An integrated equipment for drying and sorting stale garbage

A technology for equipment and garbage, which is applied in the field of integrated equipment for drying and sorting stale garbage, can solve the problems of low efficiency of stale garbage, and achieve the effect of improving drying and air separation effects, and reducing heat loss and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

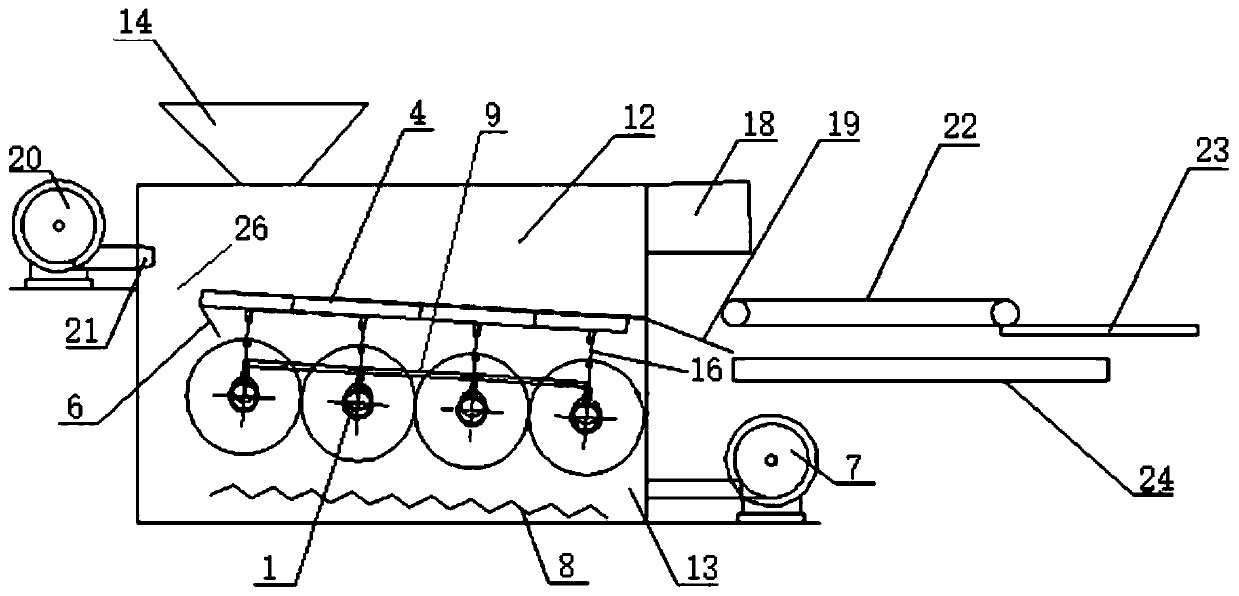

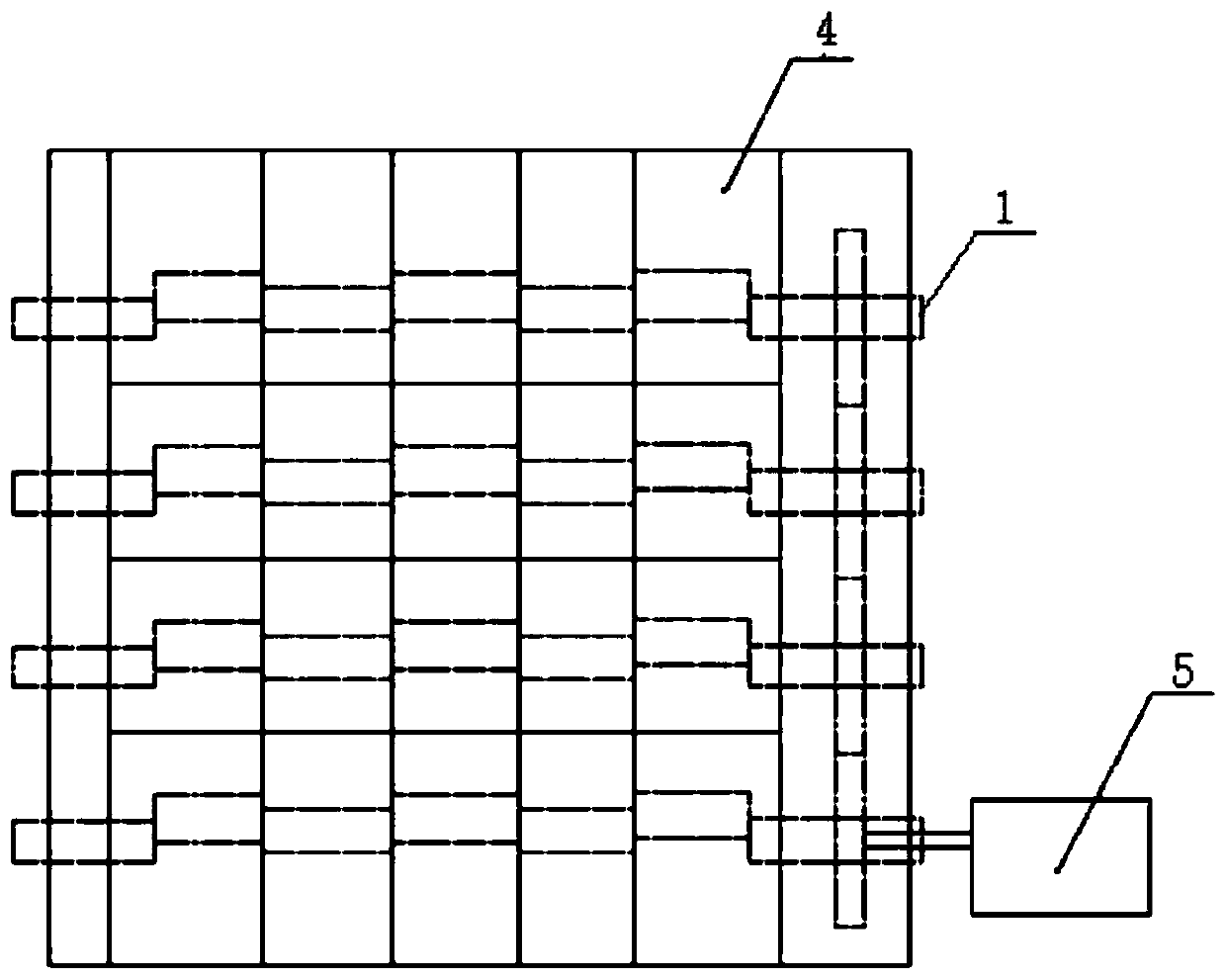

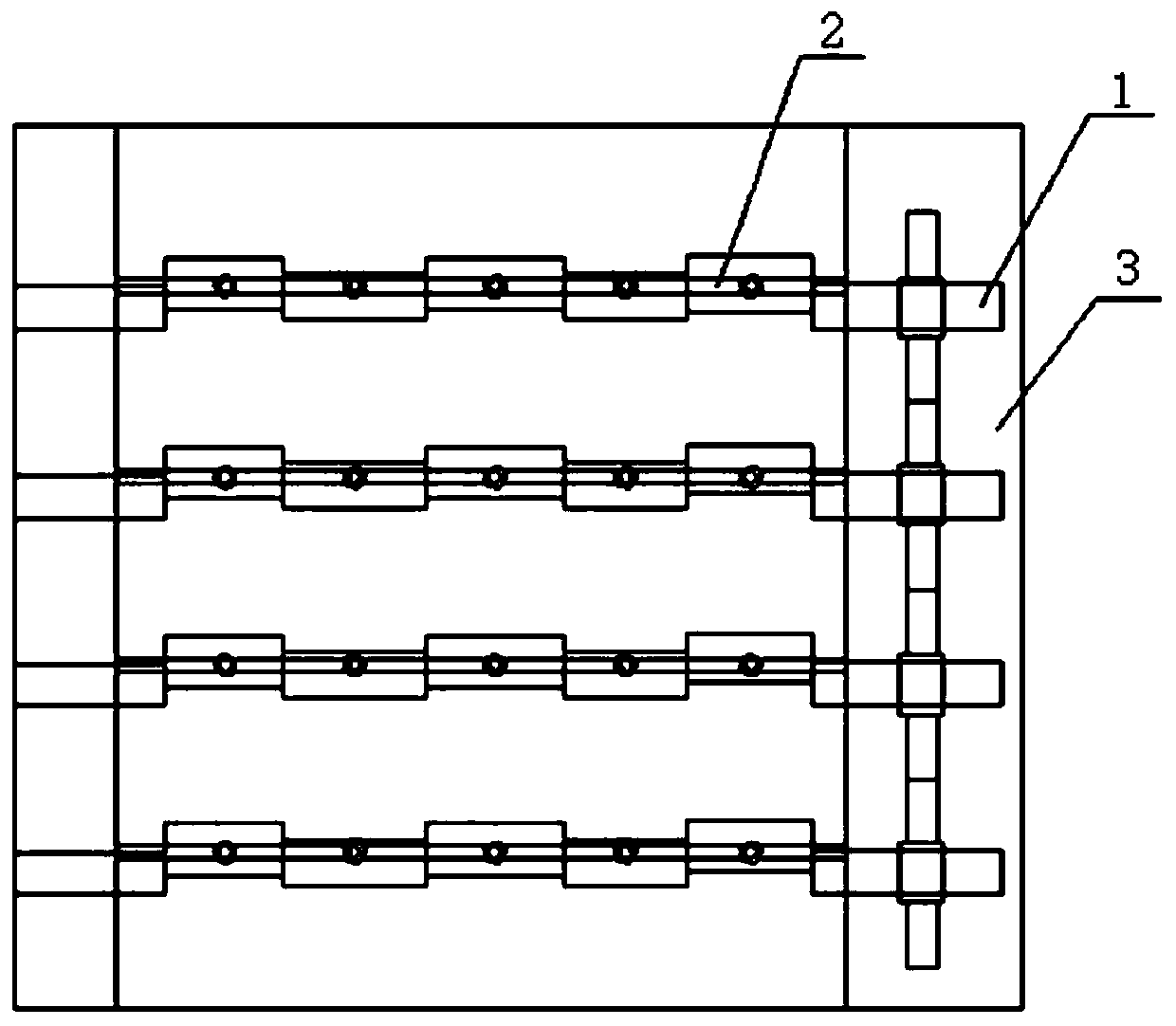

[0038] see Figure 1-5 , the stale garbage drying and sorting integrated equipment in the illustration is the preferred solution of the present invention, which specifically includes a camshaft 1, a fixed frame 2, a frame 3, a unit plate 4, a driving motor 5, a deflector 6, and a lower blower 7. Heating part 8, linkage rod 9, unit plate connecting hinge 10, flat key 11, blanking and sorting cavity 12, drying heating cavity 13, feeding hopper 14, crank connecting rod 15, connecting rod 16, roller 17. Light material discharge port 18, heavy material discharge port 19, upper blower 20, airflow speed-increasing variable diameter pipe 21, magnetic separator 22, metal conveyor belt 23, garbage conveyor belt 24 and hot air channel 25.

[0039] The main body of the equipment is provided with three inlet and outlet passages: a feed hopper 14, a light material discharge port 18 and a heavy material discharge port 19, wherein the feed hopper 14 is used to feed the broken stale garbage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com