A hierarchical macroporous-mesoporous γ-al loaded noble metal 2 o 3 Catalyst and its preparation method

A graded pore, precious metal technology, applied in the field of graded pore macroporous-mesoporous γ-Al2O3 catalyst and its preparation, can solve the problems of poor pore structure, uneven loading of active components, complicated preparation process, etc., and achieve excellent pores. Structural and pore properties, the effect of improving flow diffusivity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

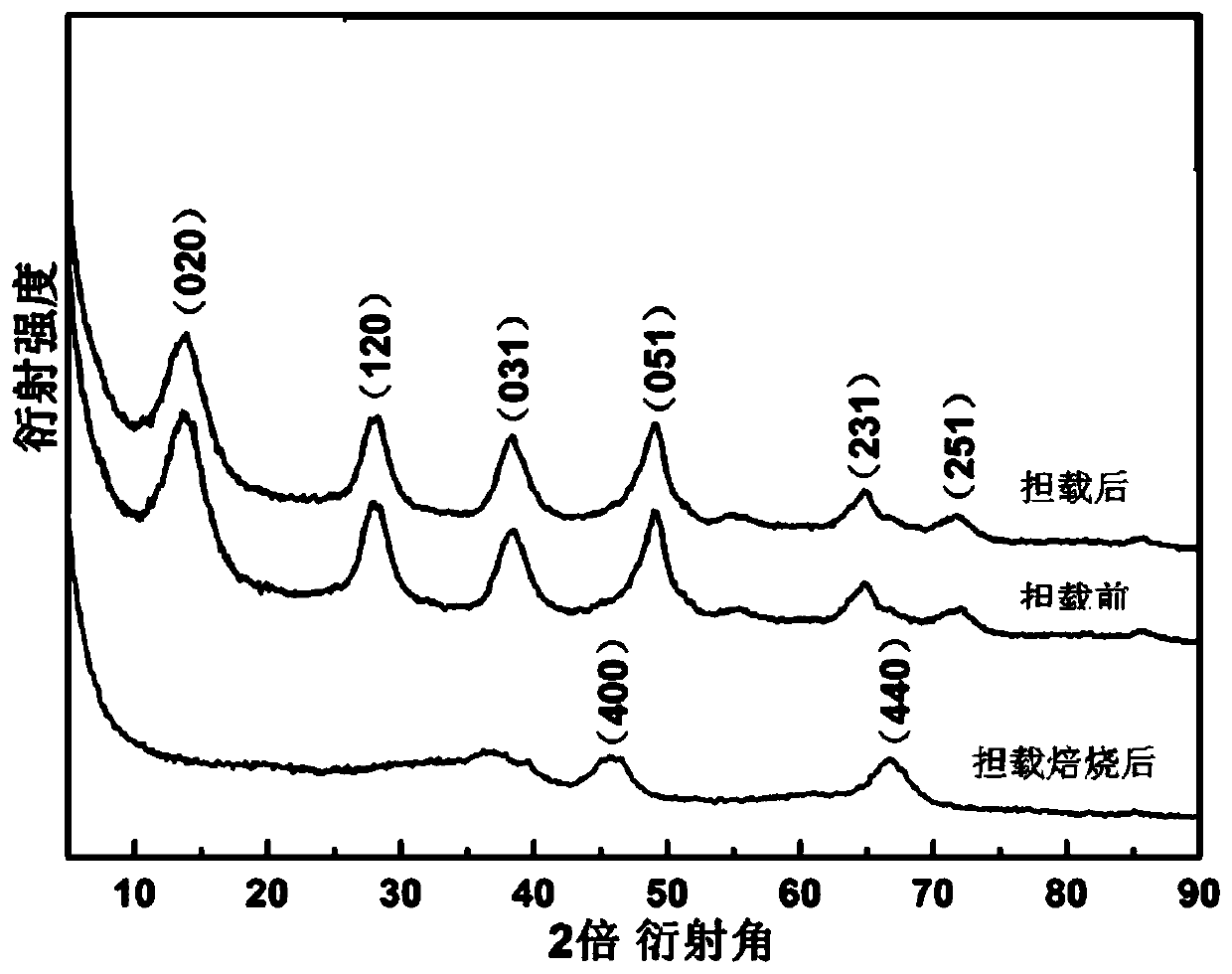

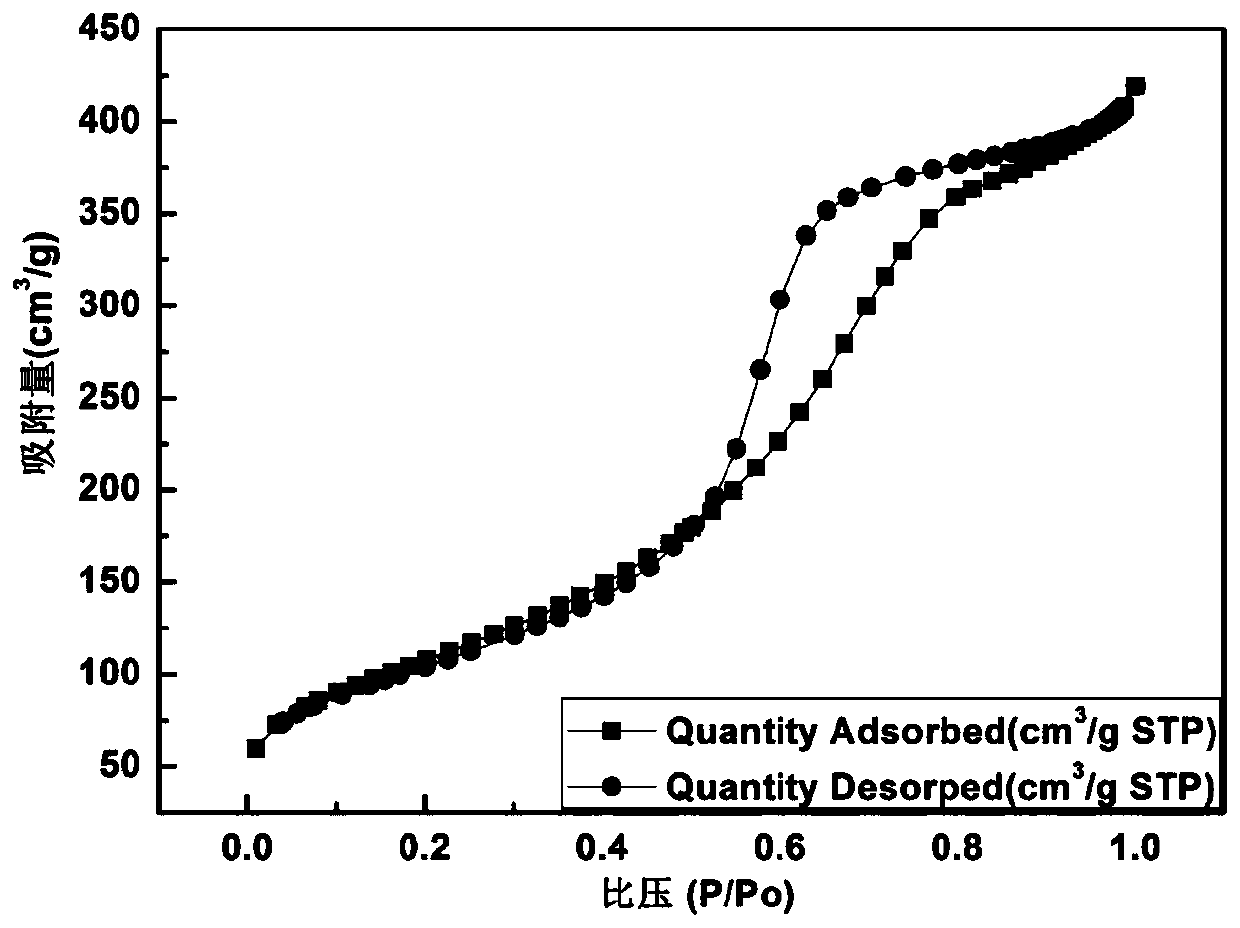

[0046] A hierarchical macroporous-mesoporous γ-Al loaded with noble metals 2 o 3 Catalyst, its preparation method comprises the steps:

[0047] 1) Add 3mL of deionized water to the acetonitrile solution (20ml, 99.5wt%, relative density ρ=0.79), stir evenly to obtain an aqueous solution of acetonitrile, and then uniformly drop 2g of aluminum sec-butoxide solution (97wt%, relative density ρ=0.967), found to generate white precipitate immediately, under the condition of 25 ℃, after standing for 10min, use magnetic stirrer to stir 10min under the rotating speed of 100r / min, then stand for 10min, get white precipitate I;

[0048] 2) The white precipitate I obtained in step 1) is subjected to suction filtration, and the product obtained by suction filtration is placed in an oven at 60° C., left to stand for 12 hours and fully dried to obtain a white powder, which is used as a loaded precursor (macroporous-mesoporous AlOOH Precursor);

[0049] 3) Under the condition of 25℃, 1g H ...

Embodiment 2

[0053] A hierarchical macroporous-mesoporous γ-Al loaded with noble metals 2 o 3 Catalyst, its preparation method comprises the steps:

[0054] 1) Add 3mL of deionized water to the acetonitrile solution (20ml, 99.5wt%, relative density ρ=0.79), stir evenly to obtain an aqueous solution of acetonitrile, and then uniformly drop 2g of aluminum sec-butoxide solution (97wt%, relative density ρ=0.967), found to generate white precipitate immediately, under the condition of 25 ℃, after standing for 10min, use magnetic stirrer to stir 10min under the rotating speed of 100r / min, then stand for 10min, get white precipitate I;

[0055] 2) The obtained white precipitate I obtained in step 1) is subjected to suction filtration, and the product obtained by suction filtration is placed in a 60° C. Porous AlOOH precursor);

[0056] 3) Add 1g H 2 PtCl 6 ·6H 2 O powder dissolved in 250ml H 2 O, after stirring evenly, drop into 1mL hydrochloric acid solution (concentration is 0.05mol / L) t...

Embodiment 3

[0060] A hierarchical macroporous-mesoporous γ-Al loaded with noble metals 2 o 3 Catalyst, its preparation method comprises the steps:

[0061] 1) Add 4mL of deionized water to the acetonitrile solution (20ml, 99.5wt%, relative density ρ=0.79), stir evenly to obtain an aqueous acetonitrile solution, and then uniformly drop 2g of aluminum sec-butoxide solution (97wt%, relative density ρ=0.967), found to generate white precipitate immediately, under the condition of 25 ℃, after standing for 10min, use magnetic stirrer to stir 10min under the rotating speed of 100r / min, then stand for 10min, get white precipitate I;

[0062] 2) Suction filter the white precipitate I product obtained in step 1), put the product obtained by suction filtration into an oven at 60°C, and let it stand for 12 hours to fully dry to obtain a white powder, which is used as a loading precursor (macropore-mesopore AlOOH precursor);

[0063] 3) Add 1g H 2 PtCl 6 ·6H 2 O powder dissolved in 250ml H 2 O,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com