Titanium alloy bar welding method

A welding method and titanium alloy technology, applied in welding equipment, welding accessories, welding/welding/cutting items, etc., can solve the problems of incomplete penetration fusion, inability to meet the quality requirements of radiographic flaw detection, and deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

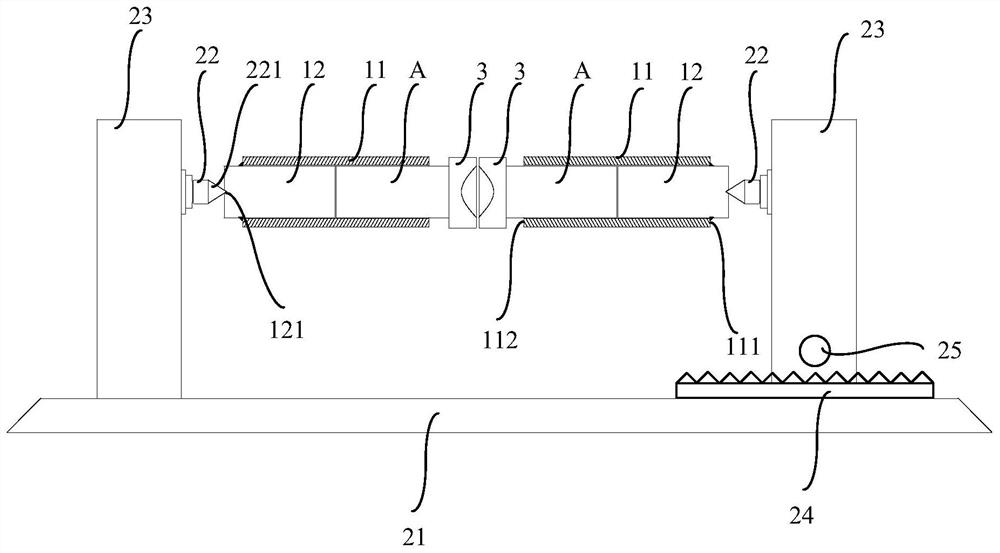

[0025] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

[0026] In the related art, when titanium alloy rods are welded, the end faces of two titanium alloy rods to be welded (that is, welded joints) are triangular, so that after the two titanium alloy rods are relatively butted, a double-sided groove can be formed. to be welded.

[0027] According to the technical requirements, the titanium alloy bar needs to be inspected by radiograph after welding, which requires NB / T47013-2015 Class I qualification, and the straightness of the welded titanium alloy bar is ≤1.5mm.

[0028] In the related art, usually after rooting welding is performed on one side of the double-sided groove of the titanium alloy rod, root cleaning is performed on the other side of the double-sided groove to ensure the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com