Method for producing mineral raw organic fertilizers

A production method and technology of organic fertilizer, applied in the directions of organic fertilizer, inorganic fertilizer, nitrogen fertilizer, etc., can solve the problems of insufficient storage capacity of phosphogypsum slag field, strong sulfuric acid corrosion, affecting production and operation, etc., to promote soil microbial activity, leaching, etc. High rate and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

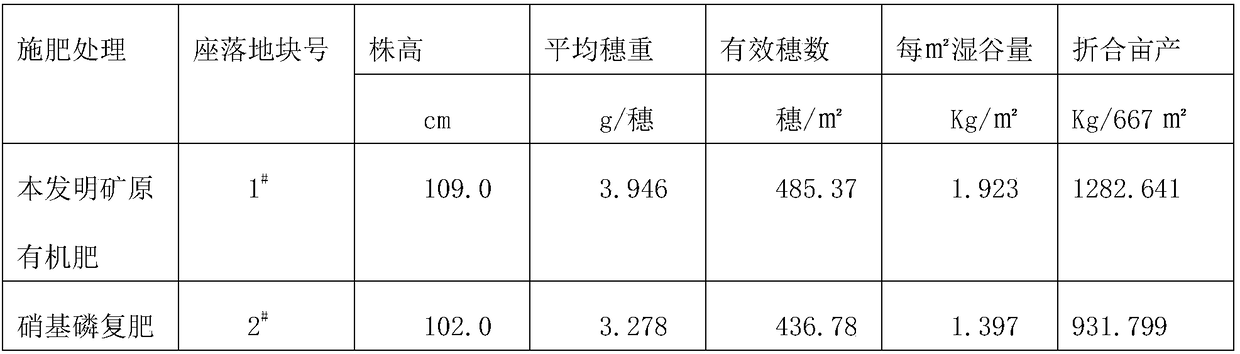

Examples

Embodiment 1

[0024] Weigh 124 parts of sulfuric acid with a concentration of 92% to 95% and 165 parts of nitric acid with a concentration of 56% to 65% by weight, and mix to obtain mixed acid; 197 parts of phosphate rock powder were placed in mixed acid and decomposed under 4KPa negative pressure for 30 minutes; the decomposed material was added to the granulator, and 76 parts by weight of humic acid, 255 parts by weight of potassium sulfate, and 11 parts by weight of MgSO were added simultaneously. 4 ﹒ 7H 2 O magnesium sulfate heptahydrate, 19 parts by weight Na 2 B 4 o 7 ﹒ 10H 2 The decahydrate of sodium O tetraborate, 28 parts by weight ZnSO 4 ﹒ 7H 2 O Joint granulation of zinc sulfate heptahydrate; control the moisture content of the granulator output to 1%, that is, to obtain the required mineral organic fertilizer.

[0025] P in phosphate rock powder 2 o 5 The content is 25.3%-27.5%; the content of water-soluble humic acid in humic acid is 55%-63%. When granulating, the m...

Embodiment 2

[0027] Repeat Example 1, following difference is arranged: take by weighing 159 parts of sulfuric acid and 173 parts of nitric acid and make mixed acid; Phosphate rock is ground to cross 50 mesh sieves, then the phosphor rock powder of 203 weight parts is placed in mixed acid, at 4.5 Decompose under KPa negative pressure for 31 minutes; put the decomposed material into the granulator, and add 81 parts by weight of humic acid, 258 parts by weight of potassium sulfate, and 13 parts by weight of MgSO 4 ﹒ 7H 2 O magnesium sulfate heptahydrate, 20 parts by weight Na 2 B 4 o 7 ﹒ 10H 2 The decahydrate of sodium O tetraborate, 29 parts by weight ZnSO 4 ﹒ 7H 2 Co-granulation of zinc sulfate heptahydrate; control the moisture content of the granulator output to 1.7%, that is, to obtain the required mineral organic fertilizer.

[0028] During granulation, the material residence time is 2.2 minutes, the rotating speed is 9.3 rpm, and the driving motor P=100KW.

Embodiment 3

[0030] Repeat Example 1, following difference is arranged: take by weighing 162 parts of sulfuric acid and 177 parts of nitric acid to make mixed acid; Phosphate rock is ground to cross 60 mesh sieves, then the phosphor rock powder of 205 weight parts is placed in mixed acid, at 4.7 Decompose under KPa negative pressure for 32 minutes; put the decomposed material into the granulator, and add 83 parts by weight of humic acid, 308 parts by weight of potassium sulfate, and 14 parts by weight of MgSO 4 ﹒ 7H 2 O magnesium sulfate heptahydrate, 21 parts by weight Na 2 B 4 o 7 ﹒ 10H 2 The decahydrate of sodium O tetraborate, 30 parts by weight ZnSO 4 ﹒ 7H 2 Co-granulation of zinc sulfate heptahydrate; control the moisture content of the granulator output to 2.3%, that is, to obtain the required mineral organic fertilizer.

[0031] When granulating, the material residence time is 2.5 minutes, the rotating speed is 9.6 rpm, and the driving motor P=100KW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com