Automatic feeding type grinding wheel cutting machine

A grinding wheel cutting machine and automatic feeding technology, which is applied to the grinding frame, grinding drive device, grinding machine parts and other directions, can solve the problems of laborious operation of operators, uneven cutting surface, low work efficiency, etc. To achieve the effect of good cutting effect, high safety performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

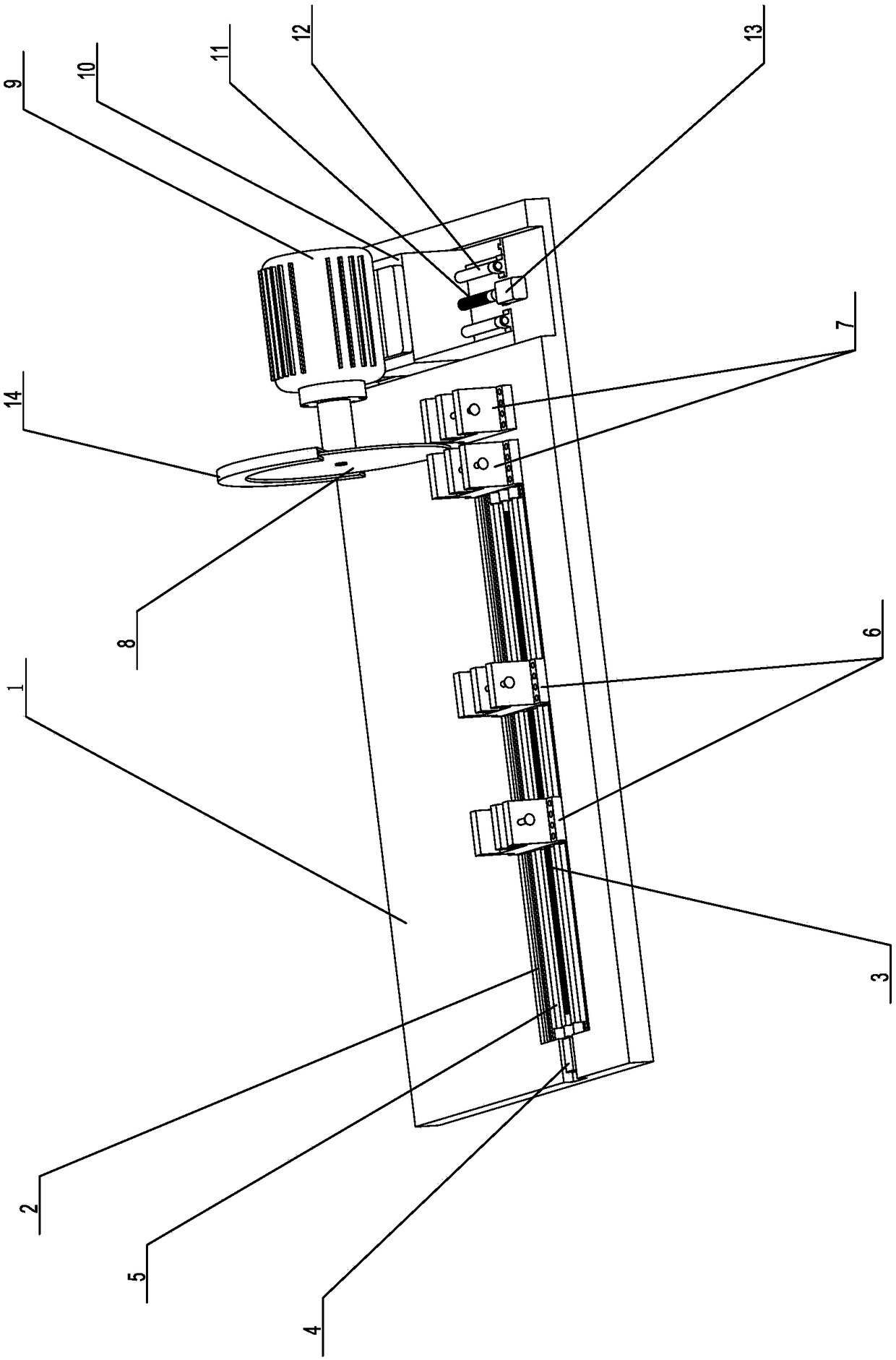

[0016] Such as figure 1 Propose a kind of specific embodiment of the present invention as shown, automatic feeding type grinding wheel cutting machine, comprise the bottom plate 1 that is rectangular shape, described bottom plate 1 surface offers a groove 2 along its lengthwise direction, in described groove 2, set There is an X-axis ball screw 3, the end of the X-axis ball screw 3 is connected to an X-axis motor 4, and the groove 2 is also provided with X-axis guide rails 5 located on both sides of the X-axis ball screw 3, The X-axis ball screw 3 and the two X-axis guide rails 5 successively run through several movable fixtures 6, and the movable fixture 6 moves linearly along the two X-axis guide rails 5 driven by the X-axis ball screw 3, and moves adjacently The distance between the clamps 6 is equal, two fixed clamps 7 are provided on the bottom plate 1 and at the end of the groove 2, the two fixed clamps 7 and the movable clamps 6 are all located on the same straight line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com