High-strength and anti-tearing bamboo and manufacturing technology thereof

A manufacturing process, anti-tearing technology, applied in the direction of manufacturing tools, wood processing appliances, wood layered products, etc., can solve the problems of easy tearing and splitting, easy cracking stability, poor shear resistance, etc., to achieve enhanced Nail-holding effect, improvement of nail-holding power, and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

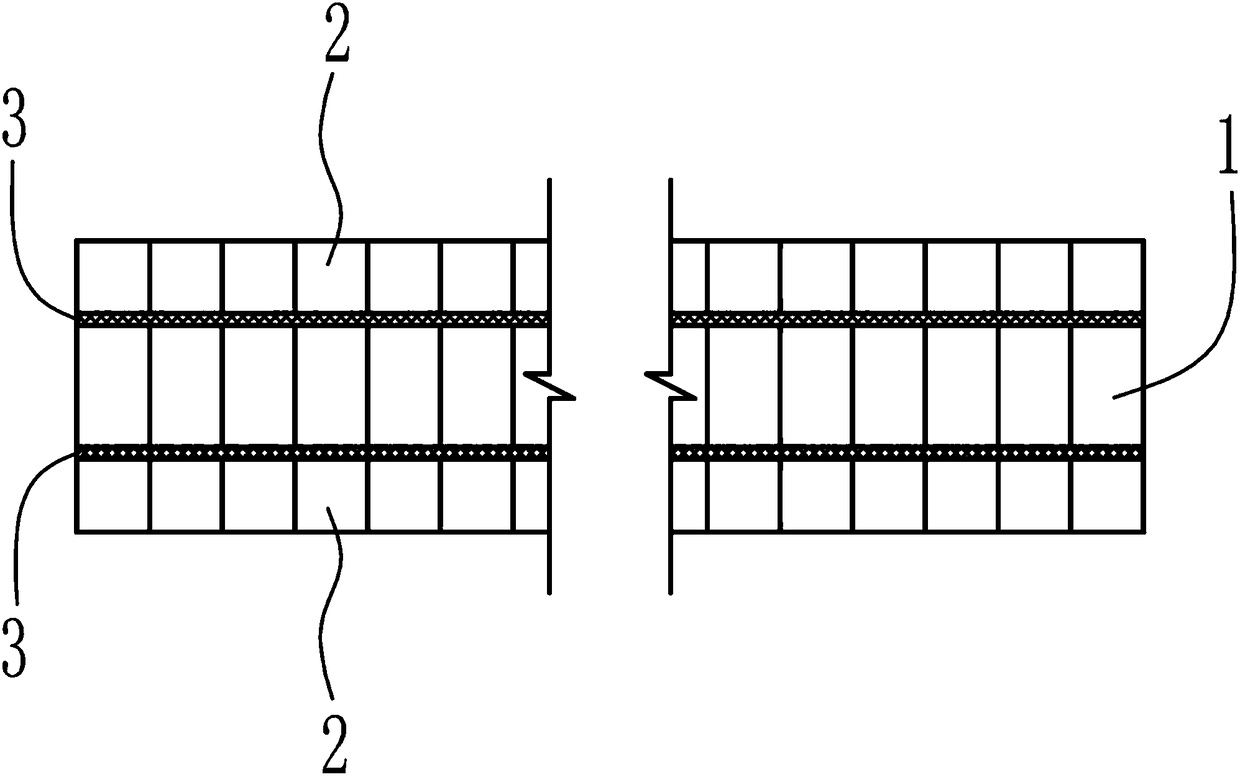

[0029] The technical solution provides a high-strength tear-resistant bamboo material, the bamboo material includes a bamboo base material 1, a bamboo plate material 2 and a fiber cloth 3, the middle part of the bamboo material is the bamboo material material 1, and the bamboo material material 1 is a layer Side-pressed bamboo board, the outside of the bamboo is a bamboo board 2, the bamboo board 2 is a layer of side-pressed bamboo board or flat-pressed bamboo board, the bamboo board 2 is located on the outer surface arranged in the same direction as the bamboo base material 1, and the bamboo base material 1 A fiber cloth 3 is arranged between the bamboo board 2, and the bamboo substrate 1, the bamboo board 2 and the fiber cloth 3 are fixed to each other by hot pressing with an adhesive.

[0030] When the bamboo substrate 1 is a layer of side-pressed bamboo board, the bamboo board 2 is also a layer of side-pressed bamboo board, and when the bamboo board 2 is located on the oute...

Embodiment 2

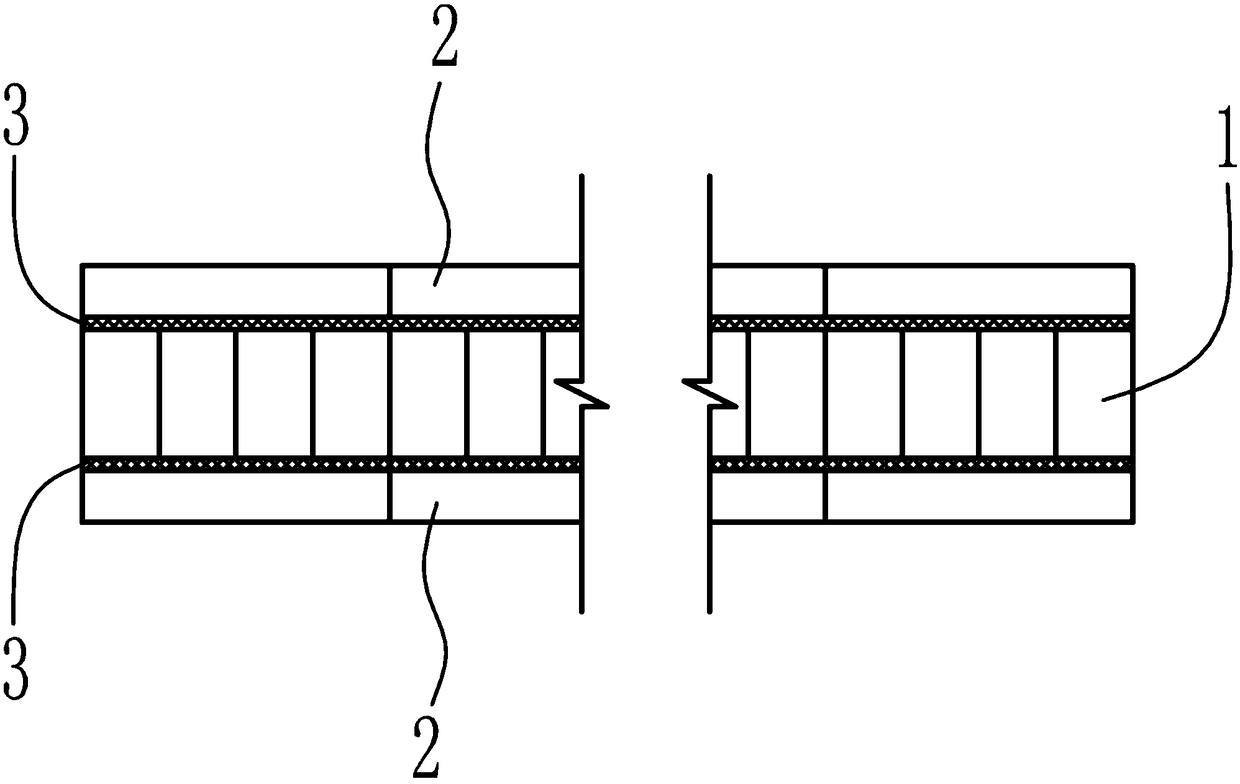

[0034] The technical solution provides a high-strength tear-resistant bamboo material, the bamboo material includes a bamboo base material 1, a bamboo plate material 2 and a fiber cloth 3, the middle part of the bamboo material is the bamboo material material 1, and the bamboo material material 1 is a composite bamboo material Board or more than two layers of side-pressed bamboo boards arranged in the same direction, the outside of the bamboo is a bamboo board 2, and the bamboo board 2 is a layer of side-pressed bamboo boards, and the bamboo board 2 is located on the four sides of the bamboo base 1 or in the same direction as the bamboo base. The outer surfaces of the materials 1 are arranged in the same direction, and the fiber cloth 3 is arranged between the bamboo base material 1 and the bamboo board material 2, and the bamboo base material 1, the bamboo board material 2 and the fiber cloth 3 are fixed to each other by hot pressing with an adhesive.

[0035] When the bamboo ...

Embodiment 3

[0039] This technical scheme provides a kind of high-strength tear-resistant bamboo manufacturing process, and its steps are: according to such as figure 1 The structure shown, that is, the bamboo substrate 1 is a layer of side-pressed bamboo board, and the bamboo board 2 is also a layer of side-pressed bamboo board, and the bamboo board 2 is located on the outer surface arranged in the same direction as the bamboo substrate 1, and on the bamboo base The fiber cloth 3 is added to the contact surface between the bamboo material 1 and the bamboo board 2, and the bamboo base material 1, the bamboo board 2 and the fiber cloth 3 are hot-pressed and fixed to each other through an adhesive, and the hot-pressing temperature is 130°C. , the hot pressing pressure is 15MPa, and the hot pressing time is 18min.

[0040] Processing obtains bamboo sample 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com