Cooling device for laser welding

A cooling device and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of polluting the lens and achieve the effect of preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

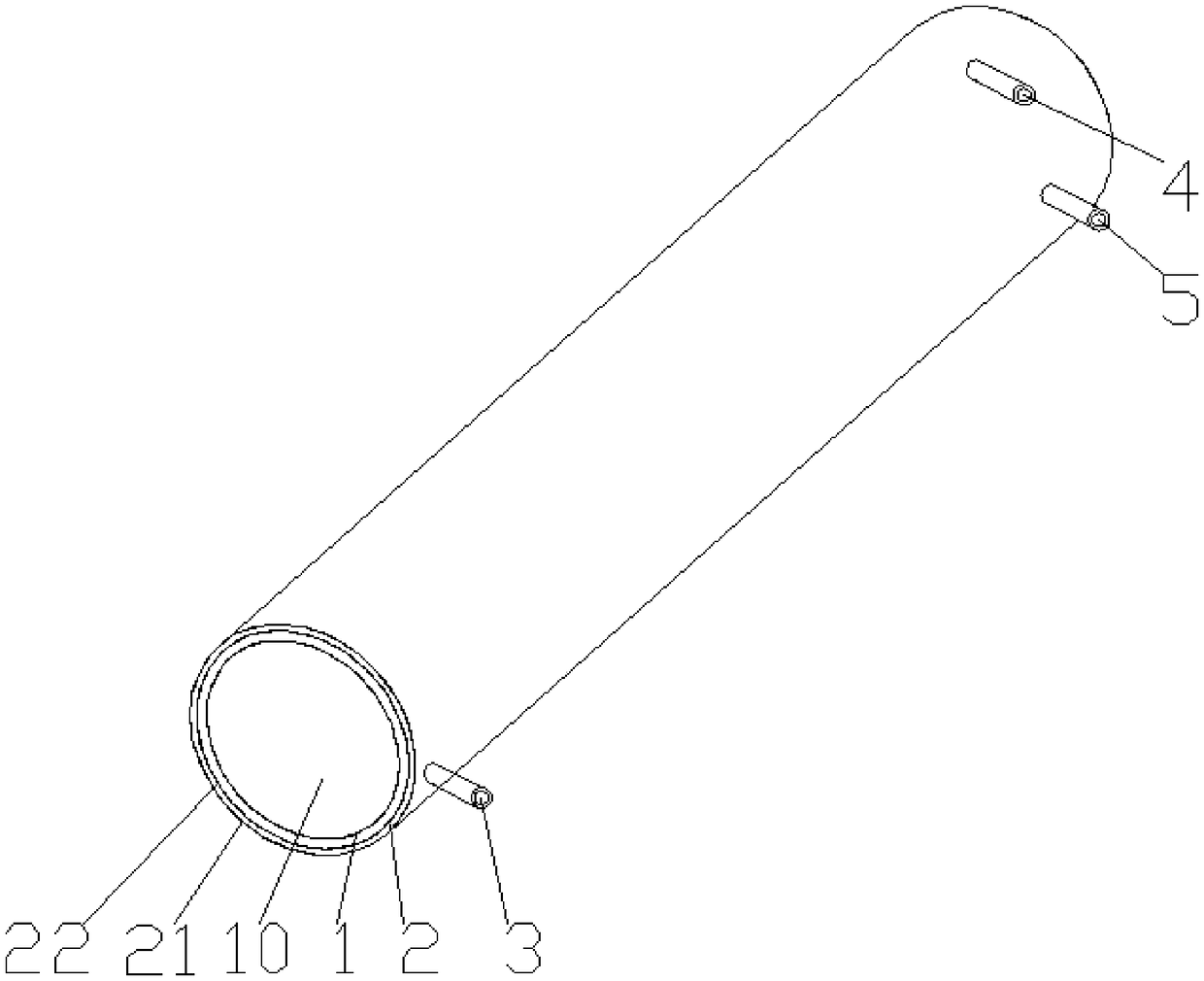

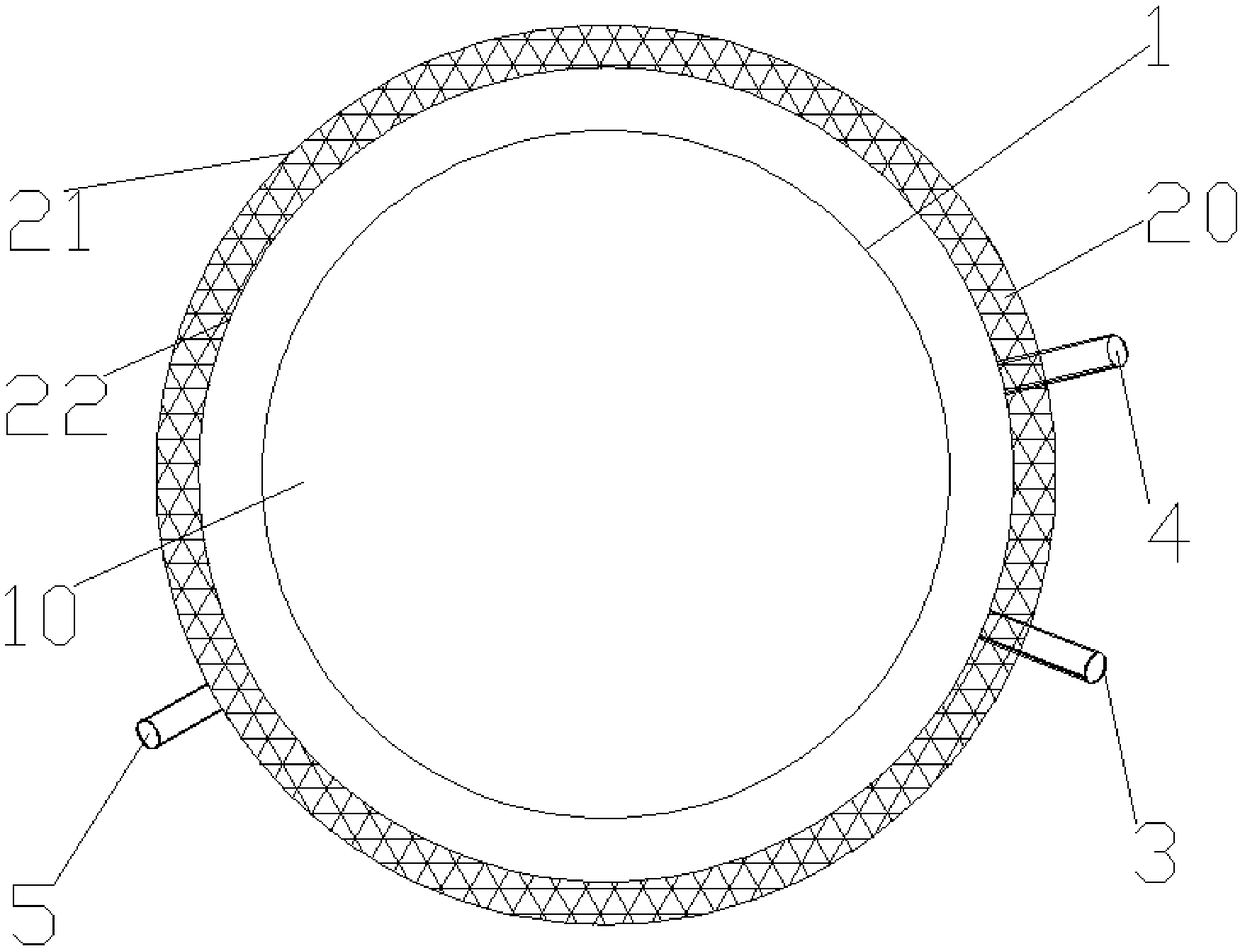

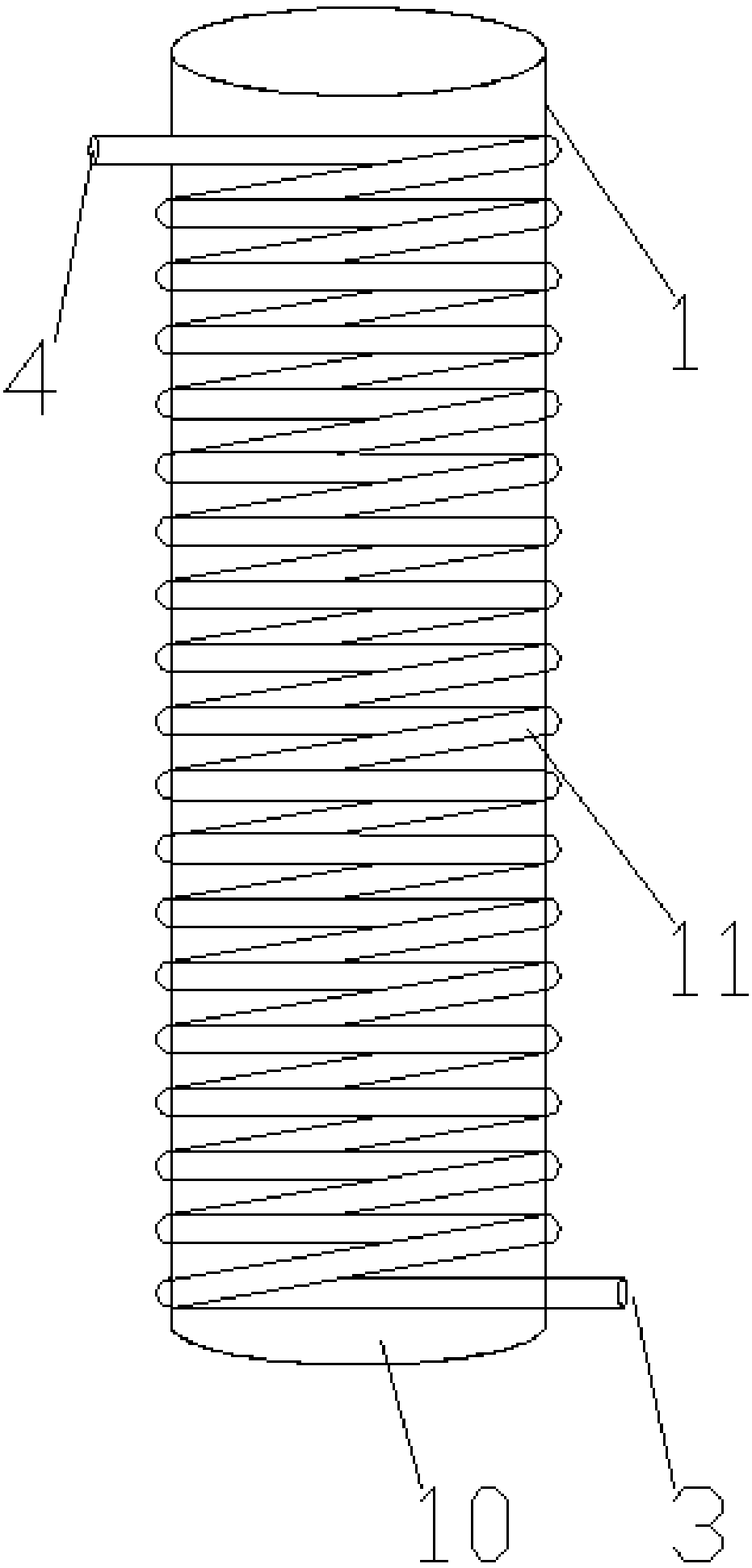

[0018] Such as Figure 1 to Figure 4 As shown, a cooling device for laser welding includes a light pipe 10, a cavity 2, a water inlet pipe 3, an outlet pipe 4, and an air intake pipe 5. The light pipe 10 is composed of a light pipe shell 1; the light pipe shell There is a coil pipe 11 outside the body 1; the coil pipe 11 is a half pipe and the lower part is connected with the water inlet pipe 3, and the upper part is connected with the water outlet pipe 4; the cavity 2 is formed as an annular air channel by the cavity outer wall 21 and the cavity inner wall 22; The upper part of the outer wall 21 of the cavity is connected with the air intake pipe 5; the cavity 2 is closely connected with the coil tube 11, and the lower part of the cavity is provided with an isolation net 20.

[0019] According to the above-mentioned structure, when the laser welding machine is working, the cooling device of laser welding is connected with the laser generator 30 and the laser welding nozzle 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com