Anti-blocking PVB (Polyvinyl Butyral) rubber sheet with long-term isolating membrane-free protection at temperature greater than 10 DEG C and preparation method thereof

An anti-blocking, non-isolation technology, applied in the direction of film/sheet adhesive, film/sheet without carrier, adhesive, etc., can solve the adverse effects of haze, light transmittance, and adhesion of laminated glass products , anti-adhesive agent can not reach the anti-adhesion effect of the isolation film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

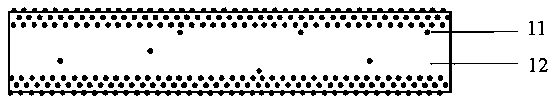

[0047] Add anti-blocking agent before PVB film molding, and add anti-blocking agent to the surface of PVB molten rubber to manufacture single-layer PVB film that does not need isolation film protection when the temperature is greater than 10°C. The specific process is as follows:

[0048] ⑴95 extruder and other equipment form a PVB production line;

[0049] (2) PVB resin powder is fed to 95 machines through weight loss weighing A, and its feed rate is 72 parts by weight / minute, and the feed port is the powder feed port of the extruder;

[0050] (3) the anti-blocking agent butyric acid of 0.01 weight part, the 3GO plasticizer of 26 weight parts, the 1010 antioxidant of 0.2 weight part, the 328 ultraviolet absorber of 0.2 weight part, the sodium acetate knock value regulator of 0.09 weight part , 0.5 parts by weight of water are uniformly mixed after weight loss weighing B also to this 95 machine feed, feed port is the first oil injection port of this extruder, and its feed rate...

Embodiment 2

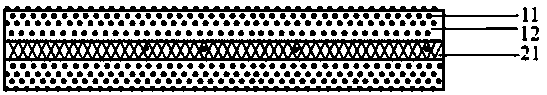

[0058] Add anti-blocking agent before PVB film molding, and mix anti-blocking agent into a mixture of more than one raw material to manufacture anti-blocking three-layer PVB film without isolation film protection at temperatures above 10°C. The specific process is as follows:

[0059] (1) With the anti-blocking agent erucamide of 0.01 weight part, the PVB resin powder of 54 weight parts, the 3GO plasticizer of 45 weight parts, the ultraviolet absorber 328 of the antioxidant 1010 of 0.2 weight part, 0.2 weight part, 0.09 weight part The knocking value regulator potassium acetate of part and the water of 0.5 weight part, feed to a 52 type twin-screw extruder after mixing uniformly and be used for extruding the middle layer of three-layer structure PVB;

[0060] (2) the anti-blocking agent erucamide of 0.51 parts by weight, the anti-blocking agent silicon stearate of 0.5 parts by weight, the PVB resin powder of 72 parts by weight, the plasticizer 3GO of 26 parts by weight, the ant...

Embodiment 3

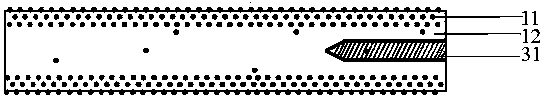

[0067] Add anti-blocking agent during the forming process of PVB film, spray anti-blocking agent when PVB film leaves the mold for thermal stretching and expansion, and manufacture anti-blocking single-layer PVB film that does not need isolation film protection when the temperature is greater than 10°C. The specific process is as follows:

[0068] ⑴With the anti-blocking agent oleyl palmitic acid amide of 0.01 weight part, the PVB resin powder of 72 weight parts, the 3GO plasticizer of 26 weight parts, the 1010 antioxidant of 0.2 weight part, the 328 ultraviolet absorber of 0.2 weight part, 0.09 parts by weight of potassium acetate knock value regulator and 0.5 parts by weight of water, after mixing, feed to a 95 type twin-screw extruder for producing this PVB film, and the feeding speed is 99 parts by weight / minute;

[0069] ⑵95 extruder and other equipment form a PVB production line;

[0070] (3) The temperature of the screw area of the 95 extruder is set from low to high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com