A brush type flux recovery port

A technology for recycling port and flux, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low efficiency of flux recovery, improve the effect of flux recovery, avoid falling off or loosening, and slow down the moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

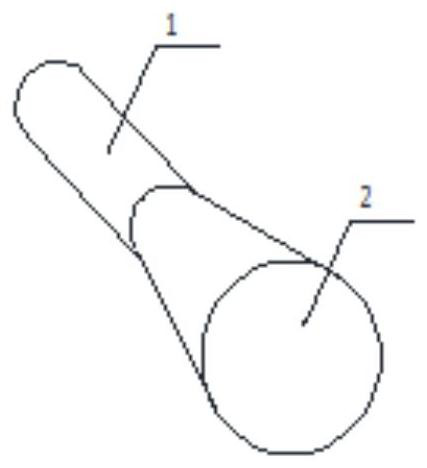

[0039] Such as image 3 with Figure 8 As shown, a brush-type flux recovery port includes a suction pipe 1 and a suction port 2, and also includes a baffle 4. One end of the suction port 2 is connected to the bottom of the suction pipe 1, and the other end of the suction port 2 is connected to a baffle 4. The plate 4 is semi-arc, and the setting of the semi-arc baffle 4 can effectively prevent the movement of the flux. At this time, all the flux is blocked in the adsorption area of the suction port 2, thereby ensuring that the flux can be completely recovered, and at the same time, the rigid welding slag in the adsorption area The generated force is not enough to affect the normal rotation of the cylinder. The brush-type flux recovery port communicates with the flux recovery pipe (i.e. the hose 9), and transports the recovered flux to the flux recovery conveyor;

[0040] The baffle 4 itself can be made of flexible high-temperature-resistant material (for example, asbestos ...

Embodiment 2

[0043] Such as image 3 As shown, the brush-type flux recovery port of this embodiment is similar to that of Embodiment 1, the difference is that a transition baffle 3 is provided between the suction port 2 and the baffle 4, and one end of the transition baffle 3 is connected to the suction port 2 The other end of transition baffle 3 is connected with baffle 4. Wherein the transition baffle 3 is a tapered structure.

[0044] In this embodiment, the setting of the transition baffle plate 3 with a tapered structure not only increases the area where the suction force of the suction port 2 acts, but also effectively slows down the moving speed of the flux at the tail of the cone.

Embodiment 3

[0046] Such as image 3 As shown, the brush-type flux recovery port of this embodiment is similar to that of Embodiment 2, the difference is that it also includes a brush 5, which is fixed on the baffle 4, and the brush 5 is made of a high-temperature-resistant flexible material. The specific application The high temperature resistant flexible material can be selected from stainless steel wire, tungsten wire or aluminum wire.

[0047] The setting of the brush 5 in this embodiment can realize the retention effect on the flux, and then slow down the rotation speed of the flux with the cylinder body, and the flux recovery effect is greatly improved; at the same time, the brush 5 is made of a high-temperature-resistant flexible material to avoid welding. The welding slag produced a direct impact on the baffle plate 4, thereby causing the vibration of the entire brush-type flux recovery port, affecting the normal progress of welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com