Method and application for preparing titanium polysilicate flocculating agent by utilizing pickling waste liquor of cold-rolled titanium plates

A technology for pickling waste liquid and titanium polysilicate, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., and can solve the problems of poor flocculation effect of flocculants, difficult treatment, and toxicity. , to achieve the effect of high turbidity removal rate, lower preparation cost and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

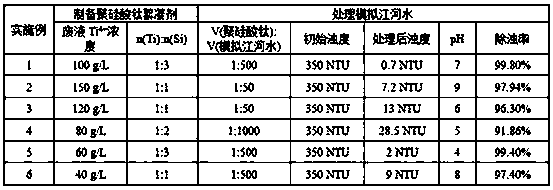

Embodiment 1

[0024] Embodiment 1: A kind of method that utilizes cold-rolled titanium plate pickling waste liquor to prepare polysilicate titanium flocculant, concrete steps are as follows:

[0025] (1) Na 2 SiO 3 Dissolved in deionized water to make Na 2 SiO 3 solution; where Na 2 SiO 3 The mass fraction of silicon dioxide in the solution is 5.35%;

[0026] (2) Add the stabilizer (the stabilizer is acetic acid) to the dilute sulfuric acid solution and mix evenly to obtain the stabilizer-sulfuric acid solution; the mass percentage concentration of the dilute sulfuric acid solution is 15.0%, and the stabilizer (acetic acid) in the stabilizer-sulfuric acid solution The mass percentage concentration is 3.3%;

[0027] (3) Add the stabilizer-sulfuric acid solution obtained in step (2) dropwise to the Na obtained in step (1) 2 SiO 3 Solution, activated at room temperature and a stirring speed of 400 r / min for 4 hours to obtain a polysilicic acid solution; wherein the stabilizer-sulfuric ...

Embodiment 2

[0032] Embodiment 2: A kind of method that utilizes cold-rolled titanium plate pickling waste liquor to prepare polysilicate titanium flocculant, concrete steps are as follows:

[0033] (1) Na 2 SiO 3 Dissolved in deionized water to make Na 2 SiO 3 solution; where Na 2 SiO 3 The mass fraction of silicon dioxide in the solution is 1.95%;

[0034] (2) Add the stabilizer (the stabilizer is acetic acid) to the dilute sulfuric acid solution and mix evenly to obtain the stabilizer-sulfuric acid solution; the mass percentage concentration of the dilute sulfuric acid solution is 30.0%, and the stabilizer (acetic acid) in the stabilizer-sulfuric acid solution The mass percentage concentration is 1.3%;

[0035] (3) Add the stabilizer-sulfuric acid solution obtained in step (2) dropwise to the Na obtained in step (1) 2 SiO 3 Solution, activated at room temperature and a stirring speed of 200 r / min for 1 h to obtain a polysilicate solution; wherein the stabilizer-sulfuric acid sol...

Embodiment 3

[0040] Embodiment 3: A kind of method that utilizes cold-rolled titanium plate pickling waste liquor to prepare polysilicate titanium flocculant, concrete steps are as follows:

[0041] (1) Na 2 SiO 3 Dissolved in deionized water to make Na 2 SiO 3 solution; where Na 2 SiO 3 The mass fraction of silicon dioxide in the solution is 3.95%;

[0042] (2) Add the stabilizer (the stabilizer is acetic acid) to the dilute sulfuric acid solution and mix evenly to obtain the stabilizer-sulfuric acid solution; the mass percentage concentration of the dilute sulfuric acid solution is 20.0%, and the stabilizer (acetic acid) in the stabilizer-sulfuric acid solution The mass percentage concentration is 4.6%;

[0043] (3) Add the stabilizer-sulfuric acid solution obtained in step (2) dropwise to the Na obtained in step (1) 2 SiO 3 solution, at room temperature, the stirring speed is 300 r / min under the conditions of activation reaction 2h to obtain polysilicic acid solution; wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com