Antibacterial and hydrophilic softening finishing agent for cotton fabric and preparation method of softening finishing agent

A soft finishing agent and cotton fabric technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems that cotton fiber is easy to breed bacteria, easy to breed bacteria, cotton fiber is hard, etc., and achieves easy control of the reaction process, excellent Soft touch, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

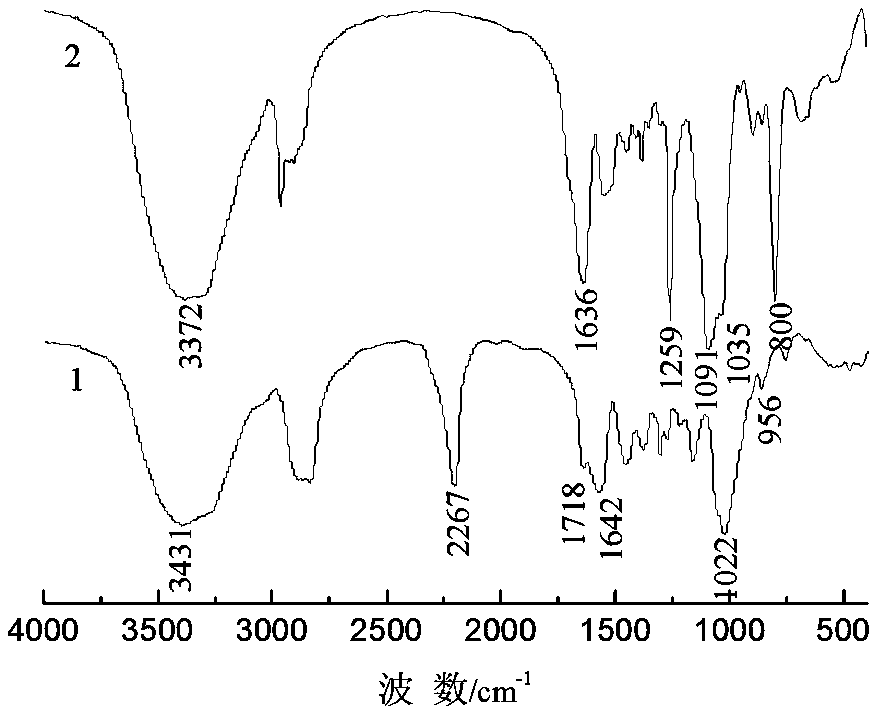

Method used

Image

Examples

Embodiment 1

[0041] The steps of present embodiment preparation for the antibacterial and hydrophilic softening agent of cotton fabric are as follows:

[0042] 1. Add 50 parts of isophorone diisocyanate and 90 parts of tetrahydrofuran-ethylene oxide copolymerized glycol (number average molecular weight is 1000) after vacuum dehydration into the reaction kettle, then add 15 parts of methyl ethyl ketone, and add 0.08 parts of di Dibutyltin laurate was used as a catalyst, the temperature was raised to 80°C, and N 2 protection, heat preservation and reaction for 3 hours and cooling down to obtain a polyurethane prepolymer.

[0043] 2. Add 50 parts of the polyurethane prepolymer obtained in step 1 and 100 parts of hydroxy polydimethylsiloxane into the reaction kettle, raise the temperature to 90°C, keep the temperature for 8 hours, cool down to 25°C, and take 3 parts of polyhexa Methyleneguanidine hydrochloride was dissolved in 3 parts of dimethyl sulfoxide, added to the reaction kettle, and...

Embodiment 2

[0046]1. Add 50 parts of isophorone diisocyanate and 125 parts of tetrahydrofuran-ethylene oxide copolymerized glycol (number average molecular weight: 1000) after vacuum dehydration into the reaction kettle, then add 20 parts of butanone, and add 0.11 parts of di Dibutyltin laurate was used as a catalyst, the temperature was raised to 75°C, and N 2 After protection and heat preservation reaction for 3.5 hours, the polyurethane prepolymer was obtained by cooling and lowering the temperature.

[0047] 2. Add 50 parts of the polyurethane prepolymer obtained in step 1 and 150 parts of hydroxypolydimethylsiloxane into the reaction kettle, raise the temperature to 95°C, keep the temperature for 7.5 hours, cool down to 30°C, and take 3.5 parts of polyhexa Methyleneguanidine hydrochloride was dissolved in 3.5 parts of dimethyl sulfoxide, added to the reaction kettle, and after 2.5 hours of heat preservation reaction, the solvent was removed by suction filtration for 0.5 hours at 75...

Embodiment 3

[0050] 1. Add 50 parts of isophorone diisocyanate and 150 parts of tetrahydrofuran-ethylene oxide copolymerized glycol (number average molecular weight: 1000) after vacuum dehydration into the reaction kettle, then add 25 parts of butanone, and add 0.15g Dibutyltin dilaurate was used as a catalyst, the temperature was raised to 80°C, and N 2 After protection, heat preservation and reaction for 3 hours, the polyurethane prepolymer was obtained by cooling and lowering the temperature.

[0051] 2. Add 50 parts of the polyurethane prepolymer obtained in step 1 and 200 parts of hydroxy polydimethylsiloxane into the reaction kettle, raise the temperature to 100°C, keep the temperature for 7 hours, cool down to 35°C, and take 4 parts of polyhexa Methyleneguanidine hydrochloride was dissolved in 4 parts of dimethyl sulfoxide, added to the reaction kettle, and after 2 hours of heat preservation reaction, the solvent was removed by suction filtration for 0.5 hours at 80°C and 0.1Mpa t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com