Damp-heat treatment technology for obtaining starch nanocrystal from native starch

A technology of starch nanocrystals and wet heat treatment, which is applied in the fields of starch processing, wet heat treatment and nanomaterials, can solve the problems that have not yet been unified, and have not yet been unified, and achieve the effect of promoting further industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] First, take 20g of absolutely dry commercially available waxy cornstarch in a 500ml vial with a screw cap, add 5.3ml of distilled water, store it overnight at 4°C, pass it through a 100-mesh sieve, and perform moist heat treatment. The conditions for moist heat treatment are: 96.3°C, the time is 2.43h. It was determined that after heat and humidity treatment, the starch crystallinity was 42.4%.

[0023] The wet-heated starch is fully dried in a blast drying oven at 40° C. to obtain waxy cornstarch after wet-heat treatment.

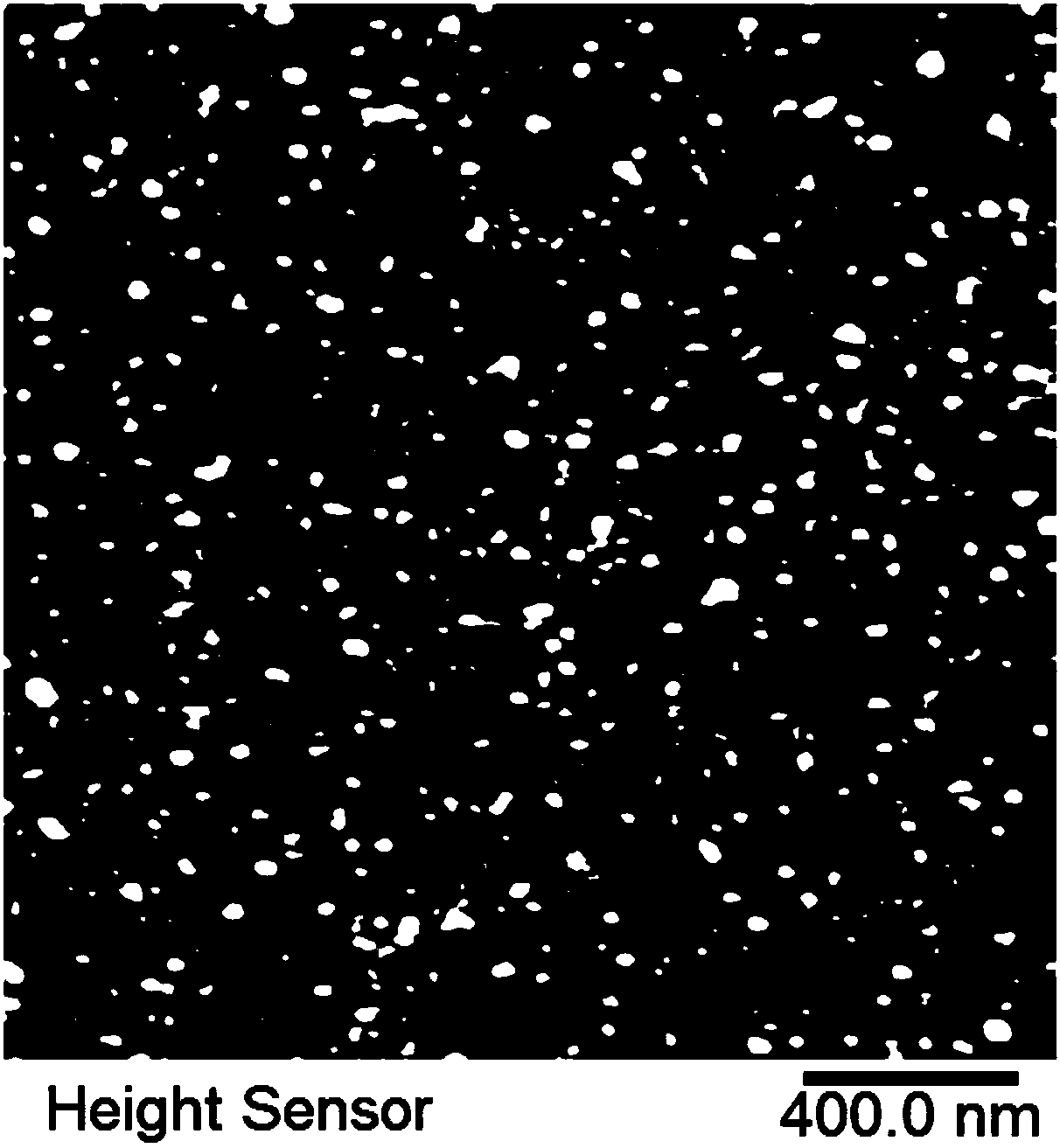

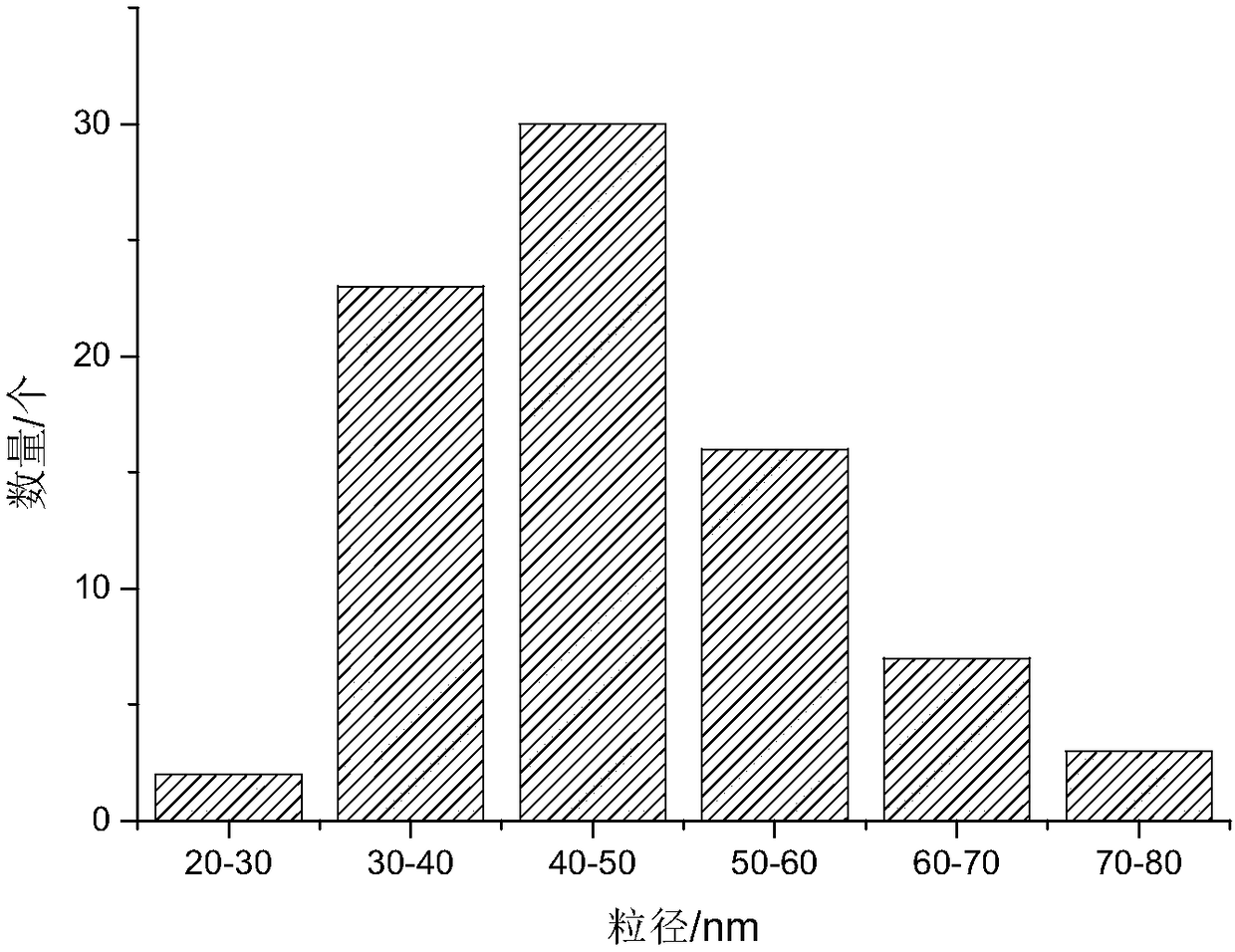

[0024] The starch obtained after the wet heat treatment was hydrolyzed with sulfuric acid, and after 4 days of hydrolysis, the obtained solution was centrifuged, the precipitate was washed until neutral, and the yield of starch nanocrystals reached 26.7% after freeze-drying. Characterization using atomic force microscopy, such as figure 1 shown. Image processing and statistical analysis were carried out to obtain a total of 81 starch nanocrystals...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com