Method for characterizing multi-phase interface of polymer bonded explosive

A technology for bonding explosives and polymers, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problem of being unable to distinguish different types of internal interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Controlling the contrast of PBX based on deuterated polyurethane

[0035] The contrast of PBX is regulated by using fully deuterated polyurethane and non-deuterated polyurethane blend binder. The mass ratio between explosive crystals and binder in the PBX sample is 95:5, and the ratio shown in Table 1 is adopted. Five kinds of molding powders with a proportion of components are used to control the contrast difference between HMX explosive crystals and polyurethane binders, named HdP1, HdP2, HdP3, HdP4 and HdP5, where the binder of HdP1 is non-deuterated polyurethane , the binding agent of HdP5 is all deuterated polyurethane, selects 1-2-dichloroethane as the solvent of polyurethane and granulates by water suspension method to obtain modeling powder.

[0036] Table 1. Composition design and neutron scattering length density of a series of contrast-transformed PBX samples in Example 1

[0037]

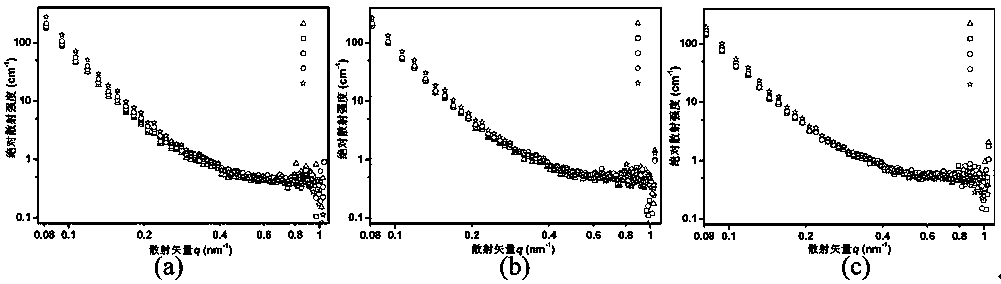

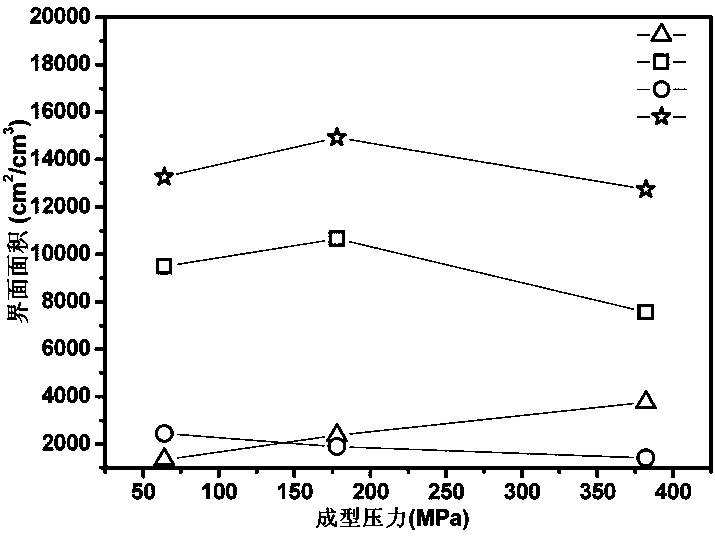

[0038]The molding powder was molded under pressures of 5kN, 14k...

Embodiment 2

[0045] Example 2 Controlling the contrast of PBX based on deuterated HMX

[0046] The contrast of the PBX is regulated by using all-deuterated HMX and non-deuterated HMX blended explosive crystals. The mass ratio between the explosive crystals and the binder in the PBX sample is 95:5. A molding powder with a component ratio is used to control the contrast difference between the HMX explosive crystal and the fluororubber binder, named dHP1, dHP2, dHP3, dHP4 and dHP5, where the explosive crystal of dHP1 is non-deuterated HMX, The explosive crystal of dHP5 is all-deuterated HMX, and ethyl acetate is used as the solvent of fluororubber and granulated by water suspension method to obtain modeling powder.

[0047] Table 3 Composition design and neutron scattering length density of a series of contrast-transformed PBX samples in Example 2

[0048]

[0049] The molding powders were respectively molded under a pressure of 14kN (corresponding to a sample pressure of 178MPa) to obtai...

Embodiment 3

[0053] Example 3 Controlling the contrast of PBX based on deuterated fluororubber

[0054] The contrast of PBX is regulated by using all-deuterated fluororubber and non-deuterated fluororubber blend binder. The mass ratio between TATB explosive crystals and binder in the PBX sample is 95:5. The molding powders with the five component ratios shown are used to control the contrast difference between the explosive crystal and the fluororubber binder, named as TdF1, TdF2, TdF3, TdF4 and TdF5, and the binder of TdF1 is non- Deuterated fluororubber, the binder of TdF5 is full deuterated fluororubber, select ethyl acetate as the solvent of fluororubber and water suspension method to granulate to obtain modeling powder.

[0055] Table 4. Composition design and neutron scattering length density of a series of contrast-transformed PBX samples in Example 3

[0056]

[0057] The molding powders were respectively molded under a pressure of 14kN (corresponding to a sample pressure of 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com