A kind of method for measuring rhodium content in bisphosphine ligand rhodium catalyst

A technology of rhodium catalyst and bisphosphine ligand, which is applied in the direction of measurement device, test sample preparation, color/spectral characteristic measurement, etc. It can solve the problems of unreported, cumbersome steps, complicated operation, etc., and shorten the processing time , good repeatability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Microwave digestion treatment of the sample: Weigh 0.10 g of the bisphosphine ligand rhodium catalyst and add it to the digestion tank, add 8 mL of nitric acid solution, put it into the microwave digestion instrument, set the digestion program for digestion, and perform acid removal treatment after the sample digestion is completed , cooled to room temperature, set aside, and make a blank at the same time.

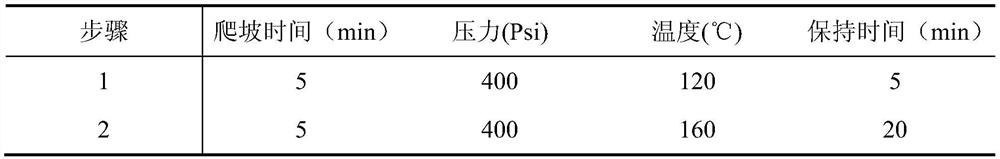

[0026] Table 1 Microwave digestion program

[0027]

[0028] (2) Preparation of sample solution: Dilute the solution cooled to room temperature in step (1) with 1% nitric acid to prepare blank and sample solutions, dilute the blank and sample solutions, add 1mL LaCl 3 After the solution is constant volume, it is the solution to be tested.

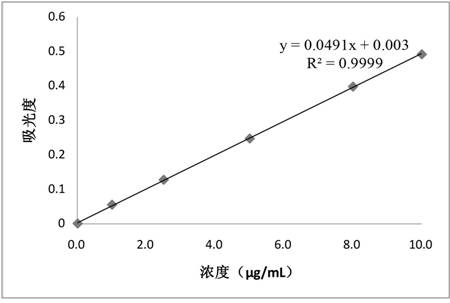

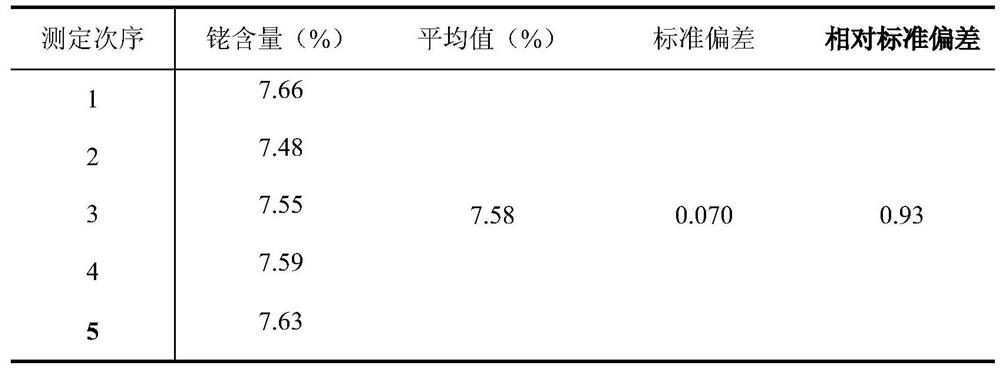

[0029] (3) Preparation of rhodium standard solution: the rhodium standard solution with a concentration of 1000 μg / mL was diluted with 1% dilute nitric acid to 100 μg / mL for later use. A series of rhodium standard soluti...

Embodiment 2

[0036] Microwave digestion treatment of samples: Weigh 0.20g of bisphosphine ligand rhodium catalyst into the digestion tank, add 12mL of nitric acid, put it into the microwave digestion instrument, set the digestion program for digestion, after the sample digestion is completed, carry out acid removal treatment, and cool to room temperature , spare, and blank at the same time.

[0037] Table 3 Microwave digestion program

[0038]

[0039] (2) Preparation of sample solution: Dilute the solution cooled to room temperature in step (1) to prepare blank and sample solutions, dilute the blank and sample solutions with 5% dilute nitric acid, add 1mL LaCl 3 After constant volume, it is the solution to be tested.

[0040] (3) Preparation of rhodium standard solution: the rhodium standard solution with a concentration of 1000 μg / mL was diluted with 5% dilute nitric acid to 100 μg / mL for later use. A series of rhodium standard solutions with concentrations of 0.0, 1.0, 2.5, 5.0, 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com