Joint-filling adhesive and road-joint repairing process applying same

A seam glue and road technology, applied in the field of seam glue and road gap repair technology, can solve the problems of poor adhesion and flexibility, reduce the service life of the road surface, damage the road surface, etc., achieve good acid and alkali resistance, and ensure sealing effect, good tensile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

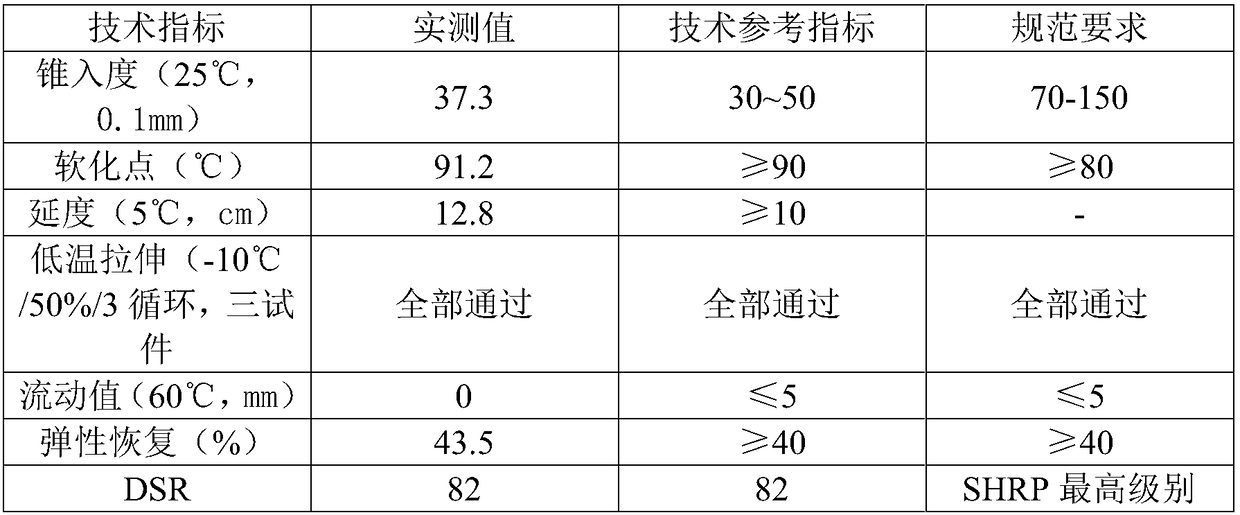

Method used

Image

Examples

Embodiment Construction

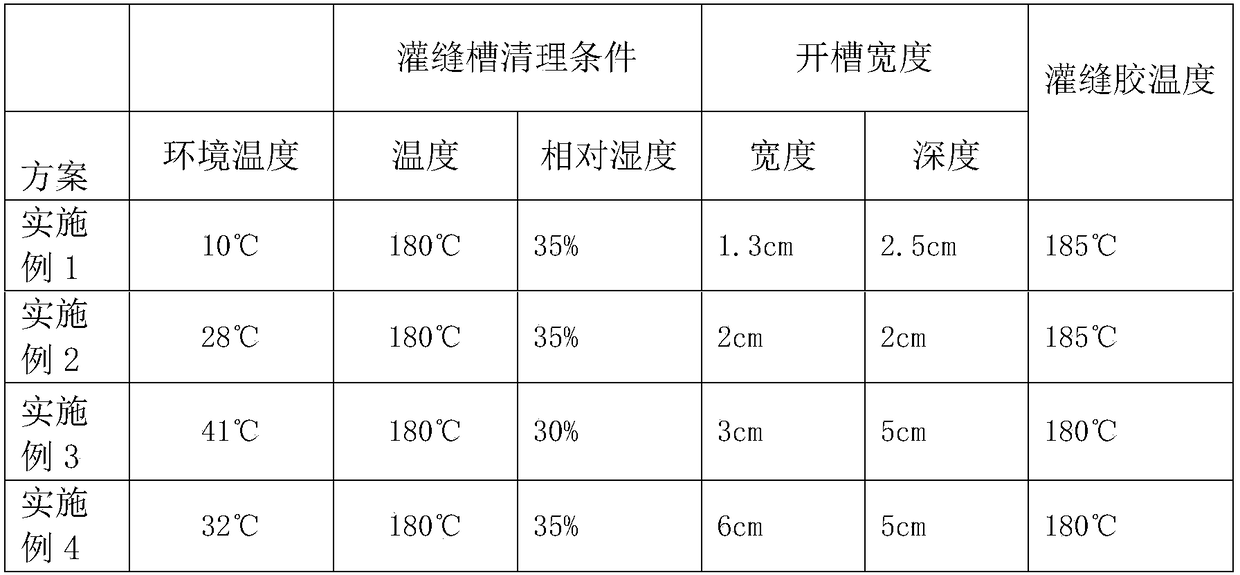

[0021] In conjunction with specific embodiments 1 to 4, a kind of joint filling glue of the present invention and a road gap repair process using the filling glue are illustrated:

[0022] A road gap repairing technique for applying gap glue, comprising the steps of:

[0023] 1) Cutting and grooving: Aiming at the damaged gaps on the road surface, cutting and grooving shall be carried out according to the standard operation. The groove width is 1.3-3cm, the groove depth is less than 3cm, and when the groove width is 3-6cm, dry stones shall be laid on the lower part, and glue shall be poured on the upper part 2cm Covering, dust-free operation is adopted in the process;

[0024] 2) Cleaning of seam filling: clean the seam filling tank with high-pressure hot air from a hot spray gun, set the temperature of the hot spray gun at 1500°C, use an air source pressure of 0.2-0.5Mpa, and clean the seam at a speed of 10m / min in summer and 5m / min in winter. ;

[0025] 3) Joint filling op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com