Photosensitive composition and use thereof

A photosensitive composition and compound technology, applied in optics, filters, optical elements, etc., can solve the problems of difficulty in producing high-quality display elements, unsatisfactory and other problems, and achieve improved display quality and reliability, The effect of high practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0174] Next, the present invention will be specifically described with reference to synthesis examples, reference examples, examples, and comparative examples, but the present invention is not limited by these examples. In addition, regarding the abbreviations of the additives in Tables 1 to 2, M-520 is Aronix M-520 (trade name; Toagosei Co., Ltd.), a compound having a polymerizable double bond, and NCI-930 is light Polymerization initiator Adeka ARKLS (ADEKA ARKLS) NCI-930 (trade name; Adeka (ADEKA) Co., Ltd.), VG3101L is epoxy compound Tecmo (TECHMORE) VG3101L (trade name; Printek (Printec) Co., Ltd.), EHPE3150 is an epoxy compound EHPE3150 (trade name; Daicel (Daicel) Co., Ltd.), TMA is an epoxy hardener trimellitic anhydride, and S510 is a coupling agent Sarah Ace (Sila -Ace) S510 (trade name; Jieen Zhi (JNC) Co., Ltd.), AO-60 is antioxidant Aidi Costapor (ADK STAB) AO-60 (trade name; Adeka (ADEKA) Co., Ltd.) , F-556 is the surfactant Megafac (Megafac) F-556 (trade name; ...

Synthetic example 1

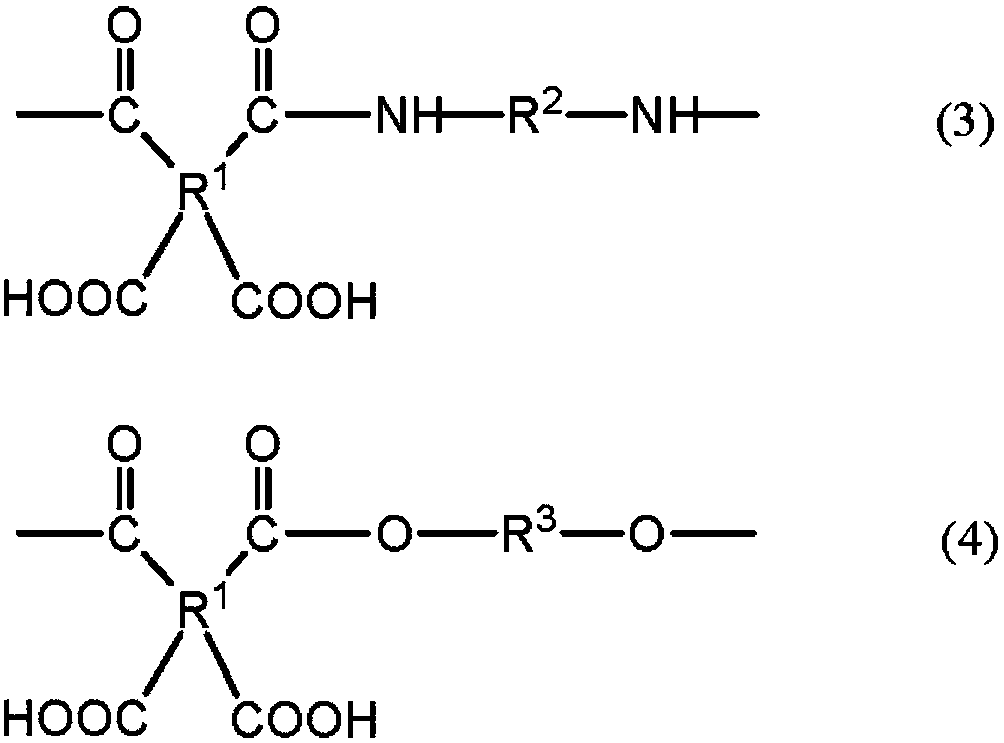

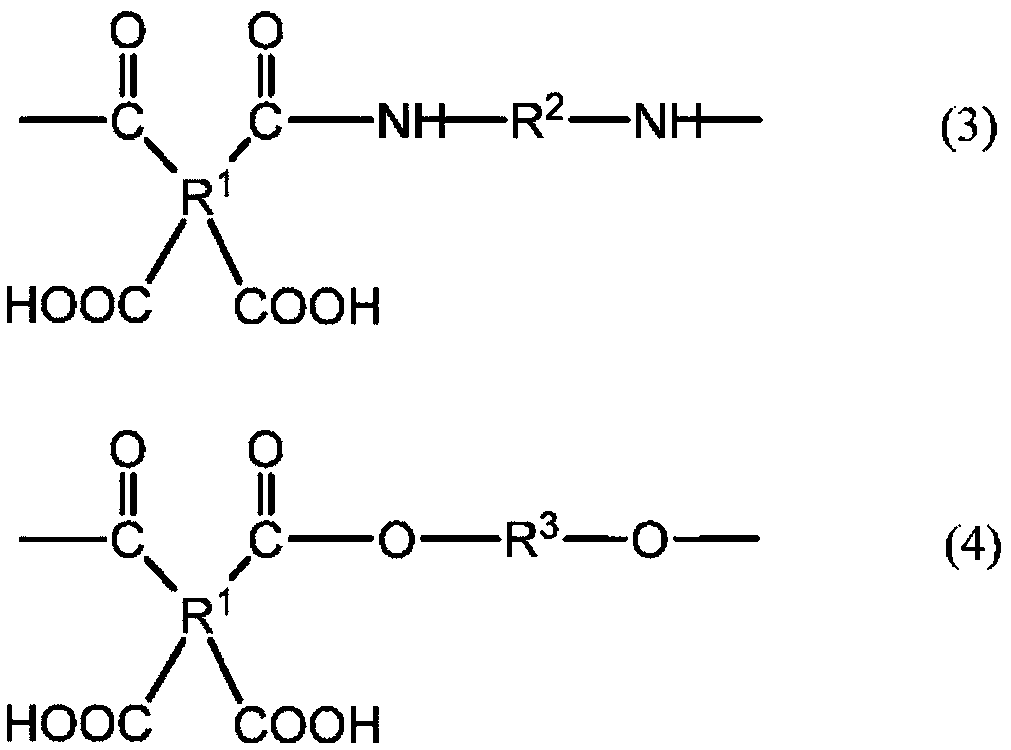

[0177] [Synthesis Example 1] Synthesis of Polyester Amic Acid (A) Solution

[0178] In a four-necked flask equipped with a stirrer, dehydrated and purified PGMEA, diethylene glycol ethyl methyl ether (hereinafter abbreviated as "EDM"), 4,4'-diphenyl Ether tetracarboxylic dianhydride (hereinafter abbreviated as "ODPA"), SMA1000P, 1,4-butanediol, and benzyl alcohol were stirred at 120° C. for 3 hours under a dry nitrogen stream.

[0179]

[0180] Thereafter, the reaction solution was cooled to 25°C, and 3,3'-diaminodiphenylsulfone (hereinafter abbreviated as "DDS") and EDM were added in the following weight, and stirred at 20°C to 30°C for 2 hours , and stirred at 120° C. for 2 hours.

[0181] DDS 12.72g

[0182] EDM 29.68g

[0183] [Z / Y=2.0, (Y+Z) / X=1.0]

[0184] The solution was cooled to room temperature to obtain a 30% by weight solution of a pale yellow transparent polyester amic acid (A). A part of the solution was sampled and the weight average molecular weight wa...

Synthetic example 2

[0185] [Synthesis Example 2] Synthesis of Epoxy Group-Containing Copolymer (B-1) Solution

[0186] In a four-necked flask with a stirrer, dehydrated and purified MMP as a polymerization solvent, glycidyl methacrylate as a radical polymerizable compound (a1) having an epoxy group, and Diethylene glycol dimethacrylate (NK ester 2G; trade name; Shin-Nakamura Chemical Industry Co., Ltd.) of other polymerizable compounds (a2), and then loaded with the following weight as the polymerization initiator Dimethyl-2 , 2′-azobis(2-methylpropionate) (V-601; trade name; Wako Pure Chemical Industries, Ltd.), and stirred at 110° C. for 2 hours under a stream of dry nitrogen.

[0187]

[0188] The solution was cooled to room temperature to obtain a 30.0% by weight solution of an epoxy group-containing copolymer (B-1). A part of the solution was sampled and the weight average molecular weight was determined by GPC analysis (polystyrene standard). As a result, the weight average molecular w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com