Method for measuring content of SBS modifier in SBS modified asphalt

A technology of modified asphalt and modifier is applied in the field of measuring the content of SBS modifier in SBS modified asphalt, which can solve the problems of dark color, non-uniformity and low light transmittance of modified asphalt, and achieve a small sample size. , High stability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

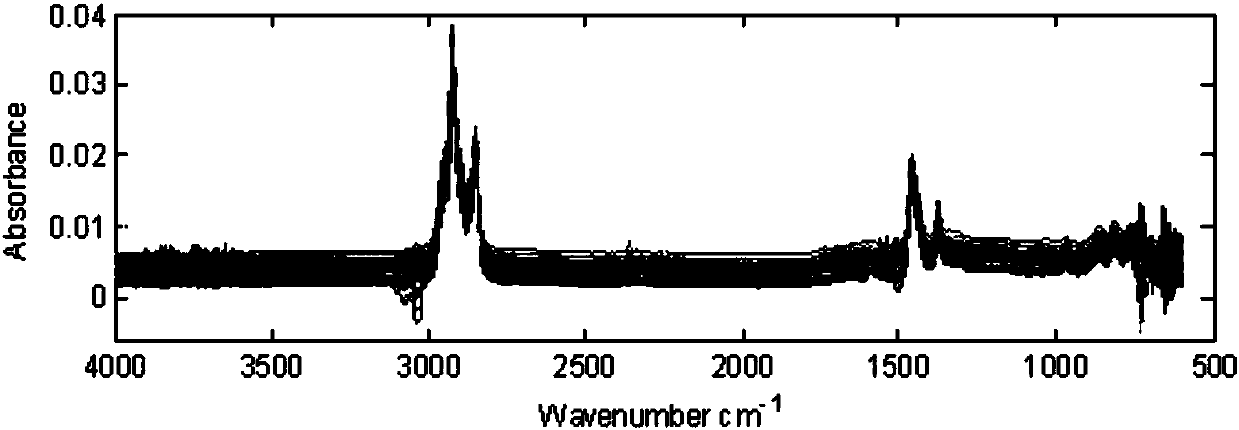

[0036] A method for measuring SBS modifier content in SBS modified asphalt, comprising the following steps:

[0037] Step 1, prepare the infrared test sample of SBS modified asphalt standard sample

[0038]Potassium bromide tablets were prepared by tablet-dissolving film method: 20.0000 g of SBS modified asphalt standard samples were weighed, and the content of SBS modifier accounted for 3.500%, 4.000%, 4.500% and 5.000% of the mass of SBS modified asphalt respectively. %, put it in a clean beaker, and slowly inject 200mL of toluene, stir to fully dissolve the SBS modified asphalt to obtain a stirring liquid; immerse the pre-prepared potassium bromide tablet in the above stirring liquid and let it stand for 30 minutes, then Take out the soaked potassium bromide pellets and place them on a bracket, put them into an oven with a vacuum device, and dry them at 60°C to prepare uniform potassium bromide pellets containing standard samples of SBS modified asphalt.

[0039] Step 2, p...

Embodiment 2

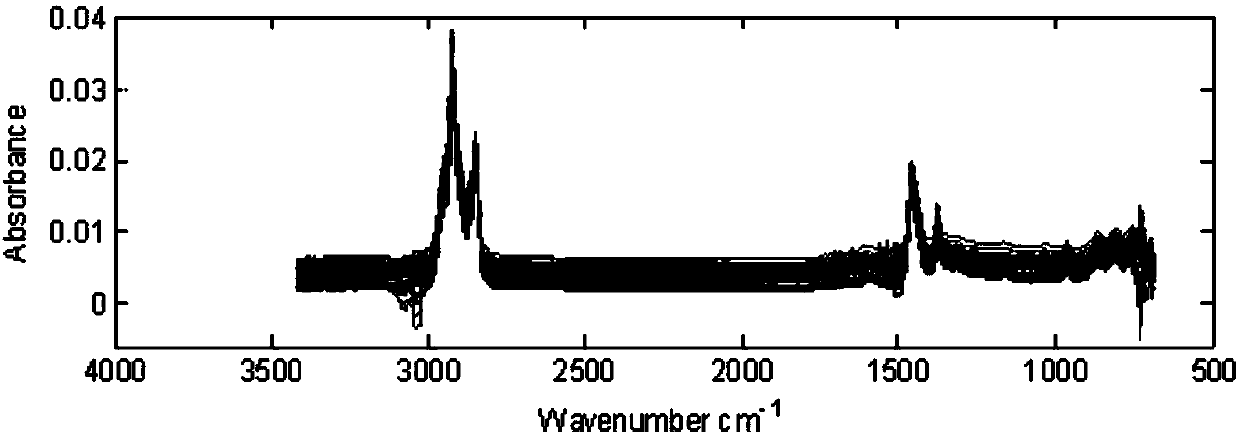

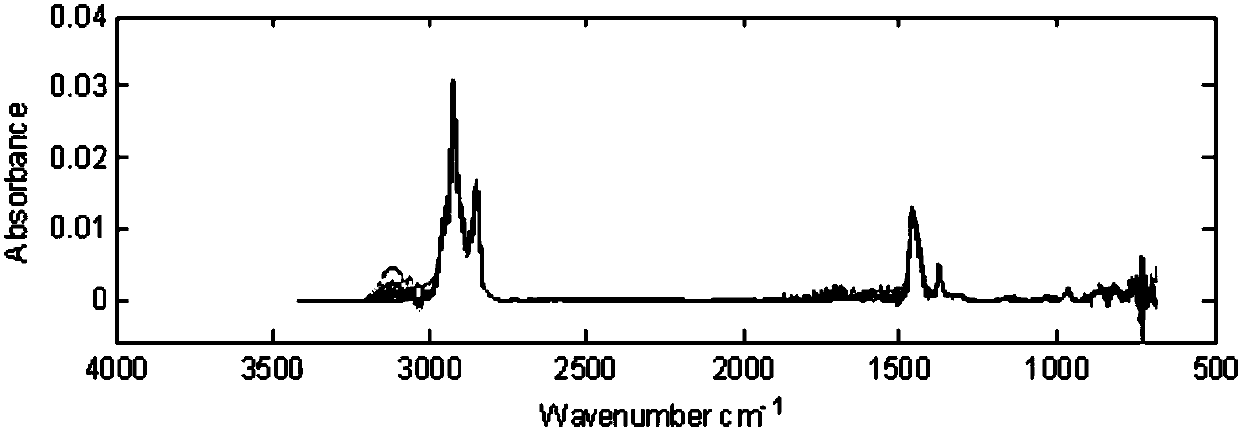

[0069] A method for measuring SBS modifier content in SBS modified asphalt, comprising the following steps:

[0070] Step 1, prepare the infrared test sample of SBS modified asphalt standard sample

[0071] Potassium bromide tablets were prepared by tablet-dissolving film method: 20.0000 g of SBS modified asphalt standard samples were weighed, and the content of SBS modifier accounted for 3.500%, 4.000%, 4.500% and 5.000% of the mass of SBS modified asphalt respectively. %, put it in a clean beaker, and slowly inject 200mL of toluene, stir to fully dissolve the SBS modified asphalt to obtain a stirring liquid; immerse the pre-prepared potassium bromide tablet in the above stirring liquid and let it stand for 30 minutes, then Take out the soaked potassium bromide pellets and place them on a bracket, put them into an oven with a vacuum device, and dry them at 60°C to prepare uniform potassium bromide pellets containing standard samples of SBS modified asphalt.

[0072] Step 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com