Hydrocolloid and hydrocolloid dressing and preparation method thereof

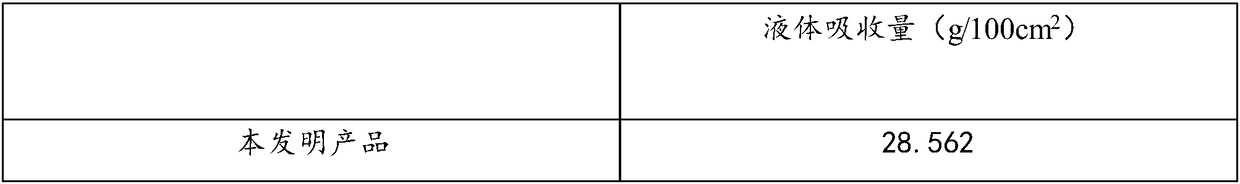

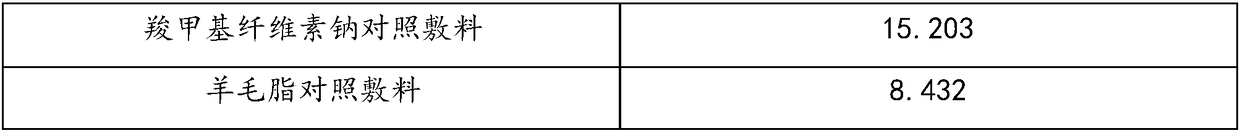

A hydrocolloid and liquid paraffin technology, applied in the field of medical materials, can solve the problems of not fast absorption, less than complete absorption, and peripheral skin damage, etc., achieve good moisturizing effect, strong ability to absorb exudate, and increase liquid absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

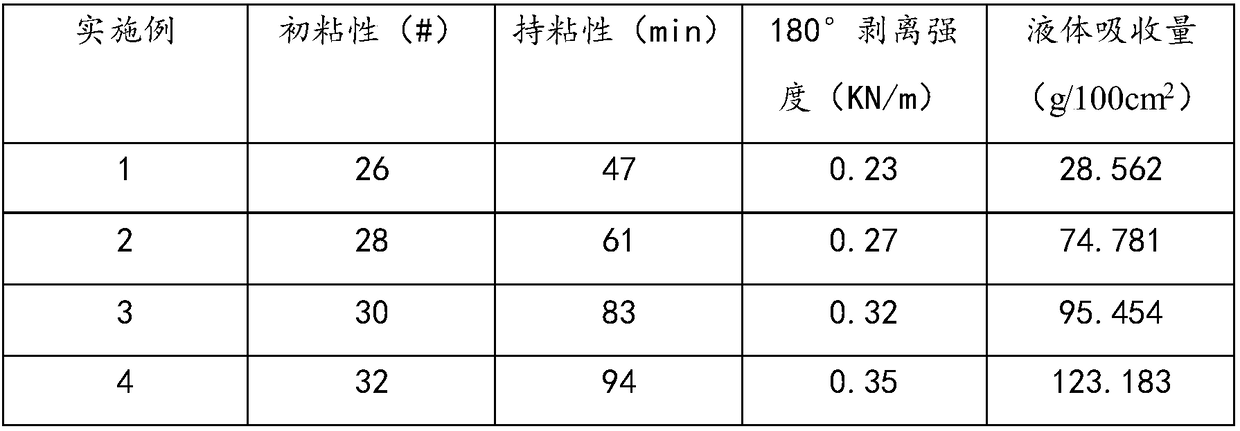

Examples

Embodiment 1

[0030] Embodiment 1: prepare described hydrocolloid and hydrocolloid dressing

[0031] 1. Preparation of hydrocolloids

[0032] Take 10 parts of high molecular weight copolymers of polystyrene block and polyethylene-butylene block and 10 parts of liquid paraffin in proportion by weight, and soften in a reaction kettle at a temperature of 200 ° C for 40 minutes;

[0033] Adjust the temperature, and after the temperature drops to 100°C, take 5 parts of lanolin, 20 parts of sodium carboxymethyl cellulose, and 5 parts of sodium hyaluronate according to the weight ratio, and put them into the softened polystyrene block and polyethylene -In the high molecular weight copolymer of butene block, mix 20min with the rotating speed of 80r / min, make it mix to form the homogeneous molten substance, then vacuum defoaming, obtain hydrocolloid;

[0034] 2. Preparation of hydrocolloid dressing

[0035] Transfer the hydrocolloid after vacuum defoaming to the glue tank in the hot-melt adhesive ...

Embodiment 2

[0036] Embodiment 2: prepare described hydrocolloid and hydrocolloid dressing

[0037] 1. Preparation of hydrocolloids

[0038] Take 20 parts of high molecular weight copolymers of polystyrene block and polyethylene-propylene block and 10 parts of liquid paraffin in proportion by weight, and soften in a reaction kettle at a temperature of 200° C. for 40 minutes;

[0039] Adjust the temperature, and after the temperature drops to 150°C, take 5 parts of lanolin, 30 parts of sodium carboxymethyl cellulose, and 5 parts of sodium hyaluronate according to the weight ratio, and put them into the softened polystyrene block and polyethylene -In the high-molecular-weight copolymer of propylene block, mix 20min with the rotating speed of 100r / min, make it mix to form uniform molten substance, then vacuum defoaming, obtain hydrocolloid;

[0040] 2. Preparation of hydrocolloid dressing

[0041] Transfer the hydrocolloid after vacuum defoaming to the glue tank in the hot-melt adhesive doubl...

Embodiment 3

[0042] Embodiment 3: prepare described hydrocolloid and hydrocolloid dressing

[0043] 1. Preparation of hydrocolloids

[0044] Take 30 parts of high molecular weight copolymers of polystyrene block and polyethylene-butylene block and 15 parts of liquid paraffin in proportion by weight, and soften in a reaction kettle at a temperature of 200° C. for 40 minutes;

[0045] Adjust the temperature, and after the temperature drops to 100°C, take 10 parts of lanolin, 40 parts of sodium carboxymethyl cellulose, and 10 parts of sodium hyaluronate according to the weight ratio, and put them into the softened polystyrene block and polyethylene -In the high molecular weight copolymer of butene block, mix 30min with the rotating speed of 120r / min, make it mix to form uniform molten substance, vacuum defoaming then, obtain hydrocolloid;

[0046] 2. Preparation of hydrocolloid dressing

[0047] Transfer the hydrocolloid after vacuum defoaming to the glue tank in the hot-melt adhesive doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com