A combined columnar chip enhanced boiling heat transfer microstructure and its manufacturing method

A boiling-enhancing, combined technology, used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc., to improve nucleate boiling heat transfer performance and critical heat flux density, increase critical heat flux density, and greatly attract force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

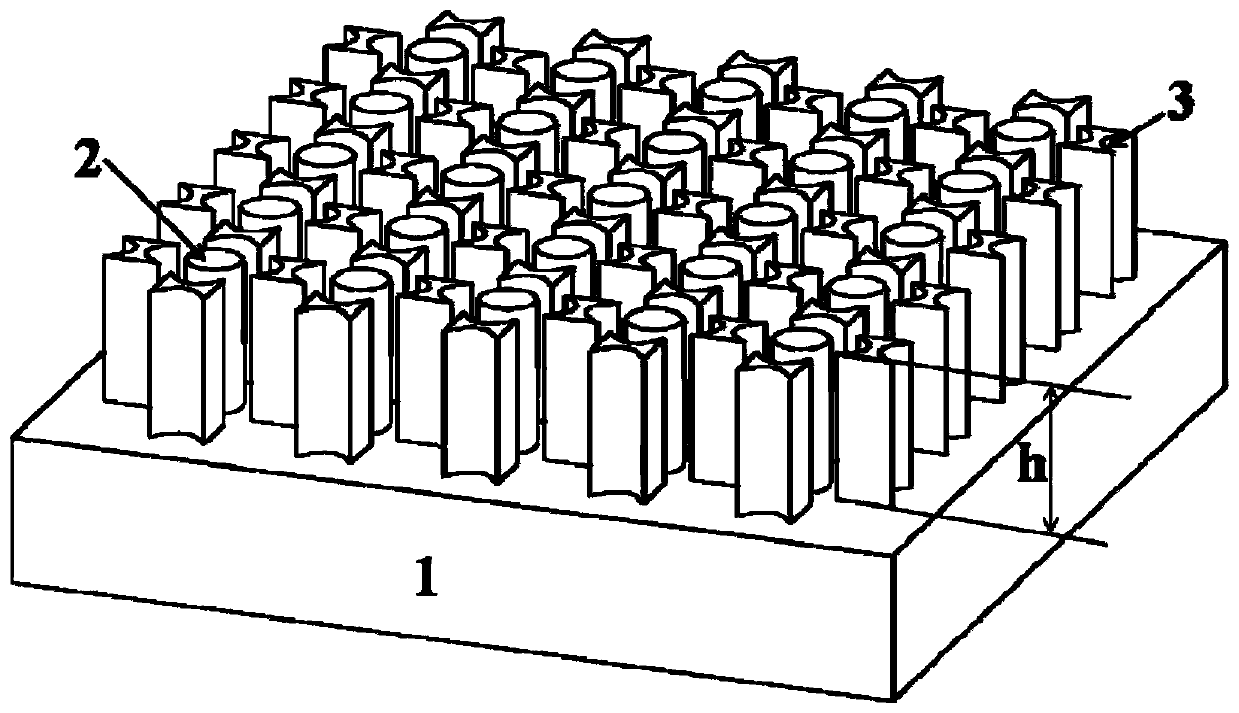

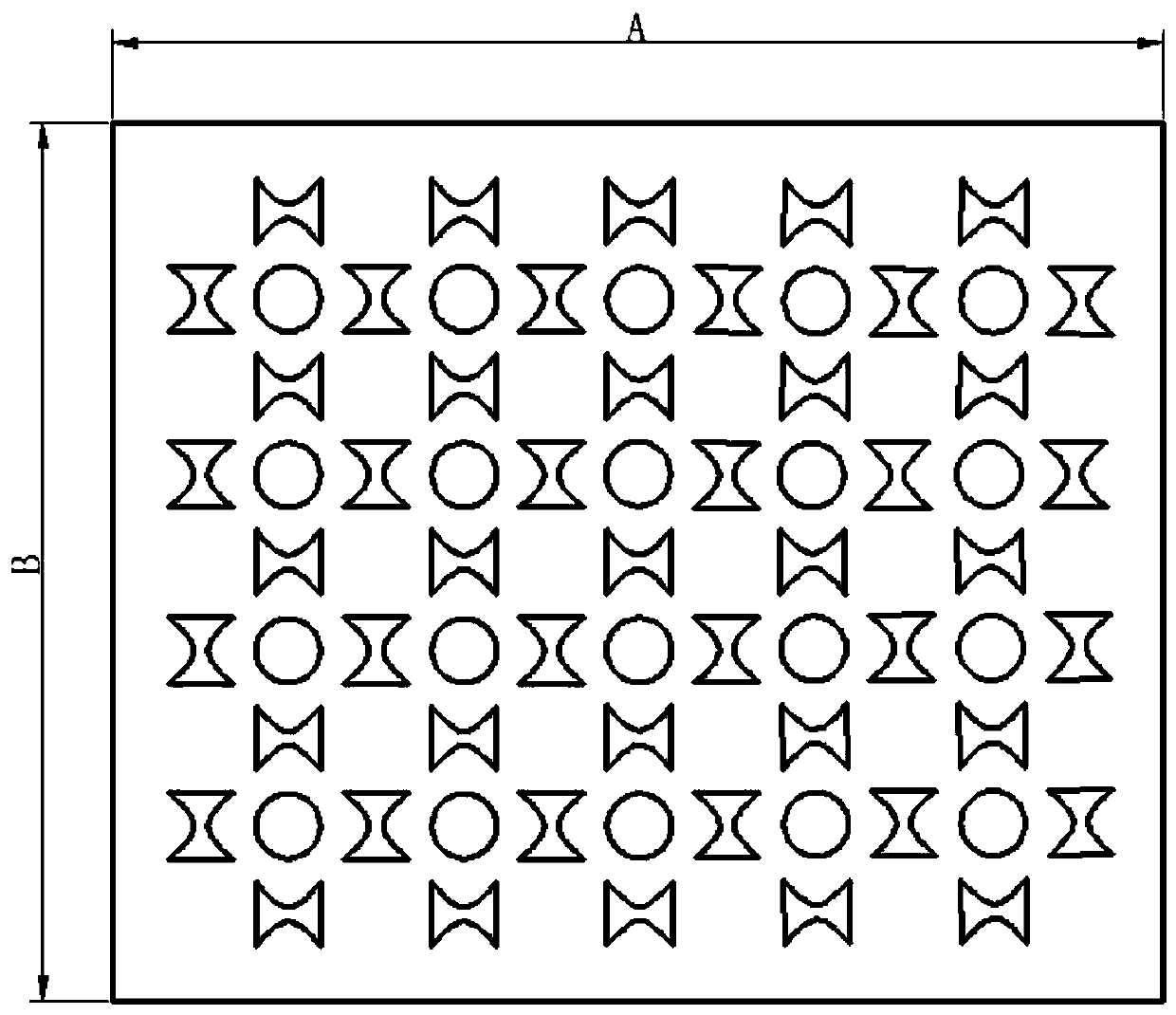

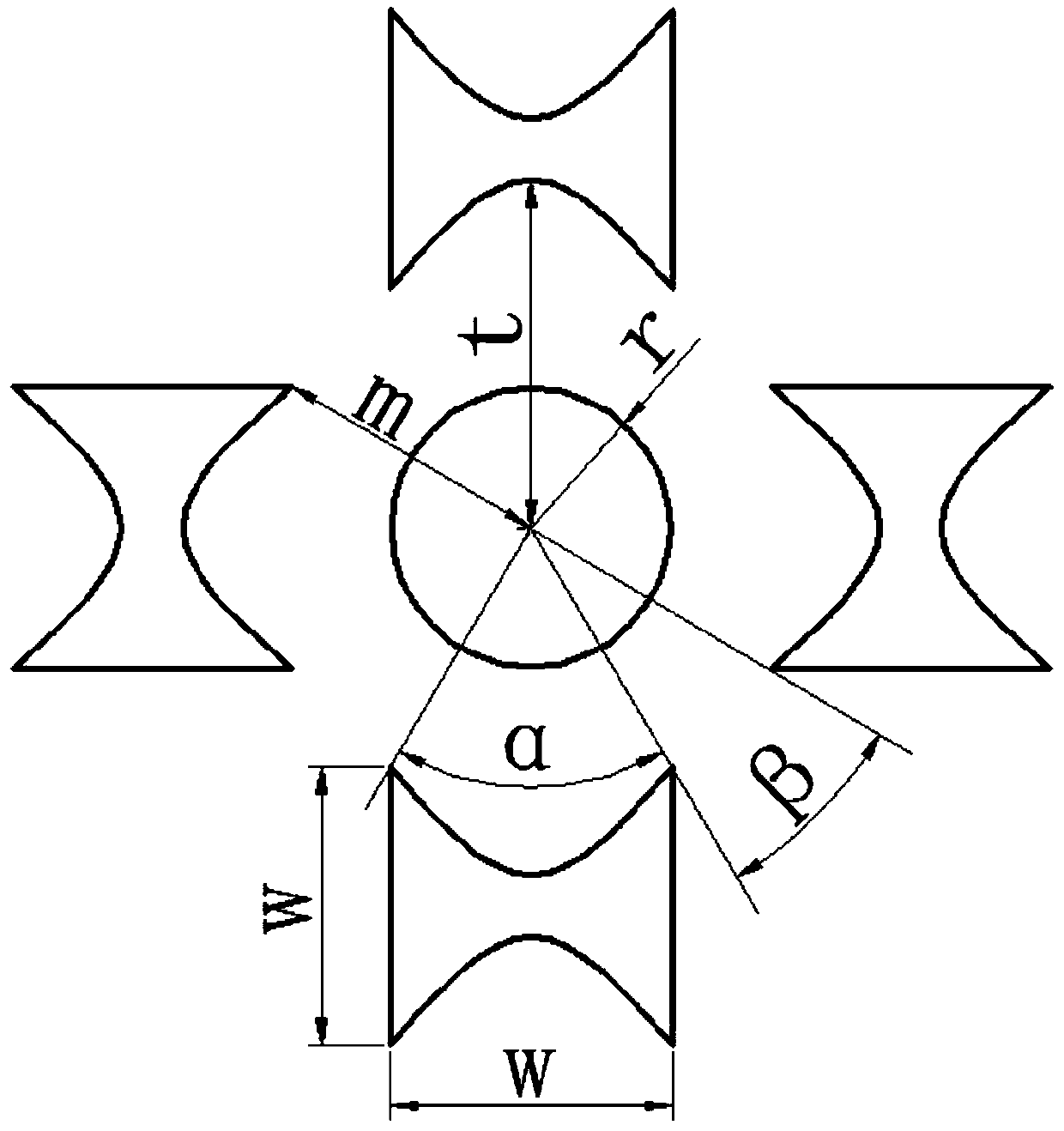

[0029] see Figure 1 to Figure 3 , the purpose of the present invention is to utilize simultaneously "increasing the number of vaporization cores, enhancing capillary force, reducing flow resistance, separating the path of bubble separation and liquid replenishment" to provide a heat transfer device with high heat transfer efficiency and increased capillary pressure head. The function is to reduce the flow resistance and increase the critical heat flux. The chip enhanced boiling heat transfer structure of the micro-column variable curvature surface includes the heat dissipation plate 1 on the surface of the chip and several combined units formed on the heat dissipation plate 1 by dry etching technology. , the combined units are distributed in an array, each combined unit is composed of five micro-columns, the center of each combined unit is a cylindrical micro-column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com