Liquid lithium injection device applied to fusion device and provided with sealing structure

A technology of sealing structure and injection device, applied in the field of fusion reactors, can solve the problems of pollution, damage, blockage of pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

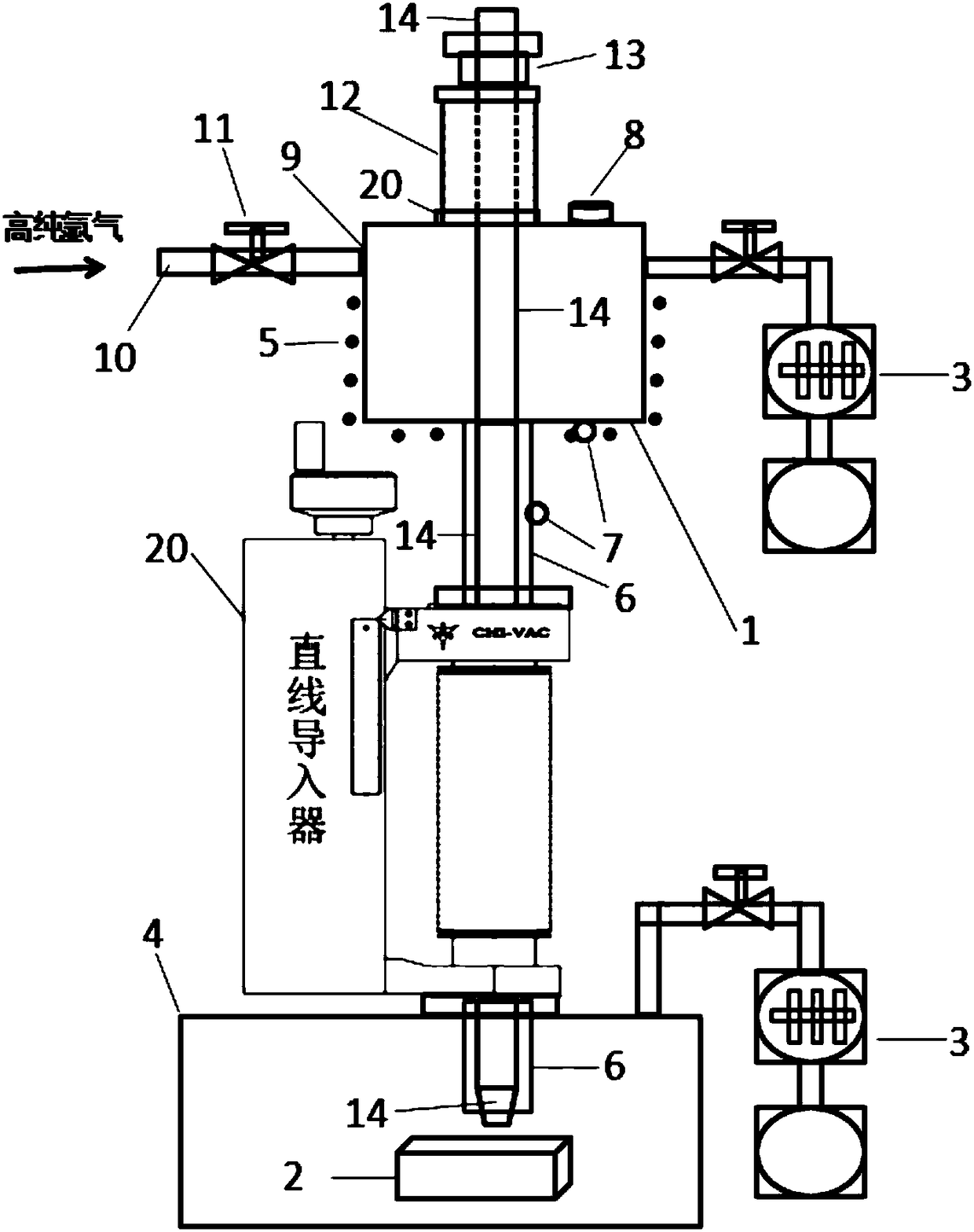

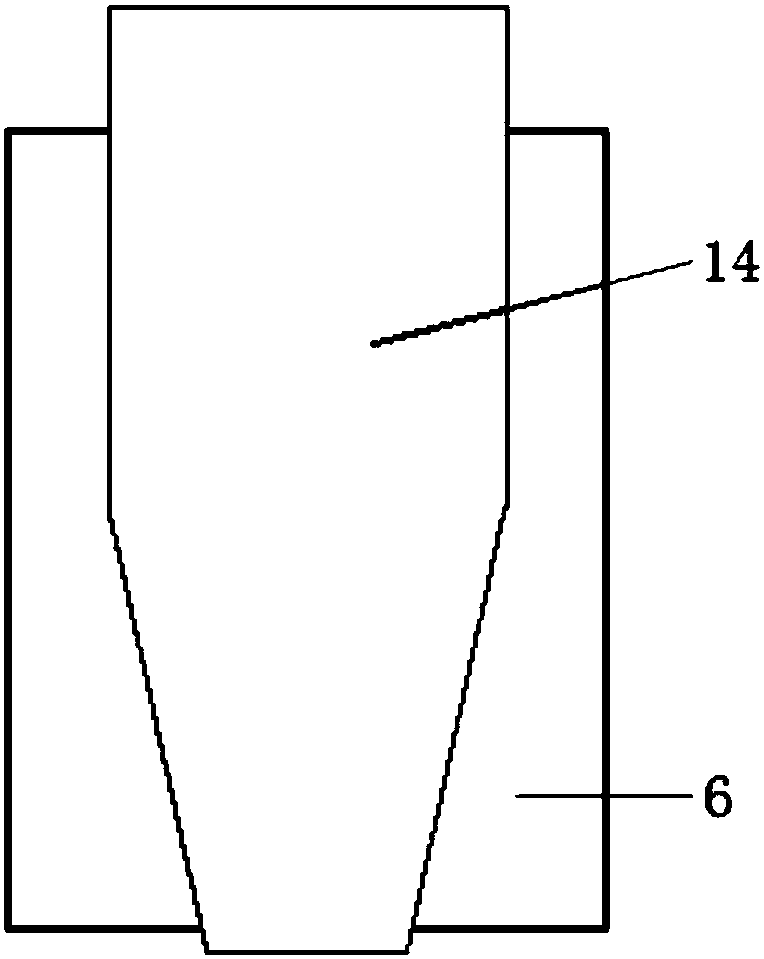

[0016] Such as figure 1 As shown, a liquid lithium injection device with a sealed structure for a fusion device includes a molten lithium tank 1, a lithium storage tank 2 and two sets of molecular pump units 3, and the lithium storage tank 2 is located in a vacuum box 4, a heating device 5 is installed on the outside of the lithium melting tank 1, a lithium injection pipeline 6 is provided under the lithium melting tank 1, and a thermocouple 7 is respectively provided on the outside of the lithium melting tank 1 and the lithium injection pipeline 6, The bottom of the lithium injection pipeline 6 is located above the lithium storage tank 2 in the vacuum box 4, and the two sets of molecular pump units 3 are connected to the melting lithium tank 1 and the vacuum box 4 respectively, and the lithium melting tank 1 There is a feeding port 8 and an argon gas inlet 9 on the top, the argon gas inlet 9 is connected with an argon gas filling pipeline 10, an angle valve 11 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com