A kind of stepped pore macroporous-mesoporous alumina carrier and its preparation method

A technology of mesoporous alumina and stepped pores, which is applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc. It can solve the complex preparation process of alumina materials containing impurities, and it is difficult to prepare high-performance alumina materials, etc. Problems, to achieve short reaction cycle, improve circulation and diffusion performance, and slow down the effect of carbon deposition and deactivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing a stepped pore macroporous-mesoporous alumina carrier, comprising the following steps:

[0041] Add 20 mL of sec-butanol solution with a mass fraction of 99.5% in the beaker, and add 6 mL of deionized water into the beaker, mix well, take the supernatant, and add 2 g of aluminum sec-butoxide solution evenly dropwise to the supernatant (97wt%), generate white precipitate, after slowly stirring 3min with glass rod, leave standstill 3min, then stir 10min;

[0042] The product was subjected to suction filtration, and the product obtained by suction filtration was placed in an oven at 60°C and left to stand for 12 hours to obtain a white powder;

[0043] The powder is calcined in a muffle furnace at a high temperature of 550° C. for 4 hours to obtain a stepped-pore macroporous-mesoporous alumina carrier.

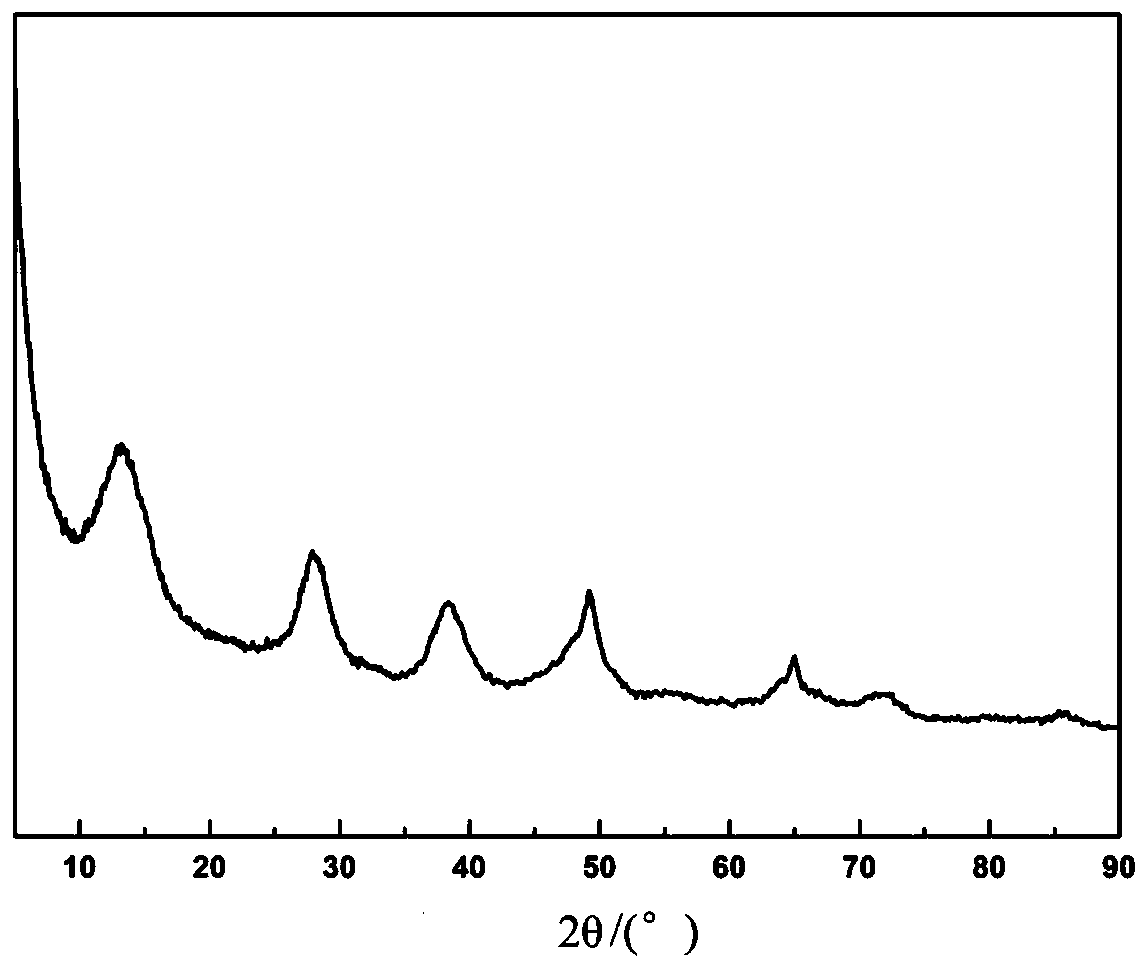

[0044] figure 1 For the X-ray diffraction pattern of the product obtained in this example, the main diffraction peaks of ...

Embodiment 2

[0046] This embodiment provides a method for preparing a stepped pore macroporous-mesoporous alumina carrier, comprising the following steps:

[0047]Adding 20mL of mass fraction in the beaker is 99.5% butanol solution, and adding 4mL of deionized water in the beaker, after mixing evenly, get the supernatant, and evenly dropwise add 2g of aluminum sec-butoxide solution in the supernatant ( 97wt%), generate a white precipitate, after slowly stirring with a glass rod for 3min, leave it for 3min, and then stir for 10min;

[0048] The product was subjected to suction filtration, and the product obtained by suction filtration was placed in an oven at 60°C and left to stand for 12 hours to obtain a white powder;

[0049] The powder was calcined in a muffle furnace at a high temperature of 550° C. for 6 hours to obtain a stepped macroporous-mesoporous alumina carrier.

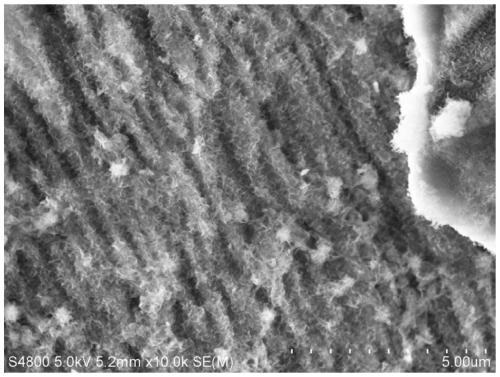

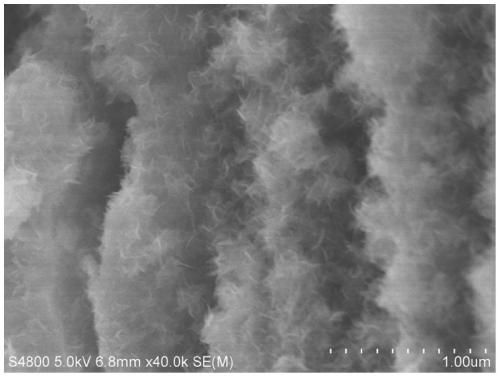

[0050] Figure 2a (5μm) and Figure 2b (1 μm) is the scanning electron microscope image of the carrier in this e...

Embodiment 3

[0052] This embodiment provides a method for preparing a stepped pore macroporous-mesoporous alumina carrier, comprising the following steps:

[0053] Adding 20mL of mass fraction in the beaker is 99.5% butanol solution, and in the beaker, add 3mL of deionized water, get the supernatant after mixing evenly, and evenly drop 2g of aluminum sec-butoxide solution in the supernatant ( 97wt%), generate a white precipitate, after slowly stirring with a glass rod for 3min, leave it for 3min, and then stir for 10min;

[0054] The product was subjected to suction filtration, and the product obtained by suction filtration was placed in an oven at 60°C and left to stand for 12 hours to obtain a white powder;

[0055] The powder was calcined in a muffle furnace at a high temperature of 550° C. for 4 hours to obtain a stepped-pore macroporous-mesoporous alumina carrier.

[0056] image 3 This is the nitrogen adsorption-desorption isotherm curve of the carrier in this example, and the exis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com