Ternary Cu-Co-P (copper-cobalt-phosphor) nanorod as well as preparation method and application thereof

A cu-co-p, nanorod technology, applied in chemical instruments and methods, electrodes, electrolysis process, etc., to achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

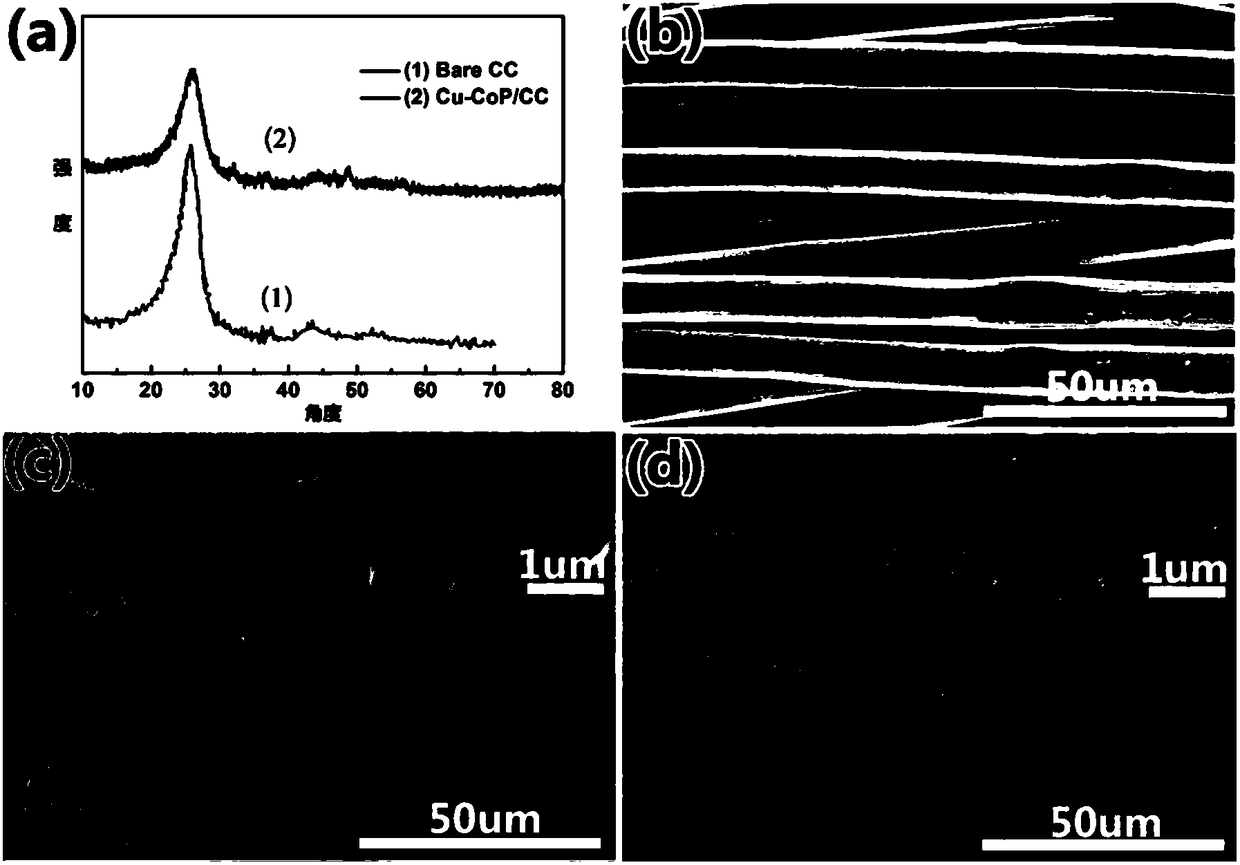

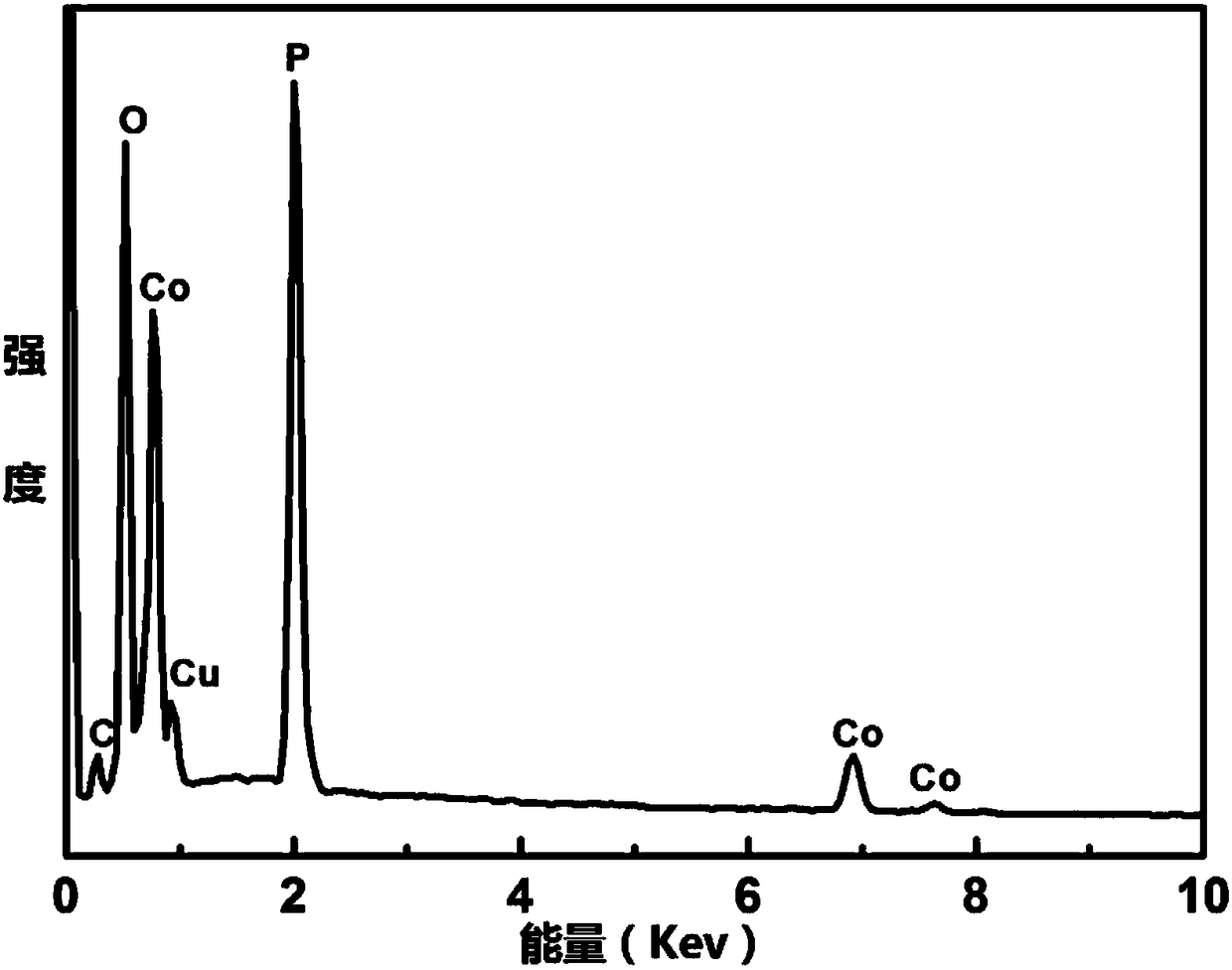

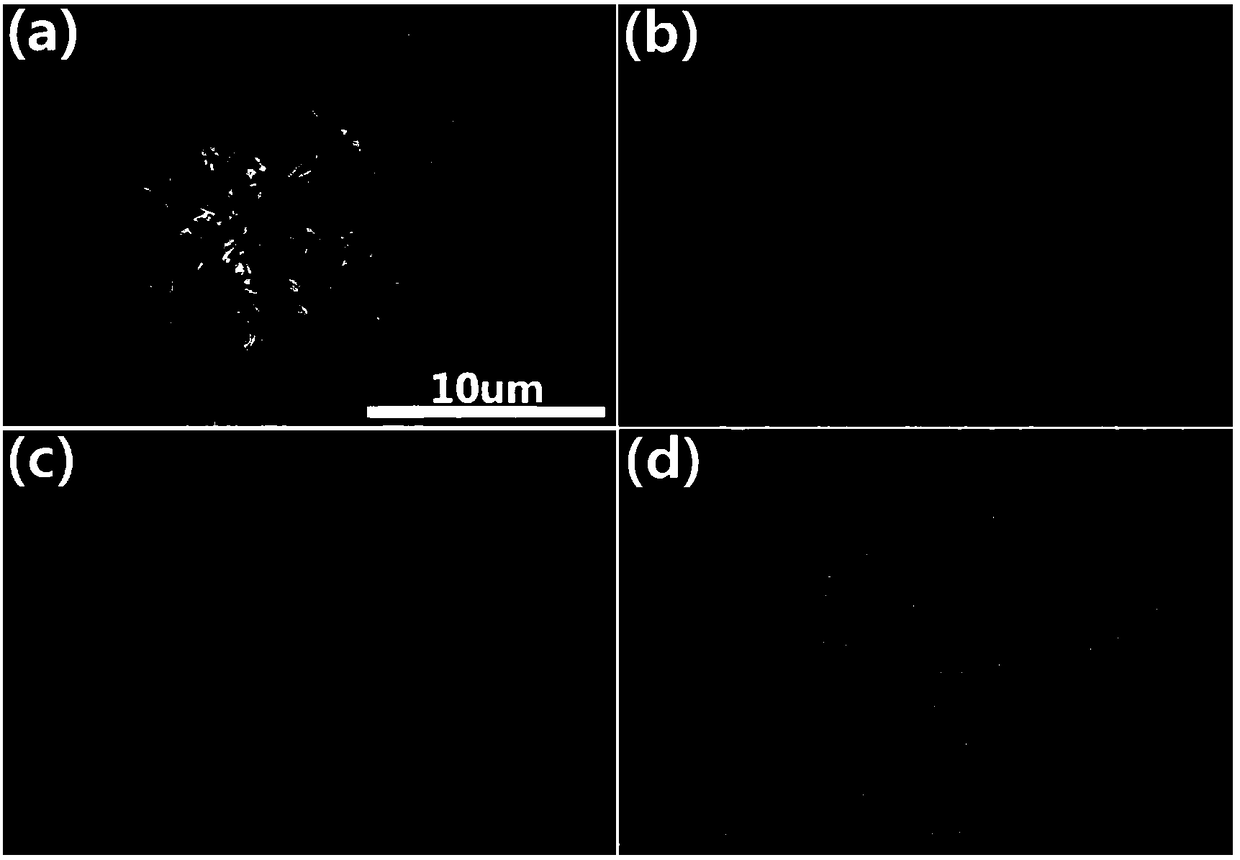

[0026] A preparation method of ternary Cu-Co-P nanorods, comprising the steps of:

[0027] Step A, mixing copper nitrate, cobalt nitrate, urea, and ammonium fluoride together in water, making the concentration of copper nitrate in the mixed solution be 0.2 to 1.0 mmol / liter, and the concentration of cobalt nitrate to be 5.0 to 6.0 mmol / liter, The concentration of urea is 15.0-25.0 mmol / L, and the concentration of ammonium fluoride is 6.0-10.0 mmol / L, so as to prepare the precursor mixed solution.

[0028] Step B, placing the substrate in the precursor mixed solution, and transferring the substrate and the precursor mixed solution into an autoclave, and then reacting at 100-120° C. for 480-600 minutes, so that the CuCo-LDH nanorods were prepared on the above substrate.

[0029] Step C, drying the substrate and the CuCo-LDH nanorods on the substrate, and then according to the mass ratio of the precursor mixed solution: sodium hypophosphite = 1:20, the dried substrate together w...

Embodiment 1

[0039] A preparation method of ternary Cu-Co-P nanorods, comprising the steps of:

[0040] Step a, copper nitrate, cobalt nitrate, urea, ammonium fluoride are mixed together in water, make the concentration of copper nitrate in the solution after mixing be 0.6 mmol / liter, cobalt nitrate concentration be 6.0 mmol / liter, urea concentration be 20.0 mmol / L, the ammonium fluoride concentration is 8.0 mmol / L, thereby preparing the precursor mixed solution.

[0041] Step b, using carbon cloth (CC) with a size of 1×4cm as the substrate, placing the substrate in the precursor mixed solution, and transferring the substrate and the precursor mixed solution to a 50mL autoclave , and then reacted at 110°C for 480 minutes to prepare CuCo-LDH nanorods on the substrate.

[0042] Step c, drying the substrate and the CuCo-LDH nanorods on the substrate, and then according to the mass ratio of the precursor mixed solution: sodium hypophosphite = 1:20, the dried substrate together with the CuCo-L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com