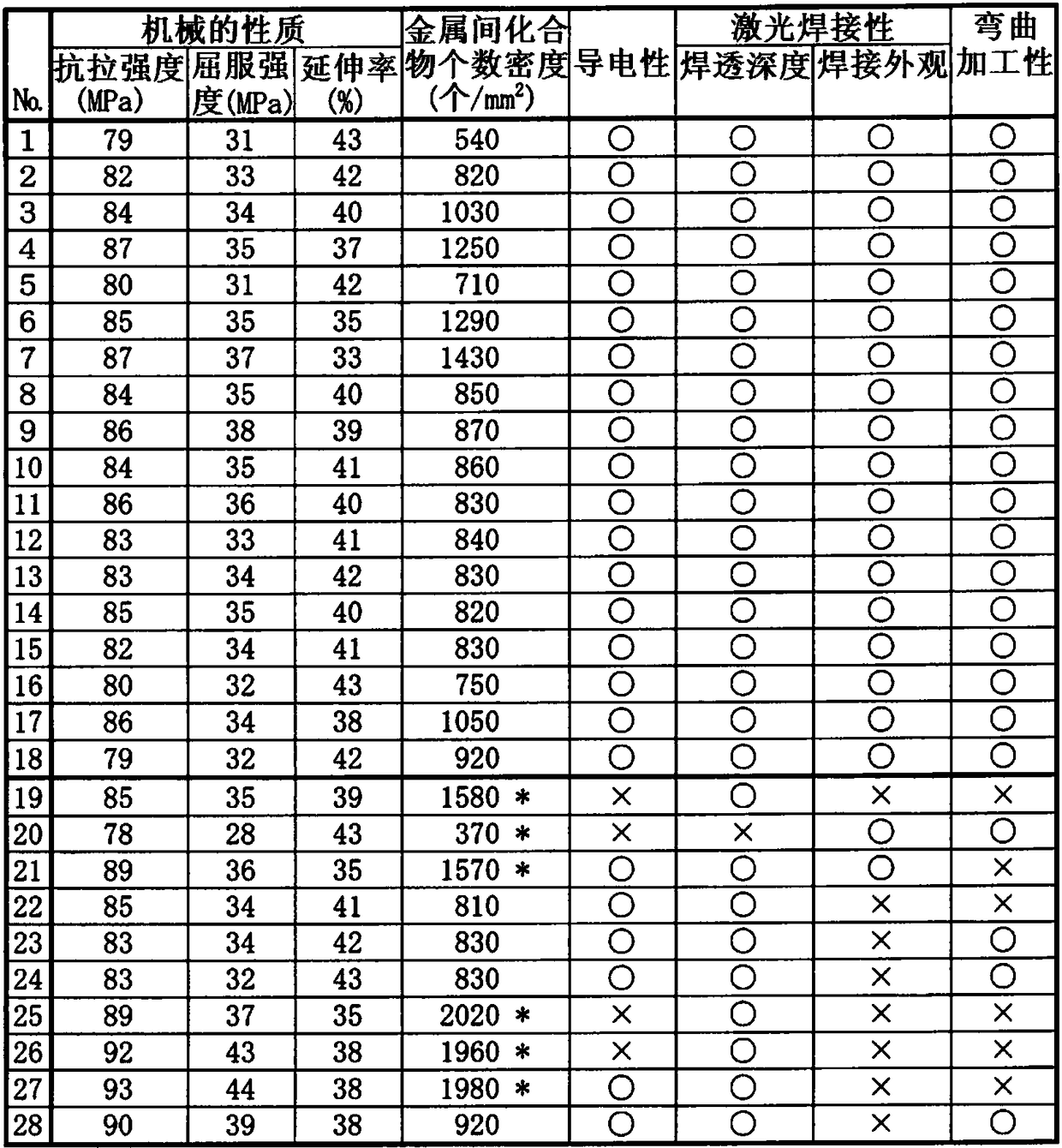

[0045] For each aluminum alloy pla...

Embodiment 2

[0068] An aluminum alloy having a composition of No. 2 in Table 1 was melted and cast at various cooling rates shown in Table 3 to produce ingot slabs. For this slab, a cold-rolled sheet with a thickness of 2 mm was produced under the same manufacturing process and conditions as in Example 1, and then annealed at 350° C. to obtain an O material (annealed material) of the aluminum alloy sheet.

[0069] For the aluminum alloy plates (No. 2-1 to 2-5) shown in Table 3, the number density, electrical conductivity, and bending workability of intermetallic compounds with a maximum length of 2 μm or more were measured in the same manner as in Example 1. . The results are shown in Table 3.

[0070] 【table 3】

[0071]

[0072] As shown in Table 3, No. 2-2 and No. 2-3 whose cooling rate was in the range of 0.1 to 1.0°C / sec during casting had the number density of intermetallic compounds within the range specified in the present invention, and were electrically conductive. Good prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com