Two-dimensional tellurium nano-sheet as well as preparation method and application thereof

A tellurium nanometer and ultrasonic technology, applied in the field of two-dimensional tellurium nanosheets and its preparation, can solve the problems of restricting the development of two-dimensional functional materials and limited types of two-dimensional layered materials, and achieve excellent photoelectric detection performance, good peeling effect, The effect of the simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the embodiment of the present invention provides a method for preparing two-dimensional tellurium nanosheets, comprising the following steps:

[0037] A tellurium raw material is provided, and the tellurium raw material is stripped by a liquid phase exfoliation method to obtain two-dimensional tellurium nanosheets, and the thickness of the two-dimensional tellurium nanosheets is 1-50 nm.

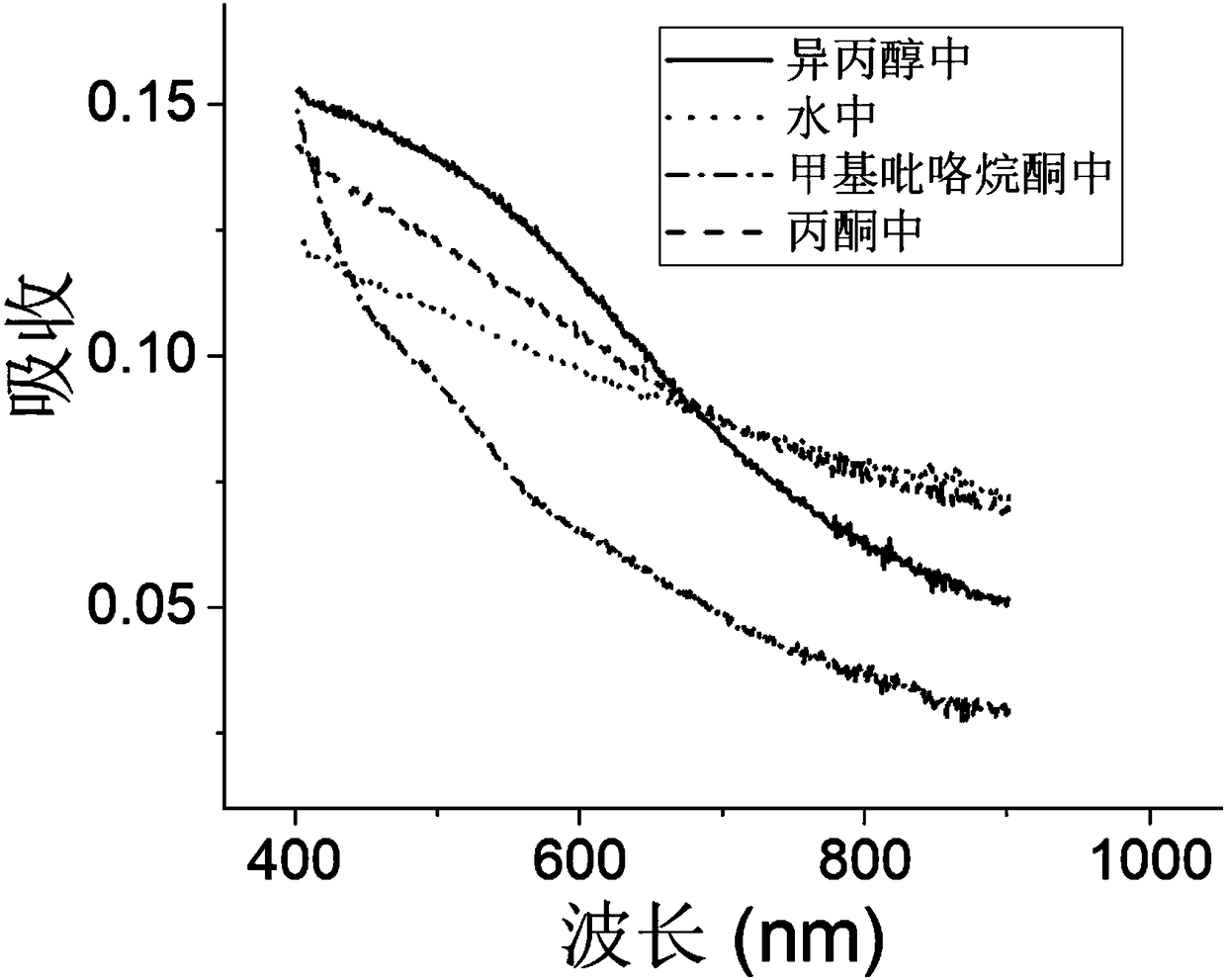

[0038] In the embodiment of the present invention, the tellurium raw material is a two-dimensional non-layered metal tellurium element, such as tellurium powder, or a tellurium block, and there is no special limitation on its size and shape, for example, it can be micron-scale or millimeter-scale blocks. The tellurium raw material can be purchased. The bandgap of the tellurium raw material is as narrow as about 0.3eV, and the bandgap of the two-dimensional tellurium nanosheets obtained after stripping is also narrower, which can be used to detect light with a lon...

Embodiment 1

[0055] A method for preparing two-dimensional tellurium nanosheets, comprising the following steps:

[0056] (1) Add 500mg of tellurium powder into 100ml of isopropanol. Then select the probe ultrasound 240W, ultrasound 10h. The ultrasonic on / off time was selected as 2 / 4s, and the ultrasonic was performed in an ice bath environment. After the probe is sonicated, the water bath is then used for sonication. The ultrasonic power of the water bath is 360W. Ultrasonic time is 8h. The temperature of the water bath was maintained at 10°C;

[0057] (2) After ultrasonication, centrifugation is used to obtain the required two-dimensional tellurium nanosheets. Firstly, a centrifugal force of 2000g is used for 30min. The supernatant was taken, and then the supernatant was continuously centrifuged at 12000 g for 30 min to obtain a precipitate, which was then vacuum-dried to obtain two-dimensional tellurium nanosheets.

[0058] Such as figure 1 Shown is the electron microscope topog...

Embodiment 2

[0062] A method for preparing two-dimensional tellurium nanosheets, comprising the following steps:

[0063] (1) Add 500mg of tellurium powder into 100ml of isopropanol. Then select the probe ultrasound 200W, ultrasound 15h. The ultrasonic on / off time was selected as 2 / 4s, and the ultrasonic was performed in an ice bath environment. After the probe is sonicated, the water bath is then used for sonication. The ultrasonic power of the water bath is 300W. Ultrasonic time is 10h. The temperature of the water bath was maintained at 15°C;

[0064] (2) After ultrasonication, centrifugation is used to obtain the required two-dimensional tellurium nanosheets. Firstly, the centrifugal force of 1800g is adopted, and the centrifugation is performed for 35min. The supernatant was taken, and then the supernatant was centrifuged at 15000 g for 25 minutes to obtain a precipitate, which was dried in vacuum to obtain two-dimensional tellurium nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com