A kind of preparation method of light color rosin resin

A rosin resin and light-colored technology, which is applied in the field of preparation of ultra-light-colored rosin resin, can solve problems such as difficult process control, high catalyst cost, and increased product cost, and achieve the goal of improving reusability, reducing color, and reducing odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

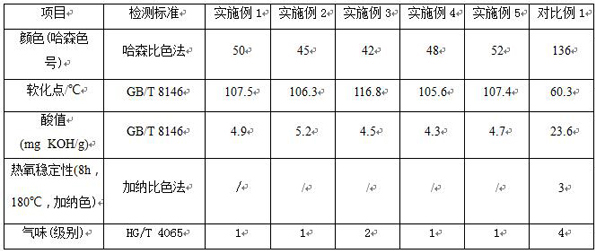

Examples

Embodiment 1

[0030] Ni / Al 2 o 3 Preparation of composite materials: take Ni(NO 3 ) 2 28 parts were added to absolute ethanol for ultrasonic dissolution, and then Al 2 o 3 Pour 25 parts of powder into Ni(NO 3 ) 2 In anhydrous ethanol, rotate and immerse in a rotary evaporator for 11h, remove the solvent, then vacuum dry at 76°C for 10h, and then put it in a muffle furnace and roast at 400°C for 2h to obtain Ni / Al 2 o 3 composite materials;

[0031] Montmorillonite / Ni / Al 2 o 3 Preparation of composite materials: Ni / Al 2 o 3 The composite material was dissolved in absolute ethanol and transferred to the reaction kettle, 9 parts of nitric acid was added dropwise to the reaction kettle, then 18 parts of distilled water was slowly added dropwise, stirred for 10 minutes, 35 parts of montmorillonite powder was added to the reaction kettle, and the reaction was stirred After 2 hours, let stand for 10.5 hours, then wash with water, dehydrate, vacuum dry, and then roast at 450°C for 2 hou...

Embodiment 2

[0037] Ni / Al 2 o 3 Preparation of composite materials: take Ni(NO 3 ) 2 20 parts were added to absolute ethanol for ultrasonic dissolution, and then Al 2 o 3 Pour 30 parts of powder into Ni(NO 3 ) 2 In absolute ethanol, rotate and immerse in a rotary evaporator for 10 hours, remove the solvent, then vacuum dry at 70°C for 11 hours, and then put it in a muffle furnace and roast at 500°C for 2 hours to obtain Ni / Al 2 o 3 composite materials;

[0038] Montmorillonite / Ni / Al 2 o 3 Preparation of composite materials: Ni / Al 2 o 3 The composite material was dissolved in absolute ethanol and transferred to the reaction kettle, 10 parts of nitric acid was added dropwise to the reaction kettle, and then 20 parts of distilled water was slowly added dropwise, stirred for 10 minutes, 32 parts of montmorillonite powder were added to the reaction kettle, stirred and reacted After 2 hours, let stand for 11 hours, then wash with water, dehydrate, vacuum dry, and then roast at 400°C ...

Embodiment 3

[0044] Ni / Al 2 o 3 Preparation of composite materials: take Ni(NO 3 ) 2 30 parts were added to absolute ethanol for ultrasonic dissolution, and then Al 2 o 3 Pour 28 parts of powder into Ni(NO 3 ) 2 In absolute ethanol, rotate and immerse in a rotary evaporator for 10.5h, remove the solvent, then vacuum dry at 73°C for 12h, and then put it into a muffle furnace and roast at 420°C for 2h to obtain Ni / Al 2 o 3 composite materials;

[0045] Montmorillonite / Ni / Al 2 o 3 Preparation of composite materials: Ni / Al 2 o 3 The composite material was dissolved in absolute ethanol and transferred to the reaction kettle, 8 parts of nitric acid was added dropwise to the reaction kettle, then 19 parts of distilled water was slowly added dropwise, stirred for 10 minutes, 30 parts of montmorillonite powder was added to the reaction kettle, stirred and reacted After 2 hours, let stand for 11.5 hours, then wash with water, dehydrate, vacuum dry, and then roast at 480°C for 2 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com