Intelligent air compressor base positioning tool for serial bulk vehicle and application method

A technology for positioning tooling and air compressors, used in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of reduced production efficiency, low work efficiency, and difficult assembly, and achieve the effect of high-efficiency compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

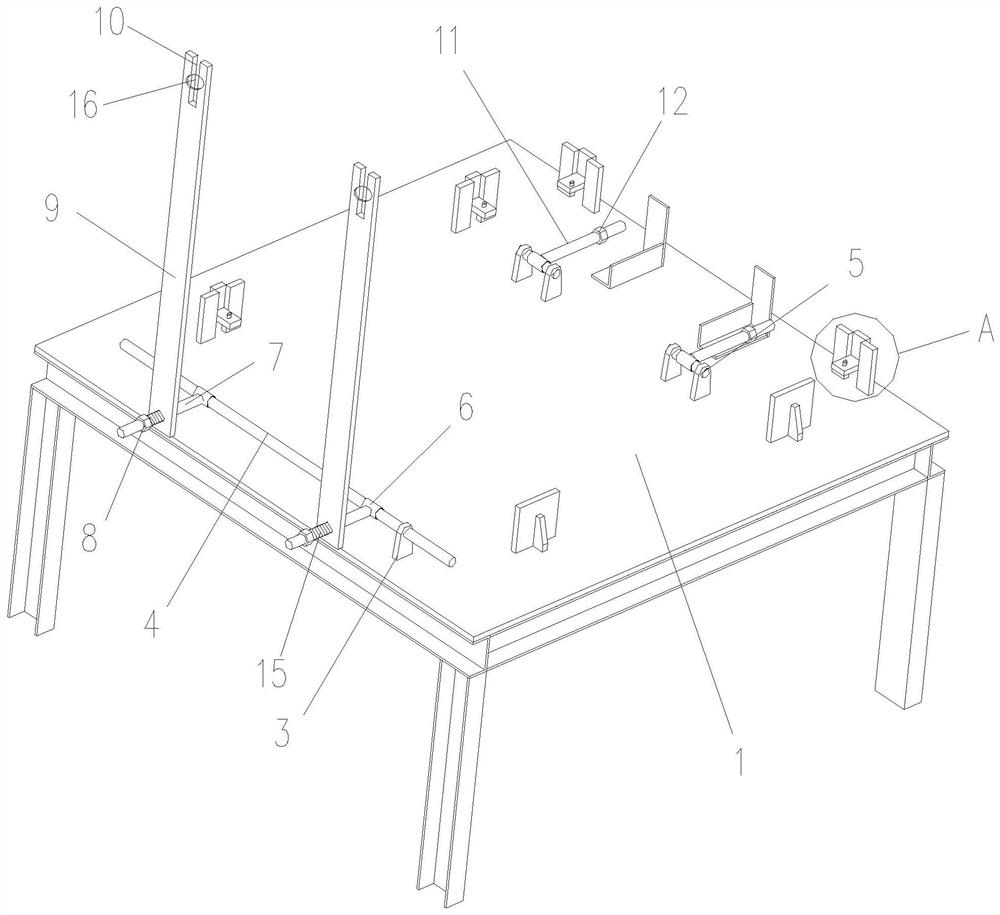

[0032] Such as Figure 1 to Figure 3 As shown, the intelligent series bulk vehicle air compressor base positioning tooling includes a working platform 1 on which a limiting plate 2, a pressing unit and a locking unit are installed, and the pressing unit includes a fixing seat 3 , a rotating shaft 4 and a pressing structure, the fixed seat 3 is fixedly connected to the left side of the upper surface of the working platform 1, the rotating shaft 4 is installed on the fixing seat 3, and the rotating shaft 4 is provided with a pressing structure, so The locking unit includes a fixed seat 2 5 and a locking structure, the fixed seat 2 5 is fixedly connected to the right side of the upper surface of the working platform 1, and the fixed seat 2 5 is rotatably connected with a locking structure, through the pressing After the tight structure presses the base of the air compressor, it is fitted and connected with the locking structure and locked. Rotate the compression structure to the...

Embodiment 2

[0039] Such as Figure 4 As shown, the difference from Embodiment 1 is that the upper surface of the pressure plate 9 located at the connecting notch 10 is fixedly connected with a wedge-shaped block 13, and the adjustment rod 2 11 is overlaid with a wedge-shaped block 1 13. The second wedge block 14, the first wedge block 13 and the second wedge block 14 prevent the adjustment rod two 11 from disengaging from the connection notch 10. Wedge block one 13, wedge block two 14 are used in conjunction with nut two 12, nut one 8 and connection notch 10 to be able to realize more efficient compression effect, can also guarantee simultaneously that pressing plate is in horizontal state after compression.

[0040] In a further preferred solution in this embodiment, a compression spring 15 is sleeved on the adjustment rod 7 , and the compression spring 15 is arranged between the pressure plate 9 and the nut 8 . It can ensure the compression effect of the device and the horizontal effec...

Embodiment 3

[0042] The method of using the intelligent series bulk truck air compressor base positioning tool includes the following steps:

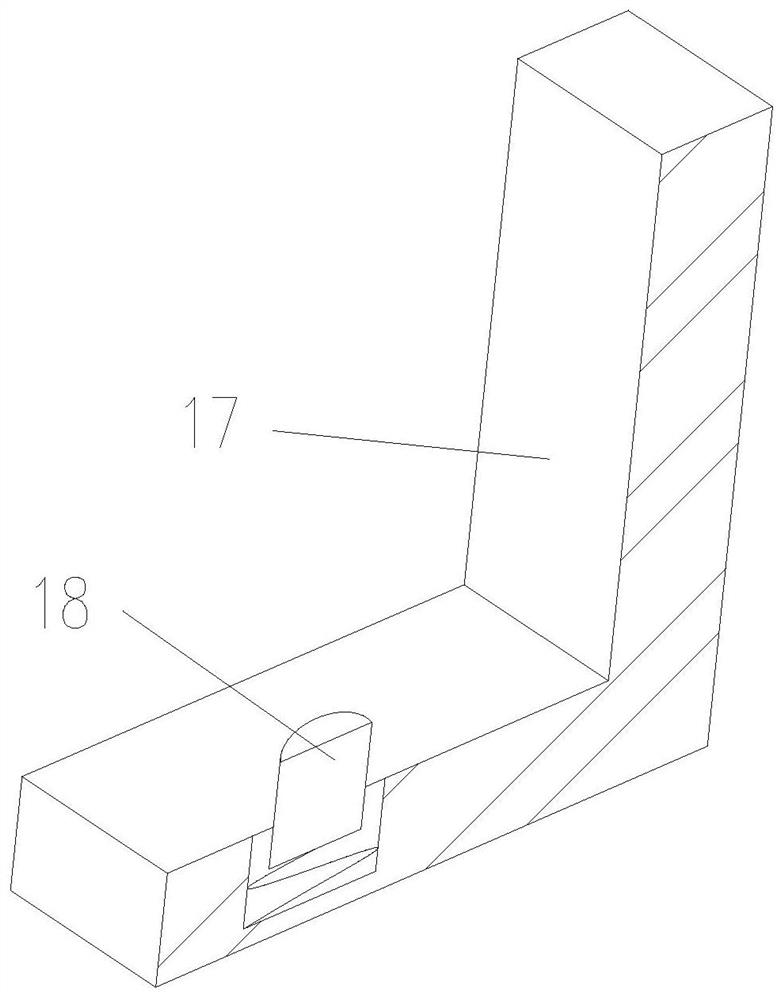

[0043] A. First, install the base of the air compressor on the working platform 1 according to the position of the limit plate 2. When installing, the base of the air compressor first pushes the horizontal part of the sub-plate 17 to make it rotate. When it rotates to 90 degrees, the horizontal part becomes In a vertical state, the vertical part becomes a horizontal state and limits the lower part of the air compressor base under the action of the pusher 18;

[0044] B. Then adjust the nut one 8 to the proper position first, then rotate the adjustment rod one 7, the adjustment rod one 7 rotates through the sleeve 6 and the rotating shaft 4, until the pressure plate 9 is placed flat on the upper part of the air compressor base;

[0045] C. Adjust nut two 12 to a suitable position, and then rotate the adjustment rod two 11 so that the adjustment rod t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com