Passive frequency control material based on graphene/ferrite and preparation method of passive frequency control material

A graphene and ferrite technology, applied in the field of wave absorbing materials, can solve problems such as no articles and reports, and achieve the effects of reliable performance, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The invention provides a preparation method of a graphene / ferrite-based passive frequency control material, the preparation method comprising the following steps: (1) preparing a graphene solution by using a redox process.

[0053] The preparation methods of graphene mainly include micromechanical exfoliation method, chemical vapor deposition method, crystal epitaxy orientation growth method, liquid phase exfoliation method, graphite oxide reduction method, etc. The advantage of the micromechanical exfoliation method is that it is simple and not easy to produce structural defects, but the output is too low, the area is too small, it is difficult to accurately control, the efficiency is low, and it is difficult to achieve large-scale preparation; And the vacuum conditions are high, the thickness of the graphene film using this method is often uneven, and the graphene is tightly adhered to the substrate, which greatly affects the performance of the graphene. Chemical vapor ...

Embodiment 1

[0070] S1, prepare graphene solution, comprise the steps:

[0071] S11, 30g natural flake graphite, 10g NaNO 3 Add it to 500mL of concentrated sulfuric acid with a concentration of 18mol / L, put it in an ice-water bath, stir for 30min, and make it fully mixed;

[0072] S12, weigh 70g KMnO 4 Add to the mixed solution in S11, stir for 2h;

[0073] S13. The temperature of the solution obtained in S12 is raised to 30° C., and the stirring is continued for 30 minutes;

[0074] S14. Slowly add 100 mL of distilled water to the solution obtained in S13, raise the temperature to 95° C., and stir for 30 min;

[0075] S15, adding 40mL of 30% H to the mixed solution obtained in S14 2 o 2 Stir continuously for 2 hours, dilute with 100mL distilled water, and filter at 90°C;

[0076] S16. Wash the solution of S15 with a 5% concentration of dilute hydrochloric acid solution and distilled water until there are no sulfate groups, and add 100 mL of distilled water for ultrasonic dispersion ...

Embodiment 2

[0103] The preparation method is basically the same as Example 1, except that:

[0104] In S4, balls with a diameter of 3 mm were used, the ball-to-material ratio was 6:1, the speed of the ball mill was 700 r / min, and the ball milled for 4 hours.

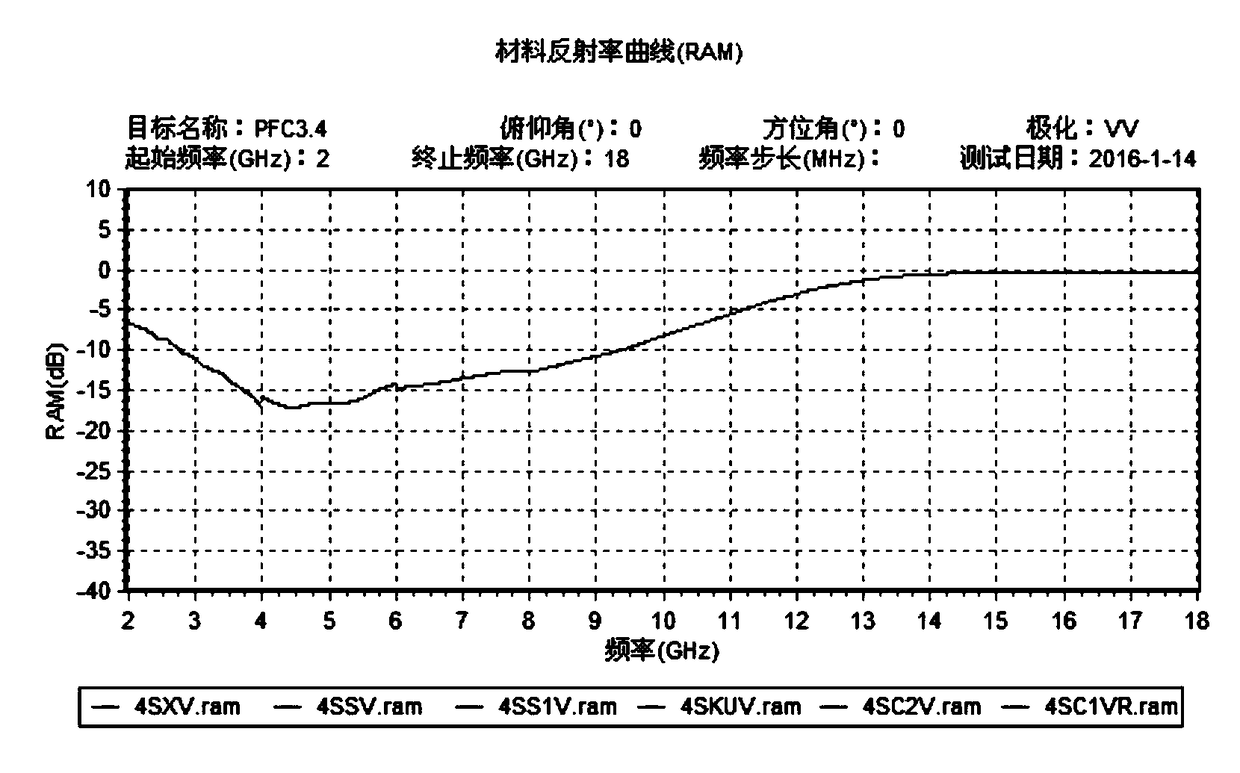

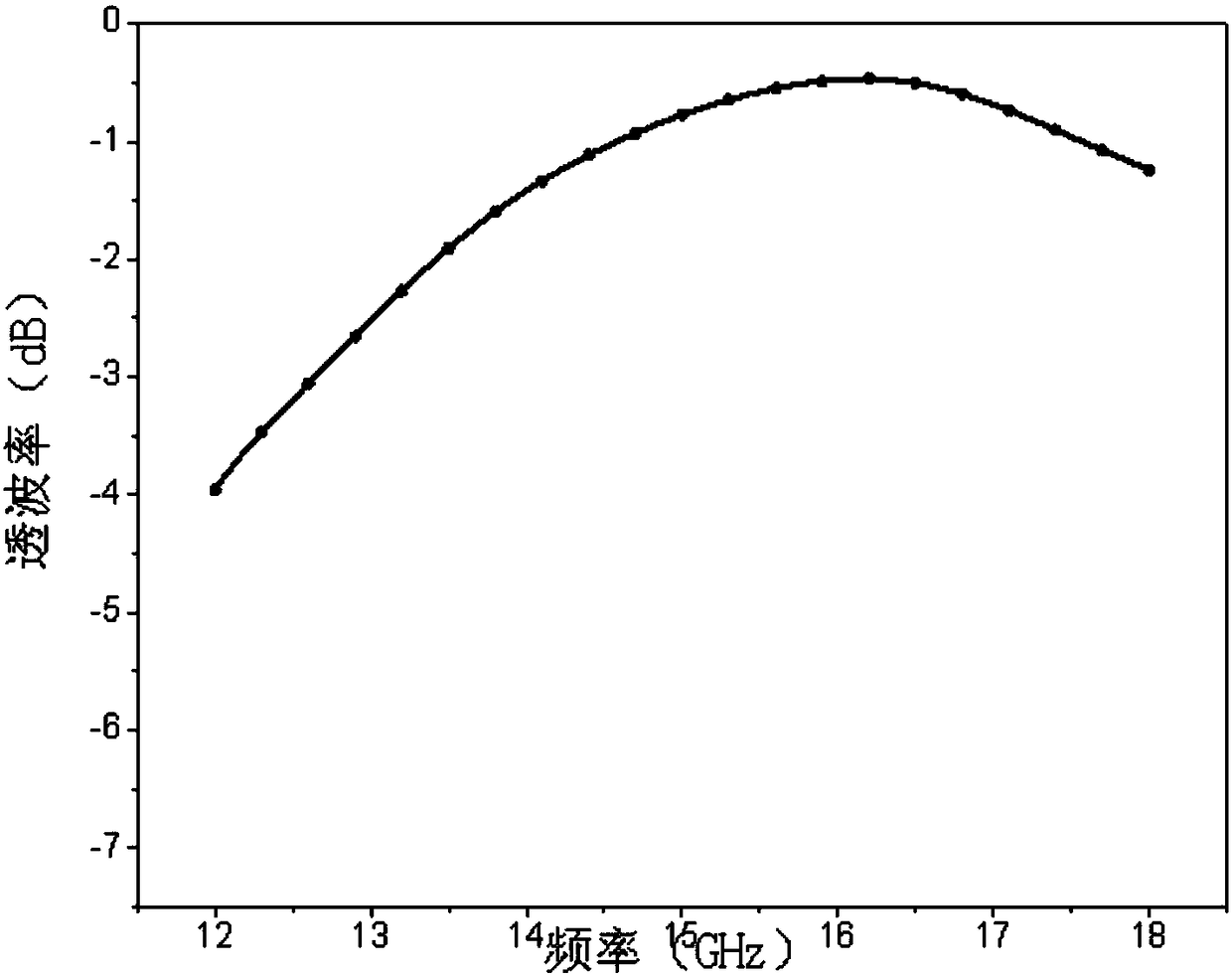

[0105] The reflectance of the material prepared in this embodiment is detected, and it is known that the reflectance of the material in the wide frequency range of 2 GHz to 18 GHz can reach -15 dB at least, and has very good absorbing performance. In the frequency range of 15GHz to 17GHz, the maximum wave transmission rate can reach -0.4dB, which has very good wave transmission performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com