Method for formation and capacity grading of lithium ion battery with silicon-carbon cathode

A lithium-ion battery and silicon carbon technology, applied in the field of lithium-ion batteries, can solve the problems of large volume expansion, battery swelling, cycle performance degradation, and electrolyte consumption, so as to reduce volume expansion, avoid electrolyte loss, and alleviate volume expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

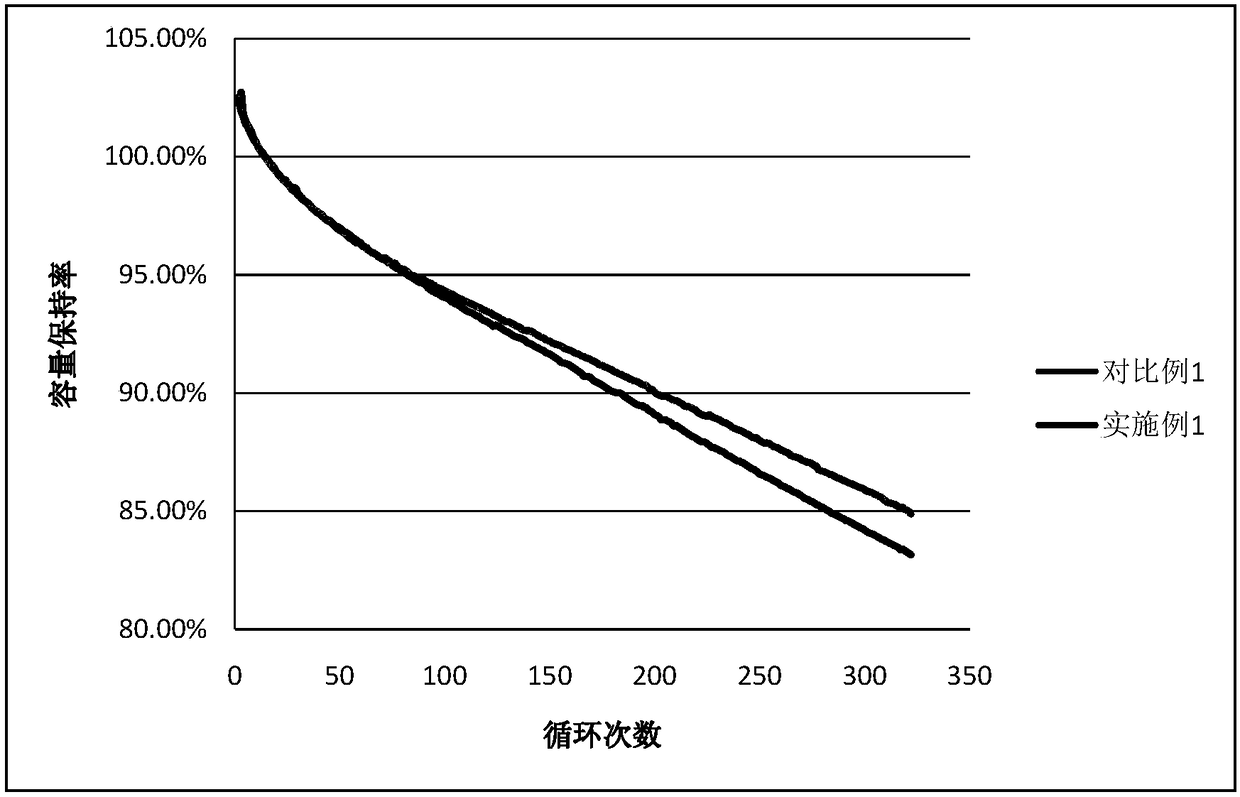

Embodiment 1

[0027] A lithium ion battery formation and capacity method using silicon carbon as the negative electrode, comprising the steps of:

[0028] S1. Place the unsealed iron-lithium battery cell on the cabinet after the injection and aging for formation; the temperature during the formation process is greater than or equal to 25°C, and the dew point temperature is less than or equal to -10°C; to 0.02C, and then use a large current to form it for 2 hours, and the charging rate is 0.2C to obtain the first battery cell;

[0029] S2. Perform high-temperature aging treatment on the first battery cell for 12 hours, the temperature of the high-temperature aging treatment is 45°C, and the vacuum degree of the high-temperature aging treatment is -90kPa, to obtain the second battery cell;

[0030] S3. Transfer the second battery cell to the liquid injection room, exhaust, replenish liquid, and stand at room temperature for 12 hours to obtain the third battery cell;

[0031] S4. Put the thir...

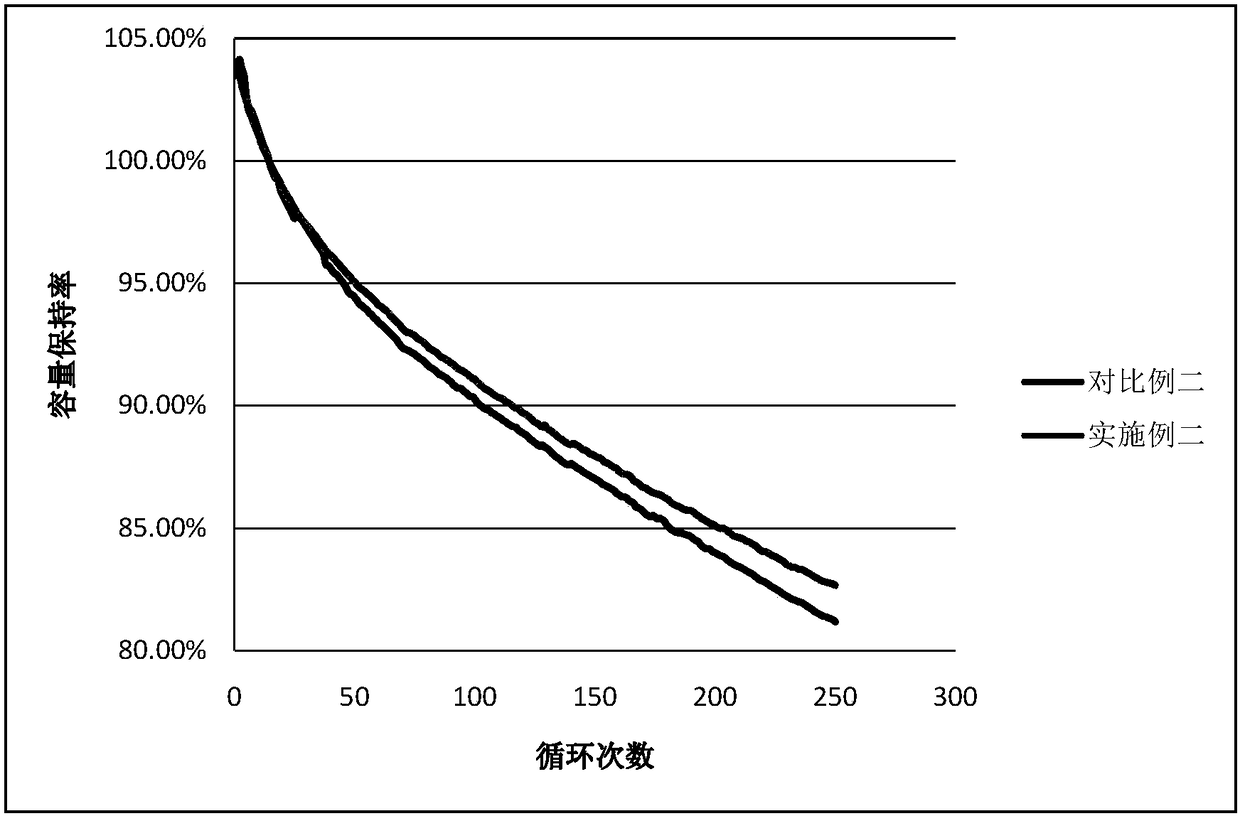

Embodiment 2

[0034] A lithium ion battery formation and capacity method using silicon carbon as the negative electrode, comprising the steps of:

[0035] S1. Put the unsealed ternary batteries after injection and aging into the cabinet for formation; the temperature during the formation process is greater than or equal to 25°C, and the dew point temperature is less than or equal to -10°C; the specific operation of the formation is as follows: first, use a small current to form for 4 hours, charge The rate is 0.02C, and then the high current is used for 2 hours, and the charge rate is 0.2C, and the first cell is obtained;

[0036] S2. Perform high-temperature aging treatment on the first battery cell for 12 hours, the temperature of the high-temperature aging treatment is 45°C, and the vacuum degree of the high-temperature aging treatment is -90kPa, to obtain the second battery cell;

[0037] S3. Transfer the second battery cell to the liquid injection room, exhaust, replenish liquid, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com