Nanocomposite plugging agent for drilling shale horizontal wells and preparation method thereof

A nano-composite, horizontal well technology, applied in the field of oil drilling, can solve the problems of weak plugging performance, limited plugging effect, and insufficient compactness of filter cake, etc., and achieve good plugging performance and inhibition, stable product performance, and temperature resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

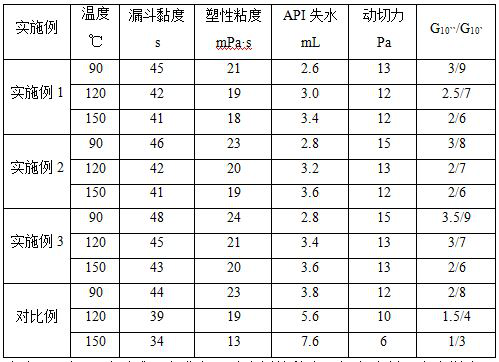

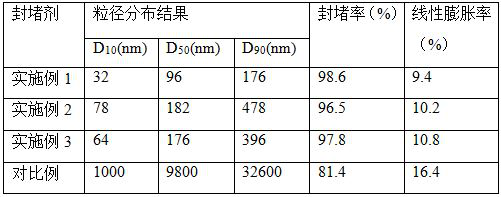

Examples

Embodiment 1

[0020] 1. A nanocomposite plugging agent for drilling into shale horizontal wells, consisting of the raw materials of the following parts by weight: 20 parts of nanoemulsions, 3 parts of nano silicon dioxide, 10 parts of polyethylene glycol, 20 parts of polyalcohols,

[0021] Wherein, the nanoemulsion is prepared by mixing solid paraffin, white oil, emulsifier, and water in a weight ratio of 2:2:1:5, and stirring for 1 h at 80° C. and a stirring speed of 120 rpm;

[0022] The hydrophilic-lipophilic balance value of the emulsifier is 10.3, which is composed of Tween 80:Span 80=56:44 in weight ratio;

[0023] The cloud point temperature of the polymeric alcohol is 65°C, which is prepared by the following method: dodecyl dimethyl tertiary amine, ethylene oxide, and propylene oxide in a weight ratio of 1.2:400:280 It is prepared by mixing and then reacting for 4 hours under the conditions of 0.3MPa and 150°C.

[0024] 2. The preparation method of the above-mentioned nano-composit...

Embodiment 2

[0026] 1. A nanocomposite plugging agent for drilling into shale horizontal wells, made up of the raw materials of the following parts by weight: 30 parts of nanoemulsions, 8 parts of nano silicon dioxide, 20 parts of polyethylene glycol, 30 parts of polyalcohols,

[0027] Wherein, the nanoemulsion is prepared by mixing solid paraffin, white oil, emulsifier, and water in a weight ratio of 2:2:1:5, and stirring for 1 h at 80° C. and a stirring speed of 120 rpm;

[0028] The hydrophilic-lipophilic balance value of the emulsifier is 10.3, which is composed of Tween 80:Span 80=56:44 in weight ratio;

[0029] The cloud point temperature of the polymeric alcohol is 65°C, which is prepared by the following method: dodecyl dimethyl tertiary amine, ethylene oxide, and propylene oxide in a weight ratio of 1.2:400:280 It is prepared by mixing and then reacting for 4 hours under the conditions of 0.3MPa and 150°C.

[0030] 2. The preparation method of the nanocomposite plugging agent for...

Embodiment 3

[0032] 1. A nanocomposite plugging agent for drilling into shale horizontal wells, consisting of the raw materials of the following parts by weight: 25 parts of nanoemulsions, 5 parts of nano silicon dioxide, 15 parts of Polyethylene Glycol, 25 parts of polyalcohols,

[0033] Wherein, the nanoemulsion is prepared by mixing solid paraffin, white oil, emulsifier, and water in a weight ratio of 2:2:1:5, and stirring for 1 h at 80° C. and a stirring speed of 120 rpm;

[0034] The hydrophilic-lipophilic balance value of the emulsifier is 10.3, which is composed of Tween 80:Span 80=56:44 in weight ratio;

[0035] The cloud point temperature of the polymeric alcohol is 65°C, which is prepared by the following method: dodecyl dimethyl tertiary amine, ethylene oxide, and propylene oxide in a weight ratio of 1.2:400:280 It is prepared by mixing and then reacting for 4 hours under the conditions of 0.3MPa and 150°C.

[0036] 2. The preparation method of the nanocomposite plugging agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com