Anti-static plastic carrying belt and production process thereof

A production process and technology of anti-static coatings, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve problems such as large influence on material properties, and achieve the effects of good transparency, excellent mechanical properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 raw material preparation

[0031] The preparation method of polystyrene / poly 3,4-ethylenedioxythiophene composite conductive material comprises the following steps:

[0032] 1) Add 3,4-ethylenedioxythiophene to the aqueous medium system of polystyrene particle emulsion with a solid content of 4-6%, and ultrasonically stir for several hours. The mass ratio of 3,4-ethylenedioxythiophene to the particles in the polystyrene particle emulsion in the system is 1:3-1:12.

[0033] 2) Synthesis of composite particles: the mixed solution prepared in step 1 was stirred for several hours, and then an oxidant was added. Add 0.1-1.0 M doping acid solution dropwise at a rate of 0.25-2.5 mmol / min to the mixed solution. After the dropwise addition is completed, the reaction is performed at a constant temperature of 50-80° C. for 18-24 hours. After the reaction is stopped, it is centrifuged and washed with methanol and water for several times until the solution in the upp...

Embodiment 2

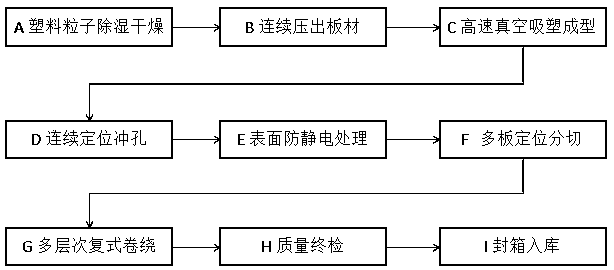

[0041] The production technology of embodiment 2 antistatic plastic carrier tape (adopting the raw material prepared in embodiment 1)

[0042]A. Dehumidification and drying of plastic particles: the raw material is polystyrene / poly 3,4-ethylenedioxythiophene composite conductive material particles, which are baked by the baking mechanism for more than 2 hours to remove the moisture in the raw materials;

[0043] B. Continuously extrude the sheet: the polystyrene / poly 3,4-ethylenedioxythiophene composite conductive material particles baked in step A; through the action of the screw barrel and the heating ring, it forms a liquid state and passes through the die head Form a slurry-type plate shape;

[0044] C. High-speed vacuum blister forming: the plate-like flow slurry enters the forming mold through vacuum adsorption to form the prototype of the multi-plate carrier tape;

[0045] D. Continuous positioning punching: After forming in step C, punching is carried out;

[0046] E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com