Airflow suspension type screening machine

A suspension type and screening machine technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve problems such as filter blockage, achieve quality assurance, good effect, and low processing and production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

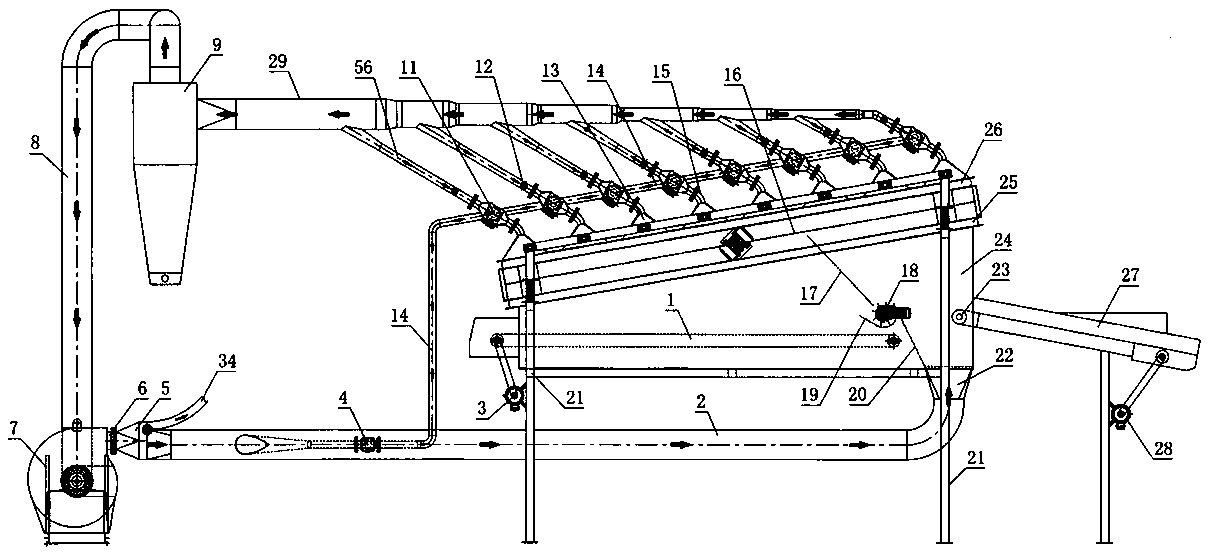

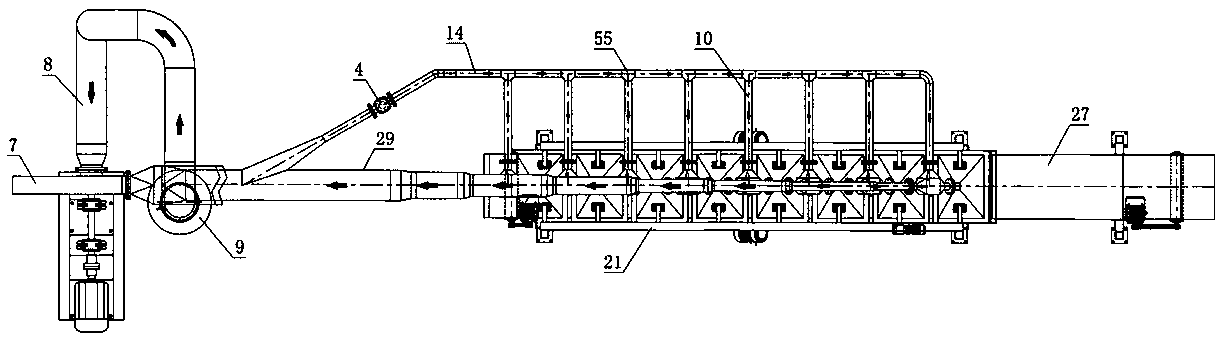

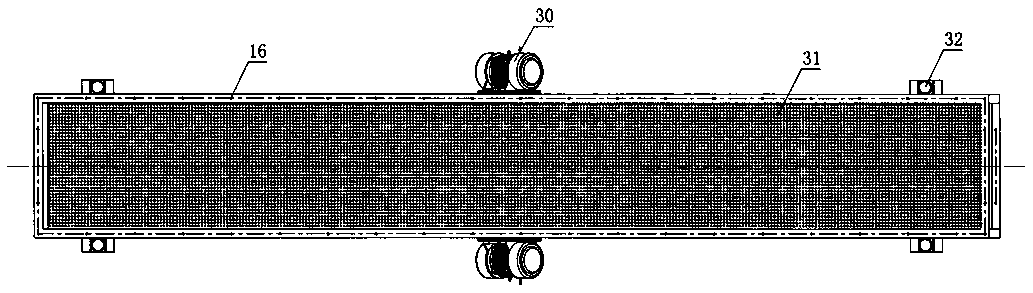

[0017] Figure 1-7 The upper end of the frame 21 shown in the figure is provided with a screen box 24, the upper end of the screen box 24 is provided with a lower sealing cover 25, the upper end of the lower sealing cover is provided with a vibrating screen device 16, and the upper end of the vibrating screen device 16 is provided with an upper Sealing cover 26, the upper end of upper sealing cover is provided with 6-20 suction outlets 13, and the upper end of suction outlet 13 is provided with suction connection pipe 15, and the upper end of suction connection pipe 15 is provided with pneumatic adjustment three-way valve 11, suction connection pipe 15 It is connected by flange to the lower valve port 49 of the pneumatic regulating three-way valve 11, the upper end of the pneumatic regulating three-way valve is provided with an exhaust branch pipe 56, the air volume regulating valve 12 is arranged on the exhaust branch pipe 56, and the left end of the frame 21 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com