Brake device for ink application for color printing equipment

A braking device and equipment technology, applied in the directions of inking device, transmission device, friction transmission device, etc., can solve the problems of complicated operation, low operability and high professionalism of the inking device, and achieve increased convenience, simple operation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] All features disclosed in this specification, or steps in all methods or processes disclosed, can be combined in any way, except for mutually exclusive features and / or steps.

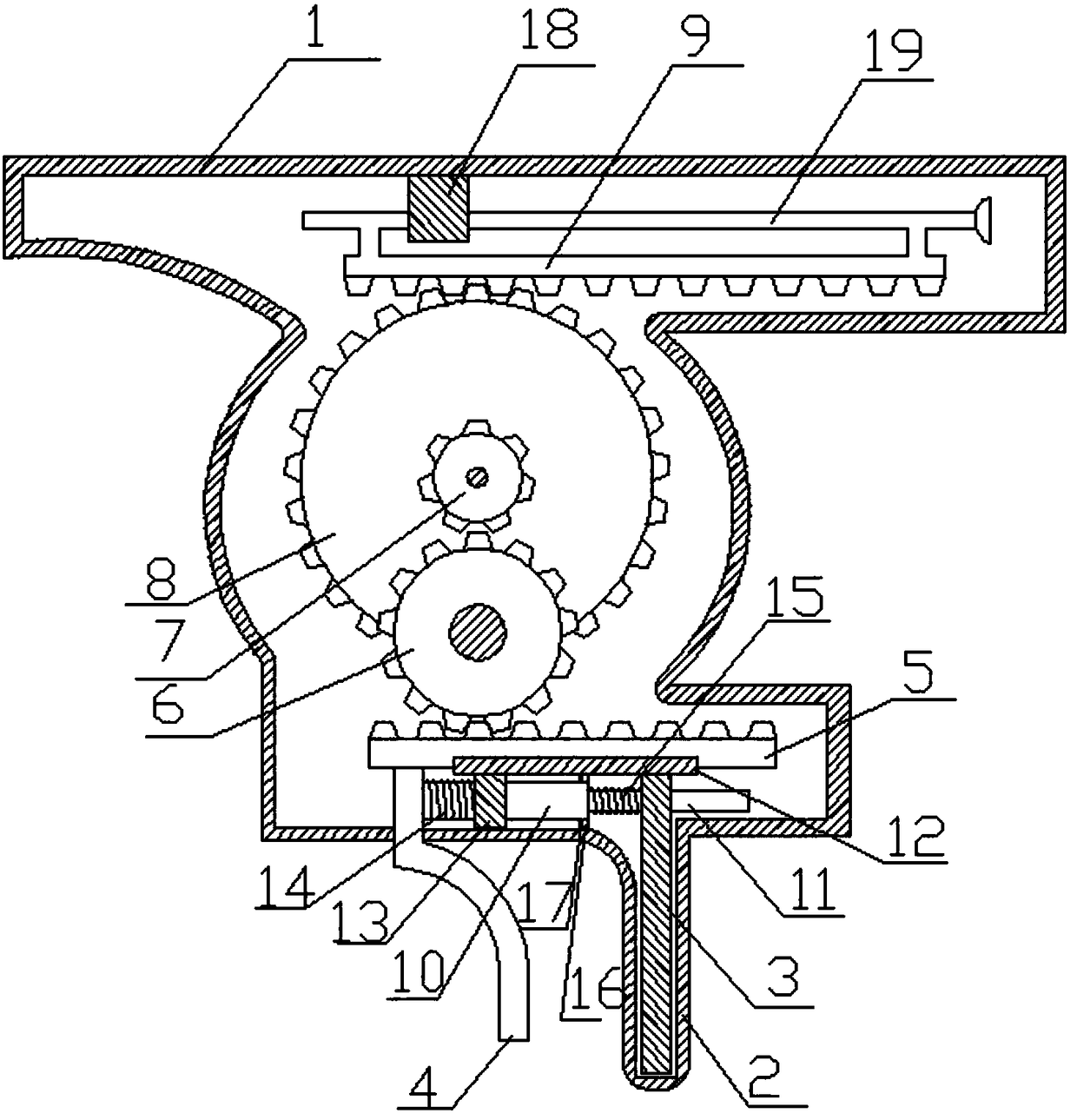

[0030] Combine below figure 1 The present invention will be described in detail.

[0031] A brake device for adding ink to color printing equipment, comprising a housing 1, characterized in that the lower end of the housing 1 is provided with a hollow handshake 2, and a handle 3 is set inside the handshake 2, and the handle 3 The upper end is provided with a through hole, one side of the handshake 2 is provided with a toggle 4, the toggle 4 is connected with a movable rod group capable of moving horizontally, and the end of the toggle 4 connected with the movable rod group is also provided with a first tooth plate 5, The top of the first tooth plate 5 is provided with the first gear 6 meshed with the first tooth plate 5, the top of the first gear 6 is provided with the second gear 7 meshed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com