Size control system used for dual-face grinding machine and safe grinding detection method

A double-sided grinding and size control technology, which is applied to grinding machine tools, grinding devices, manufacturing tools, etc., can solve problems such as high repair costs of CBN grinding wheels, alarm shutdown, and workpiece placement warping or overlapping, etc., to increase placement abnormalities Prompt function, increase the judgment of falling position, simple and quick damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

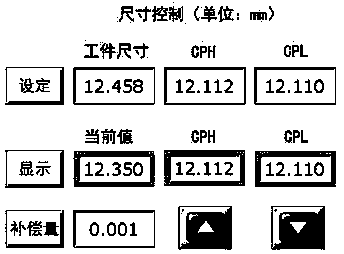

[0024] Dimensional control systems for double-sided grinding machines such as figure 1 As shown, it includes a displacement sensor 4 and a control dimension instrument 3, the displacement sensor 4 is electrically connected to the control dimension instrument 3, the communication terminal of the control dimension instrument 3 is electrically connected to the first communication terminal of the controller 2, and the The second communication end of the controller 2 is electrically connected to the communication end of the touch screen 1, wherein the controller 2 is a PLC, the control size instrument 3 is a LT20A / LT30 counter, and the displacement sensor 4 is a telescopic displacement sensor; In addition, the output end of the controller 2 is electrically connected to an alarm, and the alarm can be an audible alarm, a flashing alarm, or an audible and visual alarm.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com