Cryogenic treatment process for improving toughness of magnesium alloy

A cryogenic treatment and magnesium alloy technology, applied in the field of metal materials, can solve problems such as numerous process steps, low production efficiency, and not too obvious improvement of alloy plasticity, and achieve the effect of simple process method, high safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

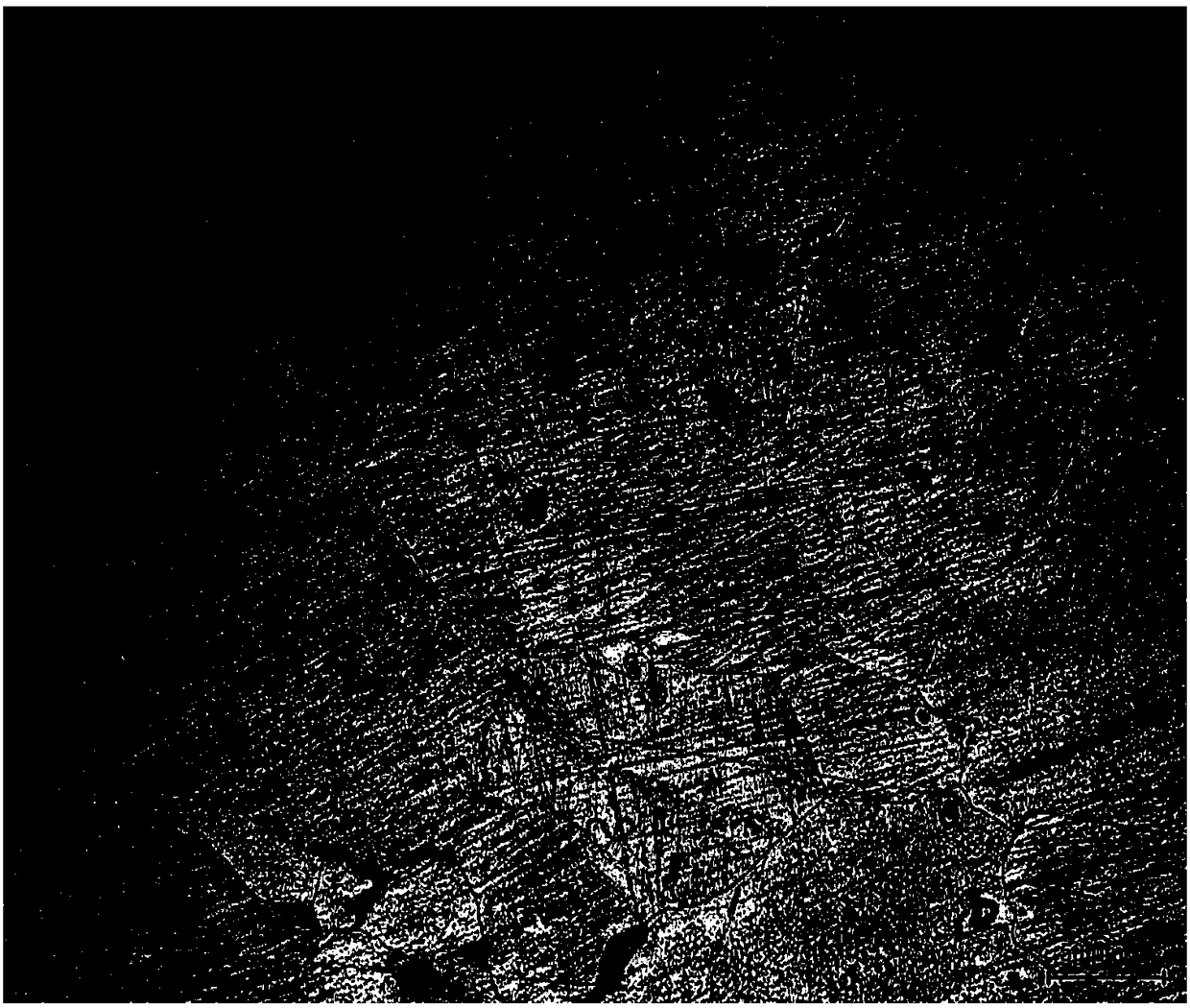

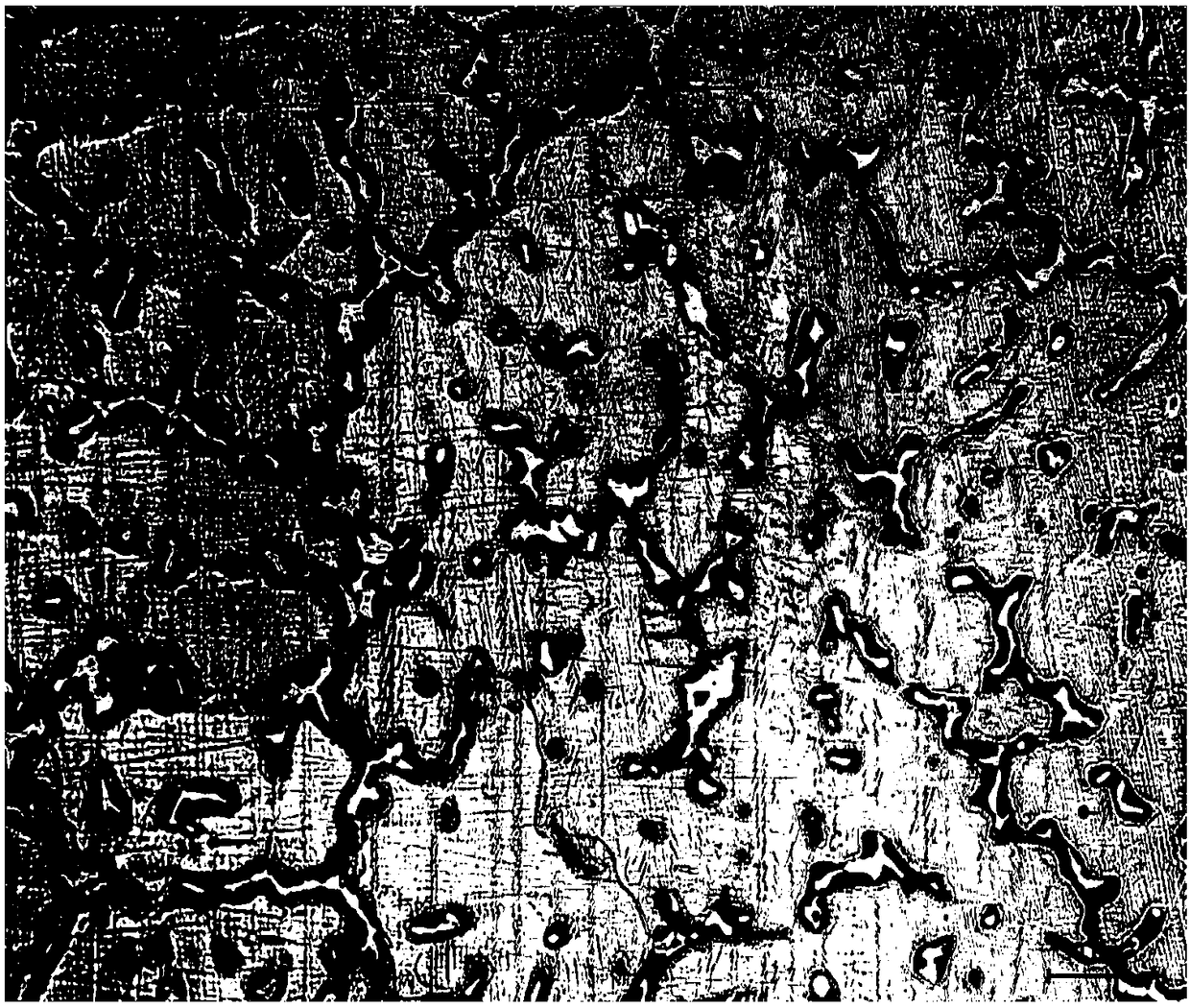

Image

Examples

Embodiment 1

[0039] A cryogenic treatment process for improving the toughness of magnesium alloys, the magnesium alloy used is AZ31, the components contained in the alloy elements and their mass percentages are Al: 2.5-3.0%, Zn: 0.7-1.3%, Mn: 0.17-0.2%, The balance is Mg; before use, the raw materials are weighed according to the components and contents of the AZ31 magnesium alloy, and the raw materials are smelted to obtain the AZ31 magnesium alloy melt.

[0040] The cryogenic treatment process of this AZ31 magnesium alloy, concrete steps are as follows:

[0041] (1) mold preheating

[0042] Preheating the mold to obtain a preheated mold, wherein the preheating temperature is 200-300°C and the preheating time is 1-2h;

[0043] (2) pouring and solidification

[0044] Pouring AZ31 magnesium alloy melt into the preheated mold, after the alloy is solidified, the AZ31 magnesium alloy after solidification is obtained; wherein, a rotating magnetic field is applied during the pouring and solidi...

Embodiment 2

[0054] A cryogenic treatment process for improving the toughness of magnesium alloys. The alloy used is AZ91. The elements contained in the alloy and their mass percentages are: Al: 8.5-9.5%, Zn: 0.45-0.91%, Mn: 0.17-0.4%, Cu: 0.01-0.025%, Ni: 0.001-0.003%, Fe: 0.003-0.006%, and the balance is Mg. Before use, the raw materials are weighed according to the components and contents of the AZ91 magnesium alloy, and the raw materials are smelted to obtain the AZ91 magnesium alloy melt.

[0055] The cryogenic treatment process of this AZ91 magnesium alloy, concrete steps are as follows:

[0056] (1) mold preheating

[0057] Preheating the mold to obtain a preheated mold, wherein the preheating temperature is 100-200°C and the preheating time is 1-2h;

[0058] (2) pouring and solidification

[0059] Pour AZ91 magnesium alloy melt into the preheated mold, after the alloy solidifies, obtain the AZ91 magnesium alloy after solidification; Wherein, all apply rotating magnetic field in ...

Embodiment 3

[0069] A cryogenic treatment process for improving the toughness of magnesium alloys, the magnesium alloy used is AZ31, the components contained in the alloy elements and their mass percentages are Al: 2.5-3.0%, Zn: 0.7-1.3%, Mn: 0.17-0.2%, The balance is Mg; before use, the raw materials are weighed according to the components and contents of the AZ31 magnesium alloy, and the raw materials are smelted to obtain the AZ31 magnesium alloy melt.

[0070] The cryogenic treatment process of this AZ31 magnesium alloy, concrete steps are as follows:

[0071] (1) mold preheating

[0072] Preheating the mold to obtain a preheated mold, wherein the preheating temperature is 300-400°C and the preheating time is 1-2h;

[0073] (2) pouring and solidification

[0074] Pour the AZ31 magnesium alloy melt into the preheated mold, and after the alloy solidifies, the solidified AZ31 magnesium alloy is obtained; wherein, no rotating magnetic field is applied during the pouring process, and a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com