Single-slip large-diameter drilling-grinding-free composite bridge plug and setting method thereof

A composite bridge plug, large-diameter technology, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc. operation and other problems, so as to avoid long construction period, high operation cost and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

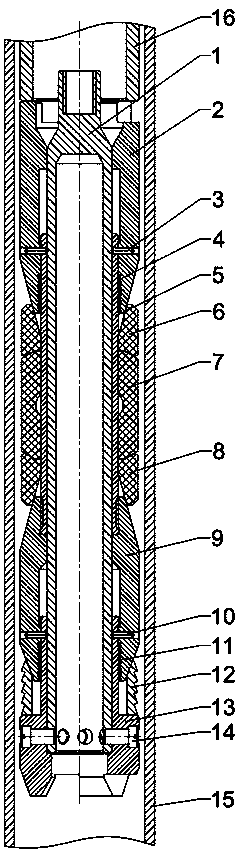

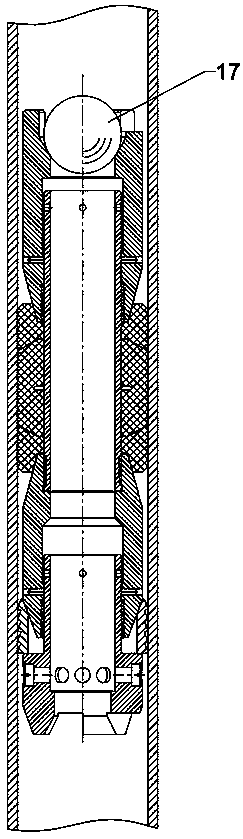

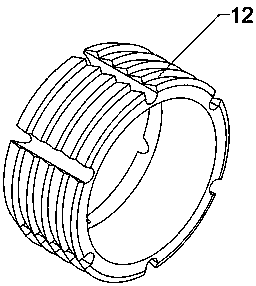

[0035] Embodiment 1: This embodiment provides a single-slip large-diameter composite bridge plug without drilling and grinding, such as figure 1 As shown, it includes setting rod 1, upper cone 2, center pipe 5, lower cone 9, one-way integral slip 12, guide toe cap 13 and rubber cartridge assembly, wherein setting rod 1 is a similar hollow rod One end of which is provided with evenly distributed holes in the circumferential direction and is fixed with the guide toe 13 by the hand pin 14, and the other end is provided with a connecting thread to be connected with the bridge plug setting tool, and one end of the upper cone 2 passes through the upper cone The body shear pin 3 is fixedly sleeved on the outside of one end of the central tube 5 and the inside is fitted with an upper ratchet ring 4; the end surface of the other end of the upper cone 2 is used to contact the setting push cylinder 16 in the setting tool , the setting push cylinder 16 transmits the extrusion force to oth...

Embodiment 2

[0050] Embodiment 2: A method for setting a large diameter composite bridge plug, the specific steps include:

[0051] Step 1: Fix the setting rod 1 with the guide toe cap 13 through the hand pin 14, connect the setting tool with the thread on one end of the setting rod 1, and align the end face of the setting push cylinder 16 on the setting tool with the upper The cone 2 is brought into contact with each other to realize the connection between the single-slip large-diameter composite bridge plug and the setting tool.

[0052] In step 2, the single-slip large-diameter composite bridge plug is lowered to a predetermined position in the casing through the cable or the coiled tubing.

[0053] Step 3: start the setting tool, the setting push cylinder 16 squeezes the end surface of the upper cone 2, when the extrusion force reaches the shear value of the upper cone shear pin 3, the pin is cut, and the upper cone 2 moves and squeezes The rubber cartridge assembly seals off the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com